Rapid prototyping has become an indispensable part of product development, yet its cost range varies widely—from tens to tens of thousands of dollars—often causing confusion among teams. This article delves deeply into the core logic of cost composition, combining professional insights with practical strategies to help you precisely control budgets and maximize the return on investment in prototyping.

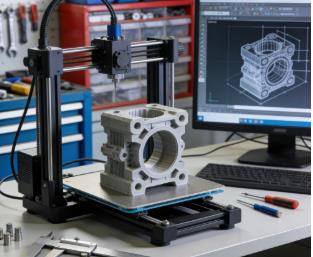

1. What is Rapid Prototyping?

Rapid Prototyping is the process of quickly transforming digital models into physical samples using technologies such as 3D printing and CNC machining. It is not only a critical step for validating designs, testing functions, and gathering feedback, but also a core investment that reduces risks in mass production and accelerates product time-to-market.

The cost is not a single figure but dynamically composed of four major modules:

| Cost Module | Percentage Range | Key Influencing Factors |

|---|---|---|

| Material Cost | 10% - 40% | Material type (plastic/metal/resin), unit price, amount used, and waste |

| Equipment & Processing Fee | 30% - 60% | Process choice, equipment depreciation, machining time, and complexity |

| Labor & Programming Fee | 10% - 25% | File preparation, programming difficulty, operator skill level |

| Post-processing Cost | 5% - 30% | Surface treatment (sanding, painting, plating, etc.), precision correction, special certifications |

Note: For overseas or remote projects, additional logistics, tariffs, and currency fluctuation costs should be considered (usually an extra 5%-15%).

2. In-Depth Cost Comparison and Selection Guide of Five Main Prototyping Technologies

Cost differences between various processes can reach dozens of times. Choosing the most suitable process is the first step in cost control.

1). FDM 3D Printing (Fused Deposition Modeling)

- Cost Range: Tens to hundreds of RMB (small and simple parts)

- Features: Uses ABS, PLA filament; lowest cost and relatively fast.

- Best For: Concept validation and low-precision appearance models. Suitable for extremely limited budgets or early-stage rough shape verification.

- Cost Traps: Rough surface finish; complex structures require supports; post-processing cleaning may add hidden labor costs.

2). SLA/DLP Photopolymerization 3D Printing

- Cost Range: Hundreds to thousands of RMB

- Features: Uses photosensitive resin; high precision (±0.05mm), smooth surface finish.

- Best For: High-precision, visually appealing display prototypes and complex structures (such as precision parts, medical models).

- Key Tip: Resin type affects price—high-temperature resistant or tough resins may cost 2-3 times more than standard resins.

3). CNC Machining

- Cost Range: Hundreds to thousands of RMB; complex metal parts may exceed tens of thousands.

- Features: Cuts from solid aluminum, steel, engineering plastics; excellent mechanical properties and highest precision (up to ±0.01mm).

- Best For: Functional testing prototypes, assembly validation, load-bearing parts. The gold standard for engineers verifying design reliability.

- Cost Logic: Material and machining time (programming, setup, processing) are the main costs. Simple small batch machining can significantly reduce unit cost.

4). Vacuum Casting (Silicone Molding)

- Cost Range: Mold cost (thousands of RMB) + unit cost (tens to hundreds RMB)

- Features: First create silicone molds, then cast materials like polyurethane for multiple copies. The cost-effective choice for small batches (10-100 pieces).

- Best For: Small batch pilot production, marketing samples, product launch event prototypes. Materials can mimic ABS, PP plastics, simulating final plastic properties.

5). Rapid Injection Molding (Soft/Aluminum Mold)

- Cost Range: Mold cost (thousands to tens of thousands RMB) + very low unit cost (a few to tens RMB)

- Features: Uses aluminum or simplified molds for small batch injection molding; material and process identical to mass production.

- Best For: Final validation before mass production and small batch production from hundreds to thousands of pieces. When quantity passes a threshold, unit cost is significantly lower than all other processes.

3. Five Key Factors Affecting Quotes & Negotiation Tips

When communicating with suppliers or evaluating quotes, pay close attention to these dimensions:

- Design & Complexity: The more complex the geometry and larger the size, the cost rises exponentially. Optimize design and simplify non-critical features.

- Precision & Tolerance: Pursuing extreme precision (e.g., ±0.01mm) will greatly increase machining time and process requirements, possibly increasing cost by 50%-200%. Clarify the truly required precision range.

- Material Selection: Compare cost-effectiveness while meeting performance requirements. For example, substituting 6061 aluminum for 7075, or ABS for PC, can save substantial costs.

- Post-processing Requirements: Clarify if each post-processing step (sandblasting, painting, silk-screening, etc.) is necessary. Limit advanced finishing to visible or critical areas only.

- Order Quantity & Lead Time: Batch size is the most effective lever to reduce costs. Avoid unnecessary rush orders; normal lead times can save up to 30% of expenses.

4. Why is Rapid Prototyping a Worthwhile Investment?

Despite upfront expenses, the value brought by rapid prototyping far exceeds its cost:

- Shortens Development Cycle: Enables rapid iteration and early detection of design flaws months ahead.

- Reduces Massive Risks: Prevents costly mold scrapping or production line shutdowns caused by design errors.

- Improves Communication Efficiency: Physical samples are more intuitive than drawings, ensuring alignment among teams, clients, and suppliers.

- Saves Overall Costs: Solves problems early in development at low cost, avoiding recalls or modifications after mass production.

5. Practical Cost-Saving and Optimization Strategies

- Design for Manufacturability (DFM) from the Start: Communicate early with prototyping engineers to optimize wall thickness, chamfers, and reduce unnecessary overhangs.

- Combine Processes: Use FDM/SLA for rapid shape validation of main parts, CNC machining for critical functional areas, then assemble.

- Leverage Batch Effects: Combine multiple parts from the same project for printing or machining; merge similar parts from different projects to share setup costs.

- Choose Suppliers Wisely: Select experienced, versatile providers who can suggest optimal processes and reduce trial-and-error and rework costs. Providing clear 3D files (e.g., STEP format) and clear requirements is essential for fast and accurate quoting.

Make an Informed Rapid Prototyping Investment Decision

| Your Needs | Recommended Process | Core Cost Optimization Approach |

|---|---|---|

| 1-5 pieces, concept validation, extremely low budget | FDM 3D Printing | Use basic materials, avoid unnecessary post-processing |

| 1-10 pieces, high-precision appearance/display parts | SLA 3D Printing or CNC Plastic Machining | SLA with standard resin; CNC with nesting optimization |

| 1-20 pieces, strict functional and assembly testing | CNC Machining (metal/plastic) | Optimize design to reduce machining time, consider batch setups |

| 10-100 pieces, small batch pilot production and samples | Vacuum Casting | Use standard silicone molds, plan production batches |

| Over 100 pieces, final validation before mass production | Rapid Injection Molding | Increase quantity to significantly lower unit cost |

Want the most accurate and competitive quote? The most effective way is to prepare your 3D design files and clearly specify the prototype’s purpose, quantity, material preferences, and expected delivery time, then consult a professional rapid prototyping service provider such as Rapid Model.