Custom CNC Milling Services | Multi-axis CNC milling

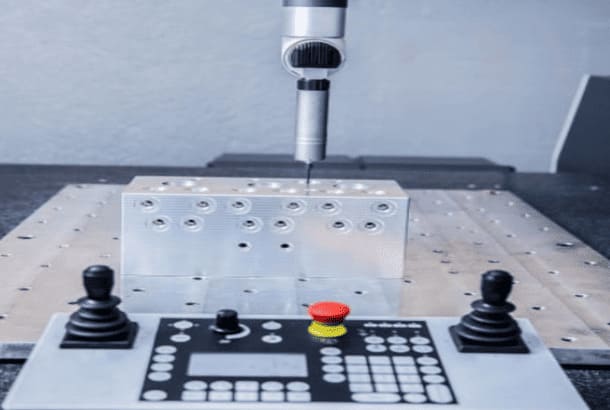

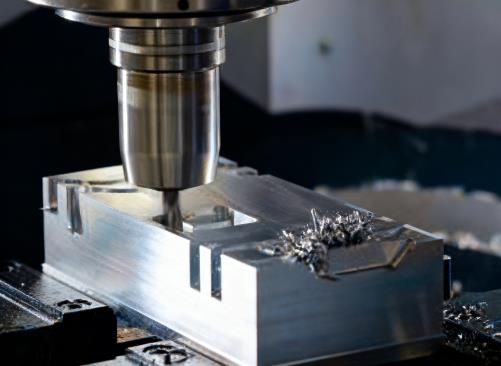

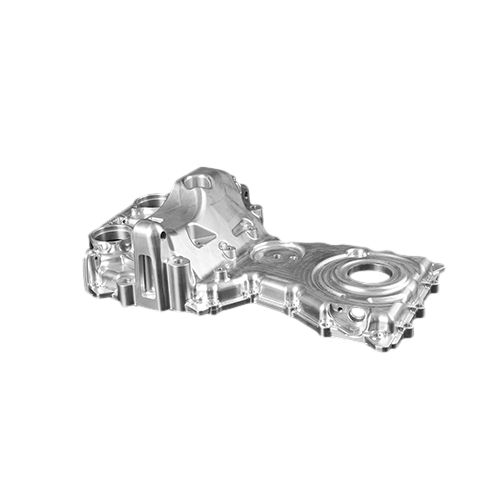

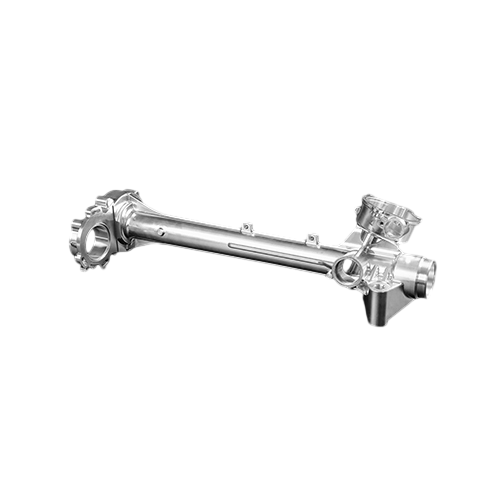

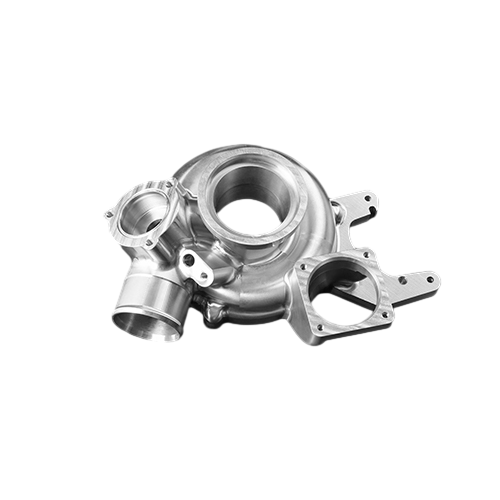

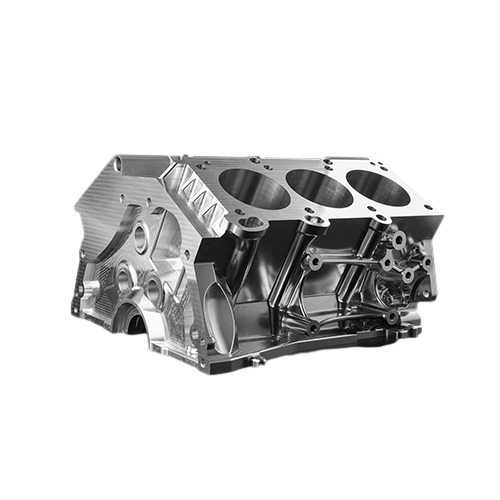

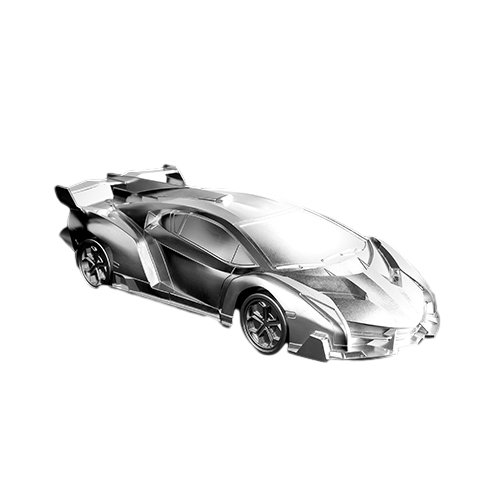

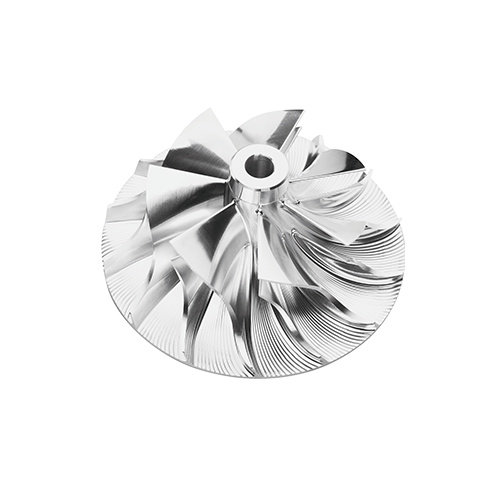

Rapid Model offers custom CNC milling services with tight tolerances controlled within ±0.01 mm. Our machining capabilities cover a variety of materials, including aluminum CNC milling, steel CNC milling, and engineering plastics. With multiple 3-axis, 4-axis, and 5-axis CNC milling machines, we provide both custom CNC milling for prototypes and small-batch production starting from 60 pieces, while also supporting large-scale industrial production.

One-stop CNC milling solutions

CNC milled parts – Prototyping with delivery in as fast as 3 days.

Repeatability:±0.005mm~±0.008 mm