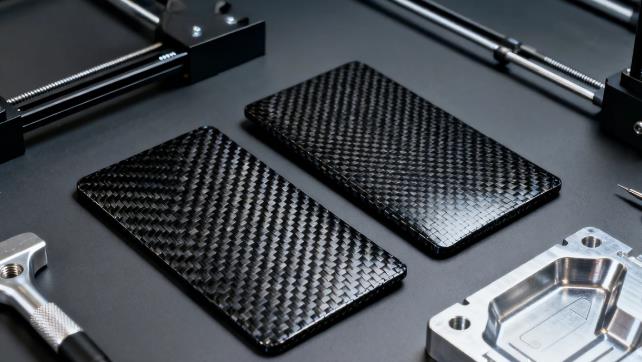

Carbon fiber reinforced polymer (CFRP) has an excellent strength-to-weight ratio and durability. It is becoming a core material in modern high-end manufacturing and prototype development. From racing car chassis to drone bodies, from precision instruments to consumer electronics, carbon fiber is driving innovation across many industries with its performance advantages.

1. What Is Carbon Fiber

Carbon fiber is an inorganic polymer fiber material with a carbon content of more than 90%. It is made from PAN, pitch, or viscose fibers through high-temperature treatment steps such as “pre-oxidation → carbonization → graphitization” at 2000–3000℃. Its microstructure is a graphite-like crystal arranged in a fibrous form. The fiber diameter is usually 5–10 μm, the single-filament strength can reach 3–7 GPa (about 10 times stronger than steel), and the density is only 1.7–1.8 g/cm³ (less than one-quarter of steel).

2. Processes and Workflow of Carbon Fiber Prototype Manufacturing

Carbon fiber prototype manufacturing is a multi-step, precise process. The goal is to produce trial parts that meet performance and accuracy requirements within a controlled cost and time frame.

The general workflow includes:

- Design and planning: Create 3D models with CAD software and consider fiber direction, lay-up design, and structural strength.

- Mold making: Produce molds based on the model. Materials can be aluminum, composite materials, or high-precision 3D printed resin. The mold surface must be smooth and coated with release agent.

- Lay-up and resin application: Place carbon fiber fabrics into the mold and combine them with resin using different processes.

- Curing and forming: Cure the resin by room temperature, heating, or autoclave (pressure vessel) to achieve cross-linking and hardening.

- Post-processing: After demolding, trim, CNC machine, sand, and finish the part to achieve the final dimensions and appearance.

Main Prototype Processes

| Process | Main Features | Advantages | Disadvantages | Typical Applications |

|---|---|---|---|---|

| Wet lay-up | Manual lay-up with resin brushing | Low cost, simple operation, low mold requirements | Uneven resin content, risk of bubbles, moderate strength and appearance | One-off prototypes, large or low-complexity parts |

| Vacuum bagging | Vacuum pressure applied on wet lay-up | Fewer bubbles, higher fiber content, better bonding | Need vacuum system, more complex process | Higher-quality structural prototypes |

| Prepreg lay-up | Pre-impregnated fiber cloth cured with heat and pressure | Accurate resin content, high strength, light weight, excellent surface | Materials need cold storage, require autoclave, higher cost | Aerospace, high-performance automotive parts |

| RTM / VaRTM | Inject resin into closed mold with dry fibers | Smooth two-sided finish, stable quality, suitable for small batch production | High mold cost, strict process control | Small to medium batch parts with high surface requirements |

| Carbon fiber 3D printing | Use chopped or continuous fiber filament | No mold needed, high design freedom, fast iteration | Strength lower than traditional lay-up, surface needs finishing | Complex shapes, rapid concept verification |

3. Key Application Areas

Automotive and Motorsports

Carbon fiber is used for monocoque chassis, body panels, suspension parts, and braking systems. It reduces weight and improves acceleration, handling, and energy efficiency. For electric vehicles, lightweight materials directly increase driving range and reduce range anxiety.

Aerospace and Defense

From commercial aircraft like Boeing 787 and Airbus A350 to drones and satellite structures, carbon fiber reduces weight while increasing fuel efficiency and load capacity. Its fatigue resistance and corrosion resistance ensure long-term reliability.

High-end Electronics and Sports Equipment

Carbon fiber has both a high-tech look and strong performance. It is used in laptops, drone frames, bicycle frames, tennis rackets, and more, providing lightweight, stiffness, and vibration damping.

4. Manufacturing Challenges and Process Selection

Anisotropy of material: Fiber direction determines mechanical properties, so lay-up design must be accurately simulated and verified.

High cost: Raw materials are expensive and high-end equipment (such as autoclaves) is costly.

Machining difficulty: Carbon fiber is hard and abrasive. CNC machining may cause tool wear, delamination, or burrs. Diamond-coated tools and optimized cutting parameters are needed.

High process control: Resin viscosity, curing temperature, and pressure distribution all affect final quality. Strict monitoring is required.

Process Selection Considerations

- Strength and accuracy needs: Prepreg + autoclave gives the highest performance; RTM is suitable for medium-strength parts with smooth surfaces.

- Budget and lead time: Wet lay-up and 3D printing are low cost and fast; prepreg and RTM fit small-batch final parts.

- Production volume: For single or very small batches, use 3D printing or wet lay-up. For dozens to hundreds, consider RTM. For mass production, steel molds and automation are needed.

5. Role of Carbon Fiber in Rapid Prototyping

- Faster design iteration: 3D printing can produce complex functional prototypes in hours, enabling quick testing and improvement.

- Functional and performance testing: Carbon fiber prototypes made through additive manufacturing or rapid mold processes can undergo mechanical, thermal, and environmental tests, reducing development risk.

- Cost-effective small batch production: For up to several hundred pieces, 3D printing or soft-tool RTM offers better economics and shorter delivery than traditional hard tooling.

- Digital manufacturing integration: Carbon fiber manufacturing is moving toward digital and smart production with CAE simulation, automated fiber placement, and online monitoring, improving consistency and reducing waste.

Contact Rapid Model

Rapid Model has extensive experience and can produce high-quality composite parts using prepreg carbon fiber and carbon fiber machining technologies. If you need support, please send your drawings and project details through our contact form. Our team will reply within 24 hours.