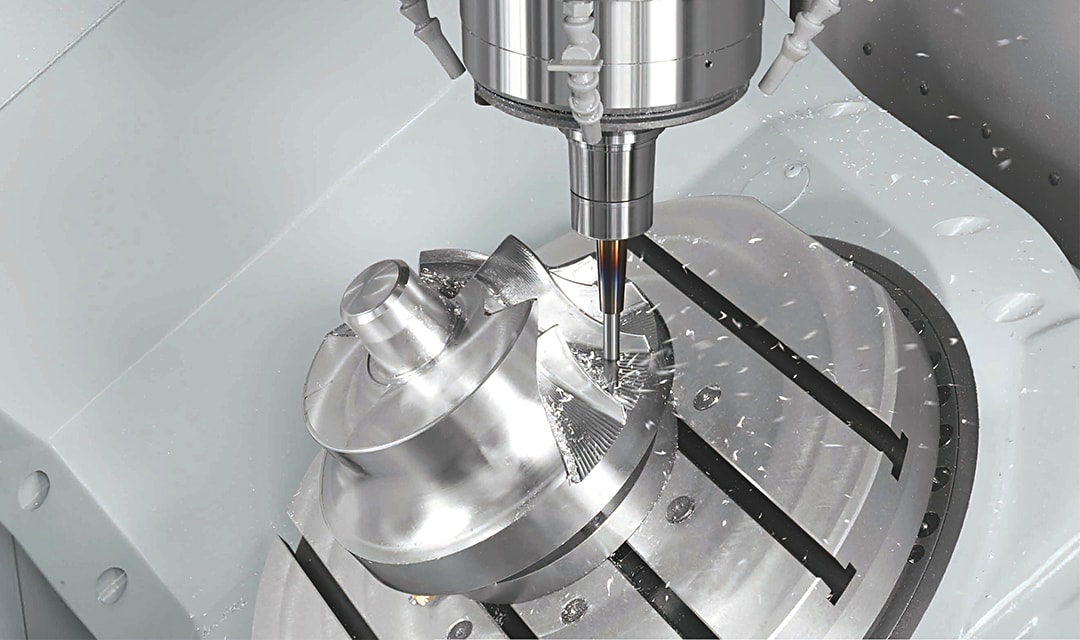

Rapid Model Factory

At Rapid Model, we are dedicated to providing high-quality CNC machining services to customers worldwide. We focus on enhancing our clients’ brand development and competitiveness, striving to meet their diverse needs through precise technology and efficient production processes. To facilitate communication, our sales team is proficient in multiple languages, including German, English, French, and Russian. We place great importance on establishing effective communication channels to ensure every client has full confidence in our work.

We respond to customer inquiries within 2 to 7 hours, including quotes and mold production schedules. We understand the unique requirements of each project and aim to provide the most suitable solutions in the shortest possible time. Additionally, we welcome every client to visit our factory at any time to learn about our production capabilities and processes, ensuring that you have a full understanding of our services and quality.