CNC turning machine tools are among the most commonly used equipment in industrial enterprises. They are characterized by wide applicability, simple structure, easy operation, and easy maintenance. These machines are used for turning operations on rotating parts such as shafts, disks, and other components, including turning of the outer diameter, end faces, center holes, and threads. In terms of structural layout, the most commonly used CNC turning machine tools in industrial enterprises are horizontal CNC lathes and vertical CNC lathes, with horizontal CNC lathes being the most widely used.

Popular-type CNC Lathes

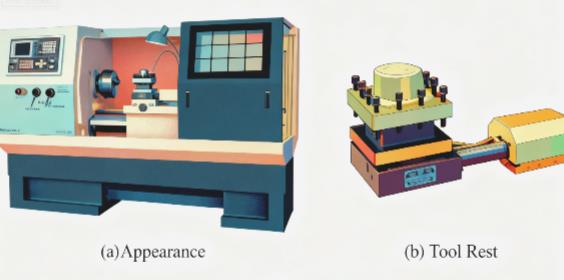

In China, popular-type CNC lathes are simplified CNC products evolved from conventional lathes. The main components, structure, appearance, and key technical parameters of these lathes are similar to those of conventional lathes. Small and medium-sized horizontal popular-type CNC lathes are shown in Figure 1. This type of machine tool is only a partial improvement over the conventional lathe to meet the CNC requirements, with the bed, headstock, tailstock, carriage, and auxiliary systems like hydraulics, cooling, lighting, and lubrication being quite similar to a conventional lathe.

Popular-type CNC lathes generally use frequency-controlled motors. Since the low-frequency output torque of the frequency converter is small, mechanical gears are still required to improve the low-speed torque of the spindle. However, the number of speed ranges can be fewer than on conventional lathes. The headstock structure is relatively simple. The machine tool is generally equipped with an electric turret instead of the manual turret found on conventional lathes, enhancing automation and tool-changing capabilities. These lathes are simple in structure, affordable, and easy to maintain. They are suitable for automatic processing of simple parts. However, since most of the CNC systems used are domestically made and have basic functions, these machines lack closed-loop position control, resulting in lower precision and processing efficiency compared to full-function CNC lathes. These machines are not suitable for high-speed or high-precision processing.

Full-function CNC Lathes

A full-function CNC lathe is a true CNC lathe that requires a fully functional imported CNC system and has closed-loop position control. It is capable of high-precision contour machining. Small and medium-sized horizontal full-function CNC lathes are shown in Figure 2. The structure and layout of full-function CNC lathes are generally designed according to the requirements of CNC machine tools. These machines typically adopt a slant-bed design with the automatic turret positioned at the rear of the bed, and the headstock is fixed on the bed.

The spindle drive of full-function CNC lathes uses an AC spindle drive system supplied by the CNC manufacturer, offering a wide speed range, high low-speed torque, and high maximum speed. Additionally, the spindle has functions like orientation and positioning. High-speed, high-precision CNC lathes often use advanced components such as high-speed spindle units and electric spindles, achieving significantly higher spindle speed and precision compared to popular-type CNC lathes.

Full-function CNC lathes generally use hydraulic turrets for automatic tool changing. The rigidity, tool capacity, indexing accuracy, and tool change speed of the turret are far superior to those of electric turrets. Full-function CNC lathes have the fundamental technical characteristics of high-speed, high-efficiency, and high-precision CNC machine tools. Their auxiliary systems are more advanced and complete than those of popular-type CNC lathes. The chuck, tailstock, and other components often use hydraulic automatic control. Additionally, the machine tool is equipped with a high-pressure, large-capacity automatic cooling system, automatic lubrication, and chip removal systems. As a result, these lathes typically require a fully enclosed safety guard.

Introduction to CNC Turning Centers

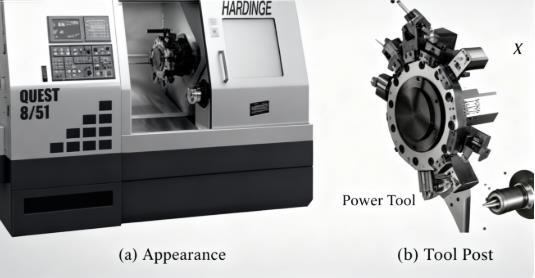

A turning center is developed based on a fully functional CNC lathe and is used for turning, milling, and hole processing on rotating parts. The turning center is one of the earliest types of CNC machines to combine both turning and milling functions, with the horizontal version being the most common. A typical turning center product, as shown in Figure 3, has a similar appearance to a fully functional CNC lathe but differs significantly in its internal structure and performance. The spindle has C-axis control, and the turret can be equipped with live tools for drilling, boring, and milling operations. The ability for the tools to move along the vertical Y-axis is the main difference between a turning center and a fully functional CNC lathe.

C-axis Control

C-axis control, also known as spindle interpolation or C-axis interpolation, is a function where the spindle rotates around the Z-axis. This movement axis is defined as the C-axis. Therefore, this function is referred to as C-axis contouring control.

In turning operations, the spindle drives the workpiece to rotate, while the tool moves along the feed direction (X and Z axes). However, in drilling, boring, and milling operations, the spindle drives the tool's rotation, while either the workpiece or the tool moves along the feed direction. The two processes have entirely different machining characteristics. Therefore, the spindle of the turning center must not only rotate the workpiece for turning but also be able to clamp and position the workpiece at any point for drilling, boring, and milling. Additionally, the spindle participates in interpolation calculations like the X, Y, and Z axes to achieve the feed motion and complete the cylindrical surface processing.

Live Tools

Live tools are special rotating tools used for machining. In conventional CNC lathes, the turning process is achieved by rotating the workpiece, as shown in Figure 4. The tools mounted on the turret do not (nor need to) rotate. However, in a turning center, to perform turning operations on the side faces and end faces of a rotating workpiece or to mill, drill, or bore, the turret must be equipped with live tools capable of these processes. These live tools are driven by the sub-spindle (second spindle) for rotation.

Y-axis Motion

For turning operations on the inner and outer diameters and end faces of a rotating workpiece, only axial (Z-axis) and radial (X-axis) feed motions are required. However, for side face, end face hole, and milling operations, in addition to axial and radial feed, vertical tool-axis motion is also necessary. Therefore, a turning center requires at least X, Y, and Z feed axes. The turret of a turning center is similar in appearance to the turret of a fully functional CNC lathe, but the internal structure and control requirements are significantly different. The turret of a CNC lathe only has indexing and positioning functions, while the turret of a turning center must not only have indexing and positioning but also a drive system for live tools, making its structure more complex.