High-quality manufacturing services, tailored to your machining solutions.

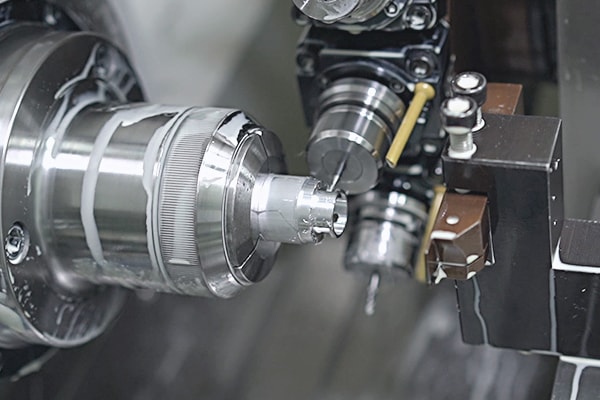

Our CNC turning se provide high-precision manufacturing capabilities for rotationally symmetrical parts. As part of our CNC machining, we specialize in processing shafts, hubs, and parts with complex geometries. The advanced CNC systems meet the needs from prototype design to mass production, ensuring dimensional accuracy and surface finish.

| Capability | Details/Specifications |

|---|---|

| Material Compatibility | Stainless Steel, Aluminum, Brass, Titanium, Engineering Plastics |

| Tolerance | ±0.005 inches (0.127 mm) or better |

| Max Machining Diameter | 30 inches (762 mm) |

| Max Machining Length | 60 inches (1526 mm) |

| Surface Finish | Ra ≥ 125 μin |

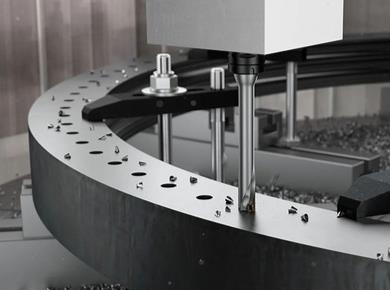

From rapid prototyping to mass production, our CNC milling services offer multi-axis machining capabilities. It is the ideal choice for manufacturing precision parts with complex 3D geometries. The Rapid Model machining center can handle over 50 materials while maintaining strict tolerance control and excellent surface quality.

| Capability | Details/Specifications |

|---|---|

| Material Compatibility | Tool Steel, Stainless Steel, Aluminum, Titanium, Composites |

| Tolerance | ±0.005 inches (0.127mm) |

| Working Range | X: 60 inches (1524mm), Y: 40 inches (1016mm), Z: 20 inches (508mm) |

| Surface Finish | Ra ≥ 125 μin |

| Multi-axis Capability | 3-axis, 4-axis, 5-axis machining |

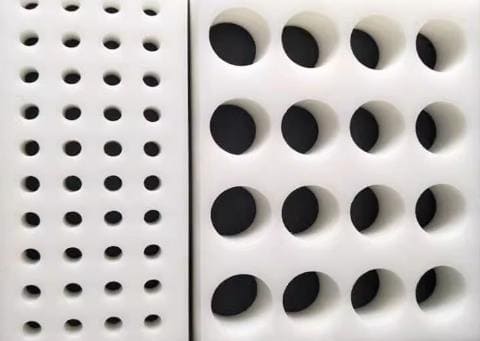

Mirror EDM (Electric Discharge Machining) is a high-precision machining technology used for complex shapes and fine surface treatments. This technique removes metal through electrical discharges, making it ideal for hard metals like steel, titanium, and aluminum alloys. We offer professional Mirror EDM services to ensure smooth, flawless surfaces, meeting the strict requirements of the aerospace, automotive, and electronics industries.

