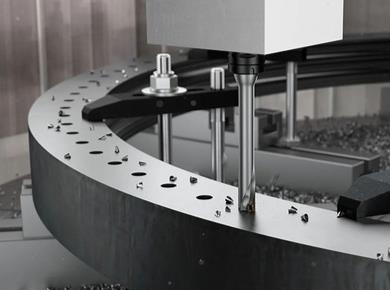

Have you ever encountered this? For CNC machining centers equipped with FANUC control, the spindle speed may show abnormal behavior during machining. The speed displayed on the system is unstable, fluctuating between fast and slow. Rapid Model, with 18 years of industry experience specializing in ultra-precision CNC machining, shares effective solutions today.

1. Pre-repair Preparation for CNC Machining Center Spindle

An abnormal spindle speed means that the spindle speed feedback from the CNC machining center doesn’t match the set speed (typically showing a lower speed than the set speed). In some cases, you may hear abnormal "squeaking" sounds during operation, or the spindle may speed up and slow down unexpectedly. Occasionally, an overcurrent alarm may also trigger on the motor. If the CNC machining center has an encoder feedback system, the speed displayed on the system monitor should match the set speed. Spindle transmission can use either belt drive or gear drive, with most modern machines using synchronous belt transmission. Abnormal speed may result from excessive belt length causing slippage, or there may be slippage in the synchronous belt connecting the spindle and encoder. Poor lubrication or damaged bearings can also cause resistance and affect smooth spindle rotation. External signal interference can lead to similar issues.

2. Pre-repair Investigation of CNC Machining Center

When running in idle mode, the spindle may reverse direction only at low speeds, and speed loss isn’t apparent. However, during high-speed spindle movement, especially during material cutting with deep cuts, the speed loss becomes much more obvious.

3. Cause Analysis

- The signal sent from the CNC machining center system to the spindle servo amplifier (inverter) may be affected by external interference.

- Voltage instability in the electrical circuit.

- The length or wear of the synchronous belt transmitting motion to the spindle may cause slippage.

- The synchronous belt connecting the spindle to the encoder may be too long or worn, leading to slippage.

- Signal lines from the encoder to the servo amplifier or system may be interfered with.

- The two supporting bearings of the spindle may have been damaged.

- Poor lubrication of the CNC machining center spindle.

4. Steps for Troubleshooting CNC Machining Center Spindle Fault

- Use a multimeter to measure the CNC machining center's electrical voltage. If the voltage is normal and other machines using the same power supply are operating correctly, voltage instability can be ruled out.

- Check the lubrication oil levels to ensure they are within the normal working range, and confirm the lubrication system is functioning properly, with no leaks or circuit faults. If the lubrication system works fine, lubrication issues can be ruled out.

- If lubrication isn’t the issue, check the bearings. Place a long rod (usually a tool) against the spindle bearing housing and press the other end against your ear. Listen for any unusual sounds. If there’s no abnormal sound, the bearings are unlikely to be the cause.

- If lubrication is not the issue, the fault may lie inside the spindle box. Open the spindle box to inspect the synchronous belt connection between the spindle motor and the spindle. Ensure the belt tension is appropriate.

- If the connection between the spindle motor and the spindle is fine but the synchronous belt between the spindle and encoder is worn, replace it with a new belt. After replacing the belt, the system should display normal spindle speed, and the CNC machining center spindle fault will be resolved.