Some manufacturers engaged in phone housing production often ask: which machining center is best for processing mobile phone cases? Generally, customers who produce mobile phone cases have high requirements for machine precision and demand fast processing speeds.

I. Material Characteristics of Mobile Phone Case Machining

With the rapid innovation and development of smartphones and other digital devices, the demand for mobile phone case machining has grown steadily in recent years. Many manufacturers have gradually abandoned traditional plastic shells and switched to aluminum housings. Plastic shells have poor heat dissipation and limited aesthetics, whereas aluminum frames not only provide better heat dissipation but also look elegant and refined. Therefore, in the coming years, most major phone manufacturers will continue adopting aluminum materials — a very positive trend for the CNC machining industry.

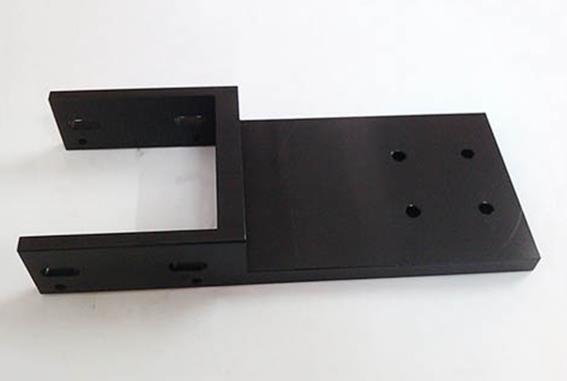

In mobile phone case production, the material form matters. Generally, CNC machining involves both profiles and plates, but phone housings are mainly made from plates rather than extruded profiles. Plate machining places higher demands on machine stability. Here, we will not discuss fixture design in detail, but it is indeed a critical factor. Fixtures greatly influence machining efficiency and accuracy. For example, if your machine can only process one case at a time, optimized fixture design may allow multiple cases — even up to ten — to be machined simultaneously, improving productivity significantly.

At Rapid Model, our CNC machining capabilities are well suited for such applications. We are equipped with multiple BT40 vertical machining centers and high-speed drilling and tapping centers, supporting aluminum housing production with high precision and consistency. Our experienced technicians can efficiently handle multi-part setups to improve throughput while maintaining stable quality across batches.

II. What Type of CNC Machining Center Is Suitable for Mobile Phone Metal Cases?

Mobile phone housings are typically made from aluminum. While aluminum itself doesn’t require extremely high rigidity, plate machining does. Therefore, a BT40 machining center is recommended for better stability and higher cutting capacity. Of course, programming quality and cutting tool selection also play an important role in achieving the desired results.

Since mobile phone case production demands high precision and surface finish, a machining center with an 8000 rpm spindle is not sufficient. It is better to choose a 20,000 rpm drilling and tapping center. Given that phone housings are small in size, using compact high-speed centers instead of large machines helps reduce cost while maintaining performance and finish quality.

The main advantage of drilling and tapping centers is speed. They use either a direct-drive spindle or an electric spindle. Most domestic small high-speed CNC machining centers use direct-drive spindles because electric spindles require higher technical precision. Only a few domestic manufacturers employ electric spindles, which are more commonly found in imported high-end machining centers.

Another major advantage of small high-speed machining centers is their ability to perform fine finishing on precision components. These machines can efficiently process parts with complex geometries and tight tolerance requirements, making them ideal for machining aluminum phone housings that demand both speed and accuracy.

Our Mobile Phone Metal Case Machining Services

Rapid Model provides precision CNC machining services for aluminum and magnesium alloy mobile phone housings. We specialize in:

- High-speed CNC milling and drilling for aluminum shells

- BT40 vertical machining center production for plate-type workpieces

- Precision finishing for complex and thin-walled housings

- Surface treatment options including polishing, sandblasting, anodizing, and coloring

- Rapid prototyping and low-volume manufacturing for new product development

With over 15 years of CNC machining experience, we deliver reliable and high-quality metal case solutions to global customers. For inquiries, visit www.rapid-model.com.