With over 20 years of industry experience, this article explores how 5-axis CNC machining leverages multi-axis coordination and intelligent control to achieve one-shot manufacturing of complex parts. This technology provides breakthrough precision and efficiency for aerospace, medical devices, and other high-end industries.

Overcoming Traditional Limitations in High-End Manufacturing

In high-end manufacturing, producing complex surfaces and high-precision components has always been challenging. Traditional 3-axis and 4-axis CNC machines are limited by their movement capabilities. When machining parts like turbine blades, orthopedic implants, or deep cavity molds, multiple setups are often required, which introduces cumulative errors and significantly reduces production efficiency.

5-axis CNC machining addresses these challenges with its multi-axis coordination and one-shot manufacturing capabilities, making it an essential technology in aerospace, medical devices, and high-end mold industries.

1. 5-Axis CNC Machining: More Than “Two Extra Axes”

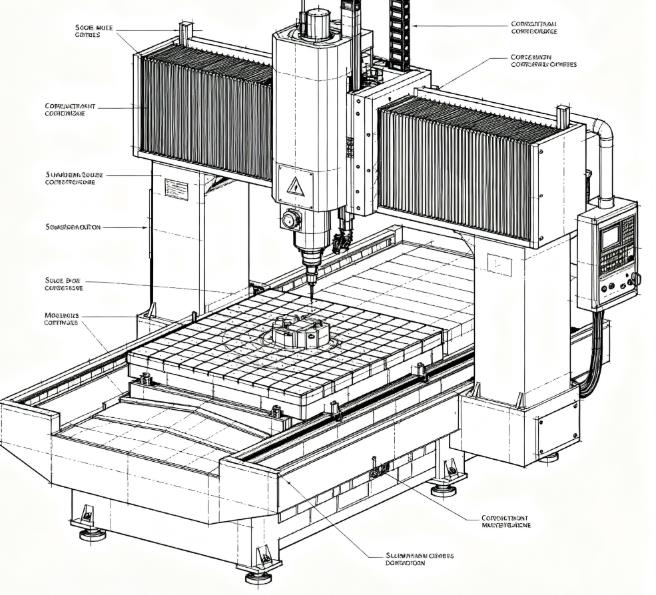

Many perceive 5-axis CNC as simply a 3-axis machine with two additional rotational axes. In reality, it is a comprehensive system combining precision mechanics, multi-axis motion control, and intelligent algorithms.

Its core principle involves the coordinated movement of X, Y, Z linear axes + A, C (or B, C) rotational axes, enabling the tool to approach the workpiece at any angle. This allows complex contours to be machined in a single setup, similar to the flexibility of a human hand.

(Image description:5-Axis CNC Machine Structure)

Illustration: Coordinated layout of X, Y, Z linear axes and A/C rotational axes, enabling multi-angle tool-to-workpiece interaction.

Unlike traditional methods where either the workpiece moves and the tool is fixed or vice versa, 5-axis CNC uses real-time error compensation algorithms to dynamically adjust axis movements, minimizing vibration and tool wear effects.

For example, when machining twisted, thin-walled turbine blades, 5-axis CNC ensures the tool maintains the optimal cutting angle, avoids collisions, and achieves tolerances within ±0.005 mm, far beyond the limits of 3-axis machining.

2. Three Core Advantages of 5-Axis CNC

Precision Breakthrough: From Cumulative Error to One-Shot Accuracy

In multi-step setups, each repositioning introduces alignment errors. Complex parts may require 3–5 setups, accumulating errors exceeding 0.1 mm, which cannot meet high-end industry requirements.

5-axis CNC eliminates setup errors by completing all operations in a single setup, supported by high-precision linear scales (resolution 0.1 μm) and spindle dynamic balancing, achieving micron-level accuracy.

(Image description:Medical implant machining scenario)

Example: 5-axis CNC machining of a femoral component for knee implants. Surface roughness Ra < 0.8 μm, meeting strict biocompatibility standards.

A medical device manufacturer using 5-axis CNC reduced femoral implant surface roughness to Ra < 0.8 μm, fully meeting biomedical surface requirements.

Efficiency Boost: Reducing Complex Part Cycle Time by 30–50%

In the automotive mold industry, deep cavity molds require frequent tool changes and angle adjustments on 3-axis machines, taking 15–20 days per mold.

5-axis CNC uses tilted spindle and synchronized multi-axis cutting to complete roughing, semi-finishing, and finishing in one setup, avoiding vibration-induced rework.

(Image description:5-axis machining process for automotive molds)

Example: Deep cavity mold machined with 5-axis CNC. Tilted tool entry prevents collisions and increases cutting efficiency.

Automotive mold manufacturers report cycle reductions to 8–10 days, 40% efficiency increase, and 25% reduction in tool wear, significantly lowering production costs.

Material Adaptability: Mastering Hard-to-Machine Alloys

Aerospace components increasingly use titanium alloys, high-temperature alloys, and composites, which are hard, have poor thermal conductivity, and are prone to tool burn or part deformation on conventional machines.

5-axis CNC optimizes cutting strategies (e.g., helical milling, trochoidal milling) and uses high-speed spindles (up to 20,000 rpm) with coated tools (ceramic, CBN) to efficiently machine these materials.

(Image description: Titanium Turbine disk machining scenario)

Example: Titanium turbine disk machined on 5-axis CNC. Cutting fluid and high-speed spindle maintain controllable temperature and prevent deformation.

An aerospace manufacturer achieved 60% higher cutting efficiency on titanium turbine disks and limited deformation to 0.02 mm, meeting high-temperature structural requirements.

3. From Technology to Industry Upgrade: Future Trends in 5-Axis CNC

Intelligent Integration: Digital twins simulate the machining process, optimizing cutting parameters before production. AI visual inspection can detect defects in real time and automatically compensate tool errors, enabling fully automated, closed-loop production.

Integrated Production: 5-axis CNC centers combined with robots, automatic loading/unloading, and warehousing systems form flexible production lines. Some high-end manufacturers achieve 24/7 operation and over 90% equipment utilization.

(Image description: 5-axis CNC intelligent production line)

Illustration: Flexible manufacturing unit with 5-axis CNC and robotic integration, enabling automated production and logistics.

Sustainable Manufacturing: Optimized coolant circulation (e.g., minimum quantity lubrication) and energy-efficient spindles reduce energy and fluid consumption. Some renewable energy companies report 60% lower cutting fluid usage and 15% reduced energy per part.

5-Axis CNC Machining, Driving the Precision Revolution

From aerospace components to medical implants, high-end molds, and critical renewable energy parts, 5-axis CNC machining delivers high precision, high efficiency, and material versatility.

For manufacturers seeking competitive advantage, adopting 5-axis CNC is not only the key to solving complex part challenges but also a strategic investment in future high-end manufacturing. With precision and efficiency driving innovation, 5-axis CNC will continue to redefine industry standards and set a new benchmark in advanced manufacturing.