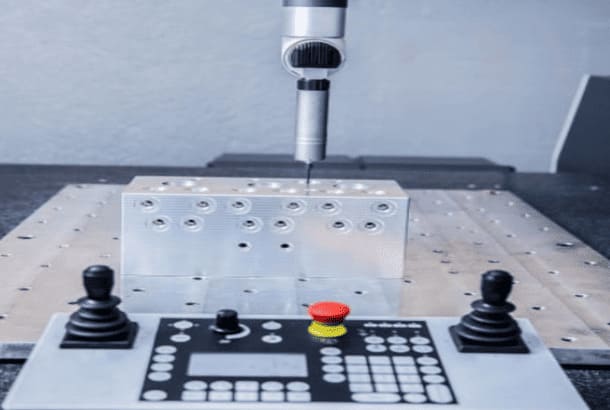

precision hole machining services

We provide precision hole machining services, covering various processes such as drilling, tapping, boring, and reaming, to meet the machining requirements of all types of CNC parts.

With our advanced CNC machining centers, we are capable of achieving high-precision hole positioning, deep threads, and excellent surface finishes, ensuring that every hole meets the strict standards for assembly and performance.

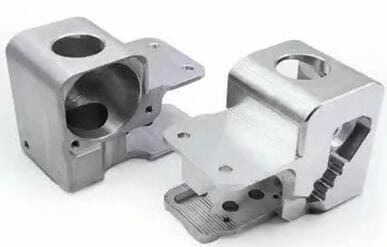

Multi-Axis CNC Machining Services

We provide multi-axis CNC machining services, covering 3-axis, 4-axis, and 5-axis machining centers, capable of efficiently handling complex 3D contours and multi-faceted parts. Through multi-axis simultaneous machining, we reduce setup times while improving machining accuracy and surface finish. Whether for prototype development or mass production, we offer customized solutions to meet the diverse needs of our clients.