In the world of CNC machining, a part’s function, aesthetics, and service life depend not only on dimensional accuracy but also on its surface finish. Choosing the right finish is a critical step in product design. This guide explores common CNC finishing processes, compares typical Ra values, and explains how each process affects appearance, feel, and performance.

What Is Surface Finish? Understanding Ra Values

Surface finish (also called surface texture or roughness) describes how smooth or rough a machined surface is compared to an ideal flat plane. The most widely used parameter is Ra (Roughness Average).

- Ra value: The arithmetic average of surface deviations (absolute values) from the mean line over a defined sampling length.

- Simple rule: The smaller the Ra, the smoother the surface.

- Units: Measured in micrometers (µm) or microinches (µin). 1 µm ≈ 40 µin.

CNC Surface Finish Comparison Table

The table below summarizes common CNC surface finish processes, typical Ra ranges, and practical visual & tactile effects.

| Ra (µm) | Ra (µin) | Process | Description | Visual & Tactile Effect |

|---|---|---|---|---|

| 12.5 – 25 | 500 – 1000 | Rough Machining | Heavy cuts with high feed and low speed for fast material removal. | Visual: Deep, obvious tool marks. Touch: Very rough; may feel sharp. |

| 3.2 – 6.3 | 125 – 250 | Standard Milling | Typical CNC finishing for many non-mating parts. | Visual: Uniform tool marks, matte. Touch: Noticeable texture, smoother than roughing. |

| 1.6 – 3.2 | 63 – 125 | Fine Machining | Higher spindle speed, lower feed, finishing tools reduce visible marks. | Visual: Faint tool marks, semi-matte. Touch: Smooth with light friction. |

| 0.8 – 1.6 | 32 – 63 | High-Precision Finish | Optimized parameters, sharp tooling, and stable machines to nearly eliminate marks. | Visual: Almost mark-free, satin-like. Touch: Very smooth — good for seals/low friction. |

| 0.4 – 0.8 | 16 – 32 | Deburring / Superfinishing | Manual or mechanical methods (magnetic polishing, edge rounding). Improves feel, may not change Ra drastically. | Visual: Rounded edges, consistent look. Touch: Smooth, no sharp edges. |

| 0.2 – 0.4 | 8 – 16 | Sandblasting | High-speed media (glass beads, alumina) to create uniform matte texture. | Visual: Even satin finish, hides tool marks. Touch: Fine, uniform frosted feel. |

| 0.1 – 0.2 | 4 – 8 | Anodizing (Aluminum) | Electrochemical oxide layer on aluminum; it replicates base texture and can be colored. | Visual: Can be dyed; reflects base finish (matte/satin). Touch: Hard, wear-resistant. |

| < 0.1 | < 4 | Polishing | Mechanical or chemical polishing to remove micro-irregularities; includes mirror finish. | Visual: Satin to mirror-like reflection. Touch: Extremely smooth, glass-like. |

How to Choose the Right CNC Surface Finish

Choosing a surface finish is more than picking a Ra number. Balance function, cost, and aesthetics.

1. Functionality First

- Moving parts / sealing surfaces: Low-friction finishes typically require Ra ≤ 1.6 µm.

- Coating / bonding bases: Slightly rough surfaces improve adhesion — Ra 3.2–6.3 µm. Sandblasting often helps.

- Aesthetic components: Consumer electronics often use sandblast + anodize for a premium matte look; decorative parts may request mirror polish.

[Comparison placeholder — anodized matte housing vs. mirror-polished trim.]

2. Cost Considerations

Rule of thumb: the smoother the required surface, the higher the cost. Ultra-low Ra demands slower feeds, more tool changes, tighter machine control, and additional finishing steps.

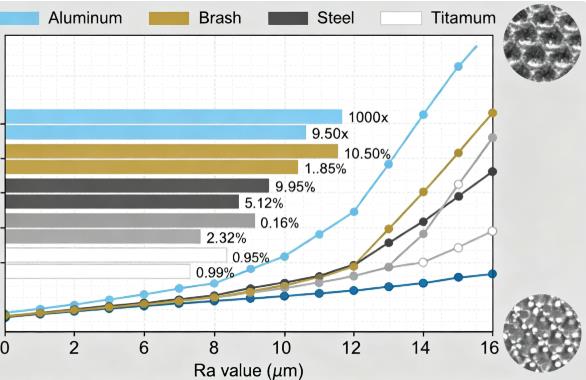

3. Material Factors

Different materials respond differently to finishing:

- Aluminum & brass: Easier to polish to mirror finish.

- Stainless steel & cast iron: Harder to polish to the same mirror-level; may plateau at higher Ra values.

[Image description: achievable Ra by material (Aluminum, Brass, Steel, Titanium).]

[Image description: achievable Ra by material (Aluminum, Brass, Steel, Titanium).]

Rapid Model:

Mastering CNC surface finish selection forms the bridge between design and manufacturing. Use the comparison table to understand how processes—from rough machining to mirror polishing—affect Ra values, appearance, and function. When designing a part, balance application, budget, and aesthetics. Most importantly: communicate exact Ra requirements with your manufacturer to ensure parts are both accurate and beautiful.

Rapid Model provides affordable CNC machining services and surface finishing solutions. With over 15 years of export experience, we offer customers real-time machining photos and a dedicated account manager for convenient communication. Click here to get in touch with us.