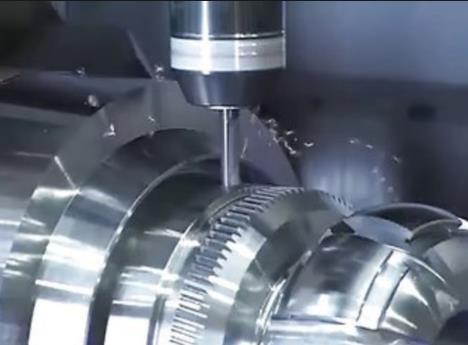

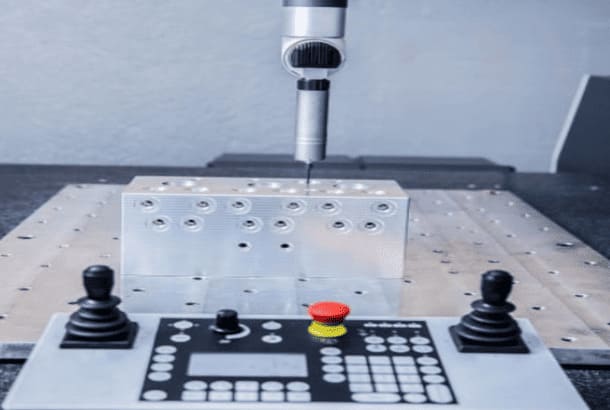

Aluminum is a versatile, lightweight metal favored in CNC machining for its excellent machinability,

strength-to-weight ratio, and corrosion resistance. It provides high precision and smooth finishes,

ideal for intricate components in automotive, aerospace, and electronics.

Surface Treatment

Anodizing, electroplating, powder coating

Build Time

3 to 5 Business Days

Services

CNC Milling, CNC Turning

Subtypes

Aluminum 6061, Aluminum 7075, Aluminum 5052, Aluminum 2024, Aluminum 6063

Tensile Strength

70-700 MPa (depending on alloy)

Copper is known for its excellent electrical and thermal conductivity. It is often used in electrical components,

heat exchangers, and various industrial applications. Copper offers good machinability and corrosion resistance.

Surface Treatment

Electroplating, polishing, patination

Build Time

4 to 6 Business Days

Electrical Conductivity

100% IACS (International Annealed Copper Standard)

Thermal Conductivity

401 W/(m·K)

Common Applications

Electrical wiring, heat exchangers, roofing, plumbing

Bronze is an alloy consisting primarily of copper, commonly with about 12-12.5% tin and often with the addition of other metals

and sometimes non-metals. It is known for its hardness, durability, and resistance to corrosion.

Surface Treatment

Polishing, lacquering, patination

Build Time

5 to 7 Business Days

Common Alloys

Phosphor bronze, aluminum bronze, silicon bronze

Typical Applications

Bushings, bearings, marine hardware, sculptures

Steel is an alloy of iron and carbon, and sometimes other elements. Because of its high tensile strength and low cost,

it is a major component used in buildings, infrastructure, tools, ships, machines, appliances, and weapons.

Surface Treatment

Galvanizing, painting, powder coating, plating

Build Time

4 to 6 Business Days

Carbon Content

0.05% to 2.1% by weight

Tensile Strength

400-2500 MPa (depending on grade and treatment)

Alloy steel is steel that is alloyed with a variety of elements in total amounts between 1.0% and 50% by weight to improve its mechanical properties.

Common alloying elements include manganese, nickel, chromium, molybdenum, vanadium, silicon, and boron.

Surface Treatment

Case hardening, nitriding, chrome plating

Price Range

$$$ (Medium to High)

Build Time

5 to 8 Business Days

Common Alloying Elements

Manganese, nickel, chromium, molybdenum, vanadium

Applications

Gears, shafts, connecting rods, machinery parts

Stainless steel is known for its excellent corrosion resistance and strength. It is widely used in medical devices,

food processing equipment, marine applications, and architectural components due to its durability and aesthetic appeal.

Surface Treatment

Polishing, passivation, brushing, electroplating

Price Range

$$$$$ (Premium)

Build Time

5 to 8 Business Days

Chromium Content

Minimum 10.5%

Common Grades

304, 316, 430, 410, 17-4 PH

Magnesium is the lightest structural metal, offering an excellent strength-to-weight ratio.

It has good machinability and damping capacity, making it suitable for applications where weight reduction is critical.

Surface Treatment

Anodizing, coating, plating

Density

1.74 g/cm³ (lightest structural metal)

Common Applications

Aerospace components, automotive parts, electronics housings

Brass is a copper-zinc alloy known for its excellent machinability, corrosion resistance,

and attractive golden appearance. It is commonly used in fittings, valves, gears, and

decorative parts, making it a versatile material for both functional and aesthetic applications.

Surface Treatment

Polishing, Plating, Sandblasting

Build Time

3 to 5 Business Days

Services

CNC Milling, CNC Turning

Subtypes

C260 (Cartridge Brass), C360 (Free-Cutting Brass)

Tensile Strength

250–500 MPa (depending on grade)