| Capability | Details/Specifications |

|---|---|

| Material Compatibility | Stainless Steel, Titanium, Aluminum, Tool Steel, Copper |

| Tolerance | ±0.001 inches (0.025 mm) or better |

| Max Working Dimensions | Length: 16 inches (400 mm) Width: 12 inches (300 mm) Height: 8 inches (200 mm) |

| Cutting Speed | Up to 300 mm²/min (depending on material and thickness) |

| Surface Finish | Fine up to Ra 0.4μm |

| Max Cutting Thickness | Max 12 inches (300 mm) |

| Wire Diameter Range | 0.004 inches (0.1 mm) to 0.012 inches (0.3 mm) |

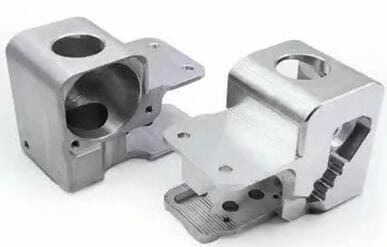

Our precision grinding services are specially tailored for critical components that require high dimensional accuracy and surface finish. Whether it's hardened materials, complex geometries, or parts with strict tolerance requirements, we always find precise and suitable solutions. These services are commonly applied in mold making, aerospace, and medical device industries.

| Capability | Details/Specifications |

|---|---|

| Material Compatibility | Hardened Steel, Ceramics, Tungsten Carbide, Stainless Steel, Titanium |

| Tolerance | ±0.0001 inches (0.0025 mm) |

| Grinding Types | Surface Grinding, Cylindrical Grinding, Internal Grinding, Centerless Grinding |

| Max Workpiece Size | Diameter: 15 inches (380 mm) Length: 40 inches (1016 mm) |

| Surface Finish | Ra 0.1μm to Ra 0.4μm |

| Roundness Accuracy | 0.0001 inches (0.0025 mm) |

| Category | 3-Axis CNC | 4-Axis CNC | 5-Axis CNC |

|---|---|---|---|

| Tolerances | ±0.05 ~ ±0.02 mm | ±0.05 ~ ±0.02 mm | ±0.05 ~ ±0.01 mm |

| Repeatability | ±0.02~±0.01 mm | ±0.02~±0.01mm | ±0.008~±0.005 mm |

| Machinable Surfaces | Single setup, XYZ only | Added rotation axis for angled features | Full-surface multi-axis machining |

| Typical Applications | Flat parts, outer contours | Angled holes, curves, engraving | Complex surfaces, high-precision molds |

Precise and efficient 3-5 axis CNC machining to meet the demands of complex and Precision CNC parts manufacturing.

Our Precision 3 axis CNC mills provide high precision for components with prismatic features, typically achieving tolerances of ±0.05mm, with capability down to ±0.02mm for select applications

Applications: Brackets, plates, fixtures, and basic housings.

Our 4 axis CNC lathes are equipped with live tooling, enabling efficient machining of complex rotational parts. Most intricate features can be completed in a single setup without the need for secondary operations, significantly improving both precision and efficiency.

Applications: Shafts, couplings, valves, and rotational components.

Our advanced 5-axis machining centers can complete complex multi-surface machining in a single setup. The machining tolerance is typically ±0.05 mm, and for certain precision applications, it can be as tight as ±0.01 mm.

Applications: Turbine blades, impellers, aerospace components, and medical implants.

Rapid Model has been continuously earning customer recognition through dedication and quality

Our factory responds quickly to customer needs, providing high-quality precision machining services.

We are capable of machining more than 50 types of materials. Rapid prototyping orders can be delivered in as fast as 3 days, while small- and large-batch productions are typically completed within 1–2 weeks. Customers can choose from nine surface finishing options.

The factory is certified with ISO 9001 and other quality management systems, demonstrating our full capability to deliver products that meet strict quality standards.

Get an Online CNC Quote

We are capable of machining a wide variety of materials, with a particular expertise in metal machining.

Aluminum, Stainless Steel, Titanium, Brass, Copper, Tool Steel, Inconel, Hastelloy, Magnesium, Bronze

PEEK, Delrin, Nylon, PTFE, Acrylic, PVC, Polycarbonate, Ultem, HDPE, POM

Carbon Fiber, G10/FR4, Fiberglass, Phenolic, Ceramic-filled Polymers

Notice: the processing of plastics and composite materials involves dedicated tools and processes to ensure structural integrity and dimensional accuracy.

Rapid Model provide nine types of surface treatment methods.

