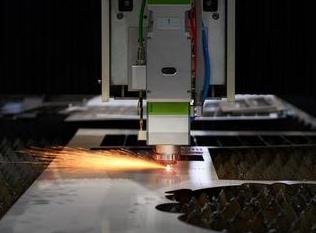

Laser cutting offers advantages such as high precision and efficiency, making it especially suitable for projects requiring high accuracy, complex shapes, and high production efficiency.

Its fine cutting and high-quality processing make it the preferred technology in industries like aerospace, automotive, electronics, and medical devices.

Choosing laser cutting ensures the quality of the final product and reduces the cost of secondary processing.

Online Quote