In CNC machining, the number of axes directly influences a machine's capability, precision, and cost. Whether producing simple parts in high volumes or machining complex contoured components, selecting the right axis configuration is crucial for controlling cost and maximizing efficiency. This guide provides a detailed analysis of 3-axis, 4-axis, and 5-axis CNC machining, helping manufacturers make informed decisions on machine selection and process optimization.

1. CNC Machining Basics: Applications, Key Parameters, and Operational Tips

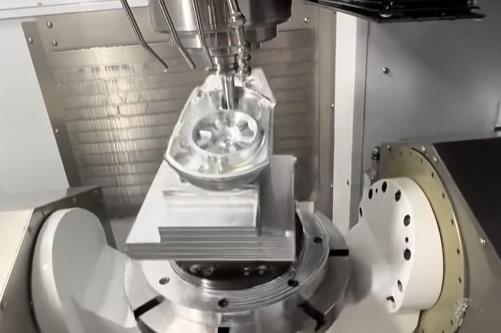

1.1 3-Axis CNC Machining: The Cost-Effective Entry-Level Option

Definition: A 3-axis CNC machine moves the tool or workpiece along three linear axes: X (left-right), Y (front-back), and Z (up-down). It cannot rotate the tool or workpiece, making it the most basic form of CNC machining.

Applications:

- Part Features: Flat surfaces, stepped surfaces, drilling, tapping, simple grooves, shallow contours.

- Industries: General machinery, consumer electronics components, standard fasteners, automotive low-value components.

- Production Volume: Medium to high-volume production where part geometry is fixed.

Key Technical Parameters:

| Parameter | Typical Range | Notes |

|---|---|---|

| Worktable travel | X: 500-2000mm, Y: 300-1500mm | Determines maximum part size |

| Spindle speed | 6,000–15,000 rpm | Lower speeds are suitable for harder materials like cast iron |

| Positioning accuracy | ±0.01–±0.03 mm | Not suitable for micron-level tolerance |

| Feed rate | 1,000–10,000 mm/min | Lower efficiency compared to multi-axis machines |

Operational Tips:

- Use vises or clamps; complex parts may require multiple setups, accumulating errors.

- Standard end mills, drills, and taps; no special tool angles required.

- Simple paths via CAD/CAM software (Mastercam, Fusion 360, or NX); easy for beginners.

(Image description:3-Axis CNC Machining Environment)

1.2 4-Axis CNC Machining: Efficiency Upgrade for Rotational Features

Definition: Adds one rotary axis (A or C axis) to the 3 linear axes, enabling multi-angle machining of cylindrical or circular features.

Applications:

- Circular holes/grooves, cylindrical surfaces, helical grooves, symmetrical curved surfaces.

- Automotive components, hydraulic valves, electric motor rotors, simple molds.

- Medium to small batch production where the rotary axis adds flexibility.

Key Technical Parameters:

| Parameter | Typical Range | Notes |

|---|---|---|

| Rotary axis travel | A: -120° to +120°, C: 360° continuous | Determines rotation range of the workpiece |

| Rotary axis accuracy | ±0.005°–±0.01° | Directly affects circular feature precision |

| Spindle power | 5–15 kW | Supports harder materials |

| Axis linkage | 3+1 interpolation | Cannot achieve full 5-axis simultaneous motion |

Operational Tips:

- Use indexing heads or 4-axis chucks; maintain concentricity ≤0.005 mm.

- Ensure the rotary axis doesn’t collide with fixture or tool during rotation.

- Establish a rotary axis coordinate system; compensate offsets after rotation.

