Metal 3D printing—also known as metal additive manufacturing—has become one of the most discussed fabrication technologies today. Compared with CNC machining, it eliminates significant material waste and enables complex designs that are impossible or highly expensive to produce using subtractive methods. However, many engineers and buyers still ask a key question: “How much does it really cost to 3D print a metal part?”

This article provides a complete, structured analysis of metal 3D printing cost drivers and offers a clear framework to help you estimate your project budget accurately.

1. Cost Range of Metal 3D Printing

The cost of a metal 3D printed part varies widely—from $50 to over $10,000. The huge price spread stems from the inherent characteristic of additive manufacturing: complexity is nearly free.

Lower Cost Range (Tens to Hundreds of USD)

Suitable for small, simple prototypes, fixtures, testing samples, or low-complexity functional parts.

Higher Cost Range (Thousands to Tens of Thousands of USD)

Common in highly complex, large components made from high-performance alloys, including aerospace turbine components or customized medical implants.

Compared with CNC machining, metal additive manufacturing does not aim to be “cheap.” Instead, its advantages include:

- No tooling cost: Ideal for low-volume or customized production that avoids expensive mold development.

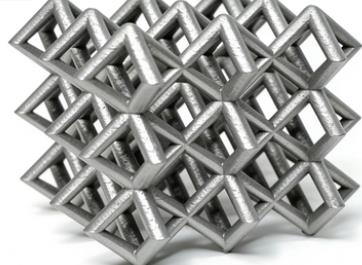

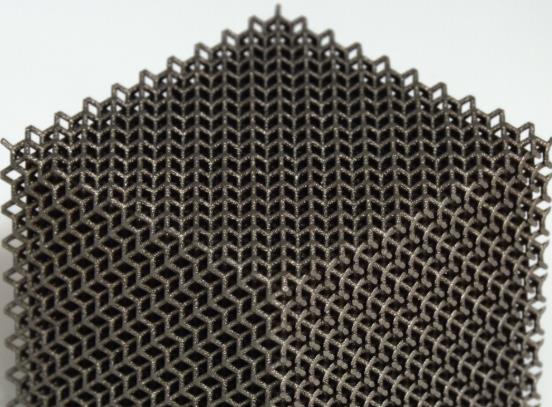

- Design freedom: Complex lightweight structures, conformal cooling channels, or integrated assemblies do not increase cost exponentially.

- High-performance materials: Enables direct forming of titanium alloys, nickel-based superalloys, and other materials that are difficult or expensive to machine.

2. Detailed Breakdown of Metal 3D Printing Costs

1) Material Cost: Metal Powder as the Primary Variable

Material selection significantly influences the final cost.

- Economical materials: Stainless steel and aluminum powders, typically $50–$120/kg.

- High-performance materials: Titanium alloy (Ti6Al4V), cobalt-chrome, and nickel superalloys such as Inconel, often $300–$600/kg or higher.

The actual cost also depends on powder utilization, recycling cycles, and potential losses from supports or powder degradation.

2) Printing Time and Machine Depreciation

Printing time is one of the most significant cost drivers.

- Industrial metal 3D printers (SLM/DMLS) typically cost $200,000–$1,000,000+.

- Depreciation, maintenance, calibration, inert gas supply, and facility operations are all included in the hourly rate.

- Many service providers charge by machine hours or build volume.

Parts with larger volumes, complex laser scanning paths, or intricate lattice structures require substantially more time, increasing the overall price.

3) Post-Processing: The “Hidden Cost” Often Overlooked

The part removed from the build plate is only a near-net-shape blank. Post-processing is essential and can sometimes exceed the printing cost.

Mandatory steps include:

- Support removal

- Stress-relief heat treatment

- Wire EDM to separate the part from the build plate

High-performance applications may require:

- Hot isostatic pressing (HIP) for improved density

- CNC machining to achieve tight tolerances

- Surface treatments such as blasting or electropolishing

- Nondestructive testing (X-ray, CT scanning)

4) Design Complexity and Optimization

Part geometry directly affects every cost element.

Poor design choices may result in:

- Excessive support structures

- Longer build times

- Hard-to-remove internal supports

- More extensive post-processing

Optimized designs can:

- Reduce material consumption

- Shorten printing time

- Improve mechanical performance

5) Order Volume and Supply Chain Strategy

Metal AM excels at low-volume (1–100 units) and customized production. For mass production (thousands of units), processes such as MIM or investment casting remain more cost-effective.

Most companies minimize cost and risk by outsourcing to experienced metal AM service providers rather than purchasing equipment in-house.

3. When Should You Choose Metal 3D Printing? A Comparison with CNC Machining

| Decision Criteria | Best Fit for Metal 3D Printing | Best Fit for CNC Machining |

|---|---|---|

| Geometric Complexity | Internal channels, conformal cooling, lattice structures, integrated designs | Simpler geometries, accessible surfaces |

| Order Volume | Low volume (<100 units), rapid validation | Medium to high volume (>500 units) |

| Material Characteristics | High-performance, hard-to-machine alloys | Common metals such as aluminum, steel, brass |

| Lead Time | No tooling required, complex parts produced quickly | Fast per-piece machining; ideal for stable mass production |

| Core Value | Lightweighting, performance optimization, functional integration | High precision, excellent surface finish, low cost at scale |

The industry is also adopting hybrid manufacturing—3D printing for near-net-shape + CNC machining for critical surfaces—to achieve optimal balance between precision and efficiency.

4. How to Effectively Control Metal 3D Printing Costs

- Design for Additive Manufacturing (DfAM): Use topology optimization and simulation tools to minimize volume while preserving performance.

- Smart orientation and support optimization: Reduce support volume, shorten build time, and simplify post-processing.

- Nesting and batch consolidation: Print multiple parts within the same build to lower per-part cost.

- Material selection: Choose cost-effective metals where performance allows (e.g., maraging steel instead of certain cobalt-chrome alloys).

- Define realistic tolerances: Avoid over-specifying tolerances on non-critical features to reduce machining costs.

- Partner with experienced service providers: Their engineering expertise, validated parameters, and post-processing capabilities significantly reduce risk and overall cost.

Get an Accurate Metal 3D Printing Quote

This article outlines the general pricing framework for metal additive manufacturing. Actual cost depends on part size, complexity, material grade, and precision requirements.

To obtain a precise quote, you may upload your CAD file and project specifications through our contact form. We will provide a detailed manufacturing assessment and quotation within 24 hours.