Inspection Equipment

CMM, Optical Comparators, Surface Testers, Hardness Testers

Certifications

ISO 9001:2015, AS9100, ITAR Registered

Documentation

Full inspection reports, material certs, first article reports

Read MoreRapid-Model has over 15 years of precision machining experience, making us a trusted partner in the CNC turning services industry.

Customize CNC turning parts online: upload your drawings and share your requirements. We start production within 1 hour and provide real-time video updates of the manufacturing process.

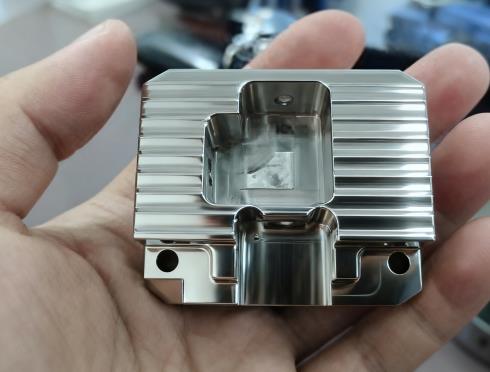

Our advanced CNC turning centers can handle complex geometries and special materials with tolerances up to ±0.005mm, producing precision components for aerospace, automotive, medical, and industrial applications.

CNC Turning Quote

We offer comprehensive CNC turning solutions tailored to meet your specific requirements.

Our CNC lathes can machine the external surfaces of cylindrical parts with high precision. We are able to achieve tight tolerances and excellent surface finishes.

We provide precision internal turning and boring services for holes, cavities, and bores, ensuring concentricity and smooth surfaces.

We offer taper turning for both internal and external conical features, with precise angles and smooth surfaces, suitable for shafts, fittings, and specialized components.

From prototyping to mass production, Rapid Model turns your ideas into reality. Click below to contact us.

Our CNC prototyping service can quickly help you validate your prototype’s functionality, and provide manufacturability feedback — helping you turn your idea into reality. Typically, our CNC turning capacity covers parts up to ≤ 1000 mm, with a tolerance of ±0.05 mm. For high-precision turning, we can achieve tolerances of ±0.01 mm to ±0.005 mm.

CNC Turning QuoteWe offer small-batch CNC turning services with a stable two-week delivery lead time, and we also provide large-volume production. Our turning accuracy can be controlled to ±0.008 mm, and machining repeatability can be held steadily at ±0.005 mm. We are your stable and reliable manufacturing partner for your brand.

CNC Turning QuoteWe are committed to delivering CNC turning parts with consistent high quality, perfectly meeting each customer’s specifications.

We provide comprehensive customer support along with real-time production video, allowing you to monitor your CNC turning parts at any stage. Our dedicated account managers stay in close communication and make every effort to resolve any issues you may encounter.

We support prototyping, low-volume, and large-volume production while maintaining product quality and fast delivery. Prototyping orders can start from as few as 1–10 pieces, ensuring flexibility for your project needs.

For urgent requirements or tight deadlines, we take rapid action and coordinate with logistics to plan the fastest air shipment routes, saving you valuable time and ensuring your CNC turning parts arrive on schedule.

Our commitment to quality ensures that every CNC turned part meets your exact specifications.

CMM, Optical Comparators, Surface Testers, Hardness Testers

ISO 9001:2015, AS9100, ITAR Registered

Full inspection reports, material certs, first article reports

Read More

From concept to delivery, we make CNC turning simple and efficient.

Submit your CAD files and requirements

Our engineers optimize for manufacturability

Precision machining with quality checks

Comprehensive inspection and reporting

Fast shipping to your location

We work with a wide range of materials to meet your specific application requirements.

Common Types:6061, 7075, 5052, 2024, 1100, 6082.

Features:Lightweight, strong, corrosion-resistant, easy to machine. 6061 and 7075 are popular in aerospace and automotive industries.

Uses:Auto parts, aerospace structures, enclosures, radiators.

Common Types:304, 316, 420, 430

Features:Excellent corrosion resistance, high strength, but harder to machine. 304 is used in food and medical industries, while 316 is preferred for harsh environments.

Uses:Medical equipment, food processing, chemical pipes, auto parts.

Common Types:1018, 1045, 12L14.

Features:Strong, hard, but prone to corrosion. Surface treatments can improve corrosion resistance.

Uses:Medical equipment, food processing, chemical pipes, auto parts.

Common Types:C360, C464, C954

Features:Wear-resistant, corrosion-resistant, good for high-load applications.

Uses:Bearings, gears, valves, electronic components.

Common Types:Titanium Alloys, Bronze

Features:Bronze, Wear-resistant, corrosion-resistant, good for high-load applications.

Uses:Bearings, gears, valves, electronic components.

Common Types:ABS, Polycarbonate (PC), Nylon, PTFE, Polypropylene (PP).

Features:Lightweight, cost-effective, easy to machine. Different plastics have varying mechanical properties, heat resistance, and chemical resistance.

Uses:Electronics enclosures, auto parts, medical devices, furniture components.

Customize aluminum and stainless steel turned parts with Rapid Model, and enjoy premium after-sales service

Our CNC turning aluminum parts service provides lightweight, durable, and cost-effective solutions for rapid prototyping and production. With strict tolerance control and excellent surface finish, our aluminum components are ideal for aerospace, automotive, and electronics applications. Fast delivery and consistent quality ensure your projects proceed smoothly without delays.

Read More

Our CNC turning centers can handle complex geometries with tolerances maintained within ±0.005mm. Every stainless steel part undergoes rigorous quality inspection, guaranteeing durability and consistent precision. Upload your CAD drawings online to receive your custom stainless steel CNC turning parts.

CNC Turning QuoteOur precision CNC turning services support diverse industries with specialized requirements.

High wear resistance, long service life, suitable for both mass production and single-piece customization.

Durable, precision parts for performance and production vehicles.

Biocompatible materials with exceptional surface finishes and tolerances.

Trusted by industry leaders for precision CNC turning services.

Find answers to common questions about our CNC turning services.

We accommodate orders of all sizes. For prototypes, we accept single piece orders. For production runs, our minimum is typically 60 pieces, but we can discuss smaller quantities based on your requirements.

Request a Quote NowRapid Model is your leading CNC turning company, consistently providing highly reliable CNC turning services to multiple industries.

Our commitment and improved technical approach help us provide complex prototypes and production parts that meet your needs.