Characteristics: High-speed abrasive particles are blasted onto the surface to remove rust, oxide layers, old coatings, and contaminants.

Characteristics: Mechanical friction removes surface irregularities, resulting in a smooth and shiny finish.

Characteristics: Removal of burrs, sharp edges, or flash generated during machining.

Characteristics: Electrochemical process that forms an oxide layer on aluminum or aluminum alloys.

Characteristics: Deposition of a metal layer such as nickel, chromium, or zinc on the surface through electrolysis.

Characteristics: Use of chemical solutions to perform passivation, degreasing, phosphating, etc., on metal surfaces.

Characteristics: Application of protective or decorative layers by spraying, dipping, brushing, etc.

Characteristics: Physical or chemical methods to increase surface hardness of materials.

Characteristics: Heating, holding, and cooling processes to alter the internal structure of metals.

Learn about precision CNC machining to better understand the related knowledge and master essential industry skills.

Precision machining refers to the process of removing material from a workpiece using high-accuracy CNC machines to achieve tight tolerances and superior surface finishes.

It is essential for manufacturing parts that require exact dimensions, smooth surfaces, and reliable performance — commonly used in aerospace, medical, automotive, and electronics industries.

Typical tolerances can reach ±0.01 mm or tighter, with surface roughness up to Ra 0.4 μm.

The advantages of precision machining lie in its high accuracy, efficiency, and consistency. It can produce complex parts within tight tolerance ranges, ensuring excellent surface finish and assembly precision. Suitable for materials such as aluminum, stainless steel, and titanium alloys, it meets the needs from prototyping to mass production, significantly enhancing product performance, reducing manufacturing costs, and ensuring stable quality.

Customizable and flexible low-volume precision CNC machining solutions, available on a first-come, first-served basis.

Our low-volume CNC machining is fast and efficient, with a minimum order of 60 pieces. However, we can reduce the order quantity based on customer needs. We complete production quickly, often within a single day, and offer expedited services with air shipping to ensure your project stays on track, even under tight deadlines. For non-urgent orders, sea and land shipping options are available.

Simply upload your drawings or send us your samples, and our engineering team will develop a tailored solution that meets your requirements while optimizing costs. If you don't have a design ready, our engineers can assist you in creating one and provide a complete CNC machining solution to meet your needs.

One of our strengths is our ability to deliver quickly, with some orders completed in as little as two days. This is made possible by our strong logistics network and efficient customs processes. We offer a variety of customizable CNC machining services to meet your specific requirements.

Priority is given to protecting your parts throughout the entire transportation process, ensuring efficient logistics, reliable transportation, and sturdy packaging.

At Rapid Model, we prioritize fast and reliable logistics to ensure the global delivery of CNC precision parts. Our efficient logistics network guarantees timely shipments to meet tight deadlines, whether it's expedited air freight or standard sea freight.

We provide dependable transportation solutions for all CNC machining components, including temperature-sensitive or fragile items. From door-to-door services to specific customs handling, we maintain seamless control over every step of the shipping process.

We use high-quality packaging that meets industry standards to protect your CNC precision parts during transit. Our custom packaging solutions are designed to prevent damage from vibrations, impacts, and environmental factors.

Get an Online CNC Quote

A systematic approach to precision manufacturing

Our engineering team reviews your design for manufacturability, suggesting optimizations for cost, performance, and production efficiency.

Using advanced CAM software, we create optimized toolpaths and select appropriate tooling, fixtures, and machining strategies for your project.

Components are manufactured on our state-of-the-art CNC machines by skilled machinists who monitor the process to ensure quality and precision.

Every part undergoes rigorous inspection using CMMs, optical comparators, and surface testers to verify compliance with specifications.

Providing precision components for demanding applications

Flight-critical components, engine parts, landing gear components, and defense system parts manufactured to aerospace standards.

Precision surgical instruments, implantable devices, diagnostic equipment components, and medical device prototypes.

High-performance engine components, transmission parts, suspension elements, and custom racing components.

While ensuring exceptional quality, we offer factory-direct pricing. Contact us now to meet your precision machining needs.

Get a Free Quote