(Image description:4-Axis CNC Machining Environment)

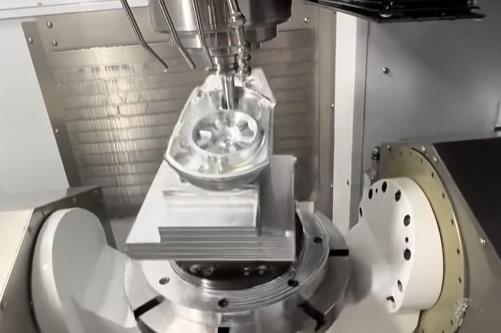

1.3 5-Axis CNC Machining: High-Precision Solution for Complex Surfaces

Definition: Combines 3 linear axes with 2 rotary axes, enabling full simultaneous motion for one-time setup machining of complex parts.

Applications:

- Freeform surfaces, deep molds, complex implants, multi-faceted parts.

- Aerospace, medical devices, high-end molds, renewable energy, precision instruments.

- Small batch, high-mix production minimizing error accumulation.

Key Technical Parameters:

| Parameter | Typical Range | Notes |

|---|---|---|

| Linkage accuracy | ±0.002–±0.005 mm | Supports micron-level tolerances |

| Rotary axis speed | A: 10–50 rpm, C: 50–200 rpm | Higher speeds increase efficiency of circular cuts |

| Spindle type | Electric spindle, 20,000–40,000 rpm | Suitable for high-speed cutting of difficult materials |

| Error compensation | Dynamic error compensation | Ensures long-term precision |

Operational Tips:

- Professional 5-axis software (NX, HyperMill); optimize tool angles to prevent collisions.

- Use digital twin or Vericut simulation to avoid trial-and-error cuts.

- Regular calibration of rotary backlash (monthly) and spindle balancing (quarterly).

(Image description:5-Axis CNC Machining Environment)

2. Cost Analysis: From Purchase to Operation

CNC machining costs derive from equipment investment, maintenance, labor, and material wastage. Axis count strongly impacts all cost components.

2.1 Equipment Purchase Cost

| Machine | Price (USD) | Cost Drivers |

|---|---|---|

| 3-Axis CNC | $7,000–$100,000 | Simple structure, no rotary axis |

| 4-Axis CNC | $40,000–$200,000 | Rotary axis drive, indexing system |

| 5-Axis CNC | $130,000–$700,000+ | High-precision control, dynamic compensation, rigid frame |

2.2 Annual Operation & Maintenance Costs

| Cost Type | 3-Axis | 4-Axis | 5-Axis |

|---|---|---|---|

| Consumables | $700–$3,000 | $1,500–$5,000 | $4,000–$10,000 |

| Calibration | $400–$1,500 | $1,000–$3,000 | $2,500–$7,500 |

| Energy | 6,000–18,000 kWh | 10,000–30,000 kWh | 25,000–60,000 kWh |

2.3 Labor and Material Wastage

- Labor: 3-axis $3,000–$5,000/month; 4-axis $5,000–$8,000/month; 5-axis + programmers $10,000–$20,000/month.

- Material Wastage: 3-axis 5–10%; 4-axis 3–6%; 5-axis 1–3% (initial trial cut may reach 15–20%).

3. Process Advantages and Disadvantages: Comprehensive Comparison

| Dimension | 3-Axis | 4-Axis | 5-Axis |

|---|---|---|---|

| Machinable Geometry | Flat & simple surfaces only | Cylindrical & circular features | Complex freeform, deep cavities, multi-faceted parts |

| Accuracy | Medium (±0.01–±0.03 mm) | High (±0.005–±0.01 mm) | Very high (±0.002–±0.005 mm) |

| Productivity | High for simple parts; low for complex | Efficient for circular features; multi-step for complex surfaces | High for complex parts, overkill for simple parts |

| Programming Difficulty | Low | Medium | High |

| Material Capability | Soft materials (aluminum, plastics, cast iron) | Medium-hard materials (steel, stainless) | Difficult alloys (titanium, high-temp alloys, composites) |

| Flexibility | Low | Medium | High |

| Total Cost | Low | Medium | High |

4. Selection Guidelines: Four-Step Decision Process

- Part Complexity: Simple flat/holes → 3-axis; Circular/multi-face → 4-axis; Complex freeform/odd shapes → 5-axis

- Tolerance Requirements: >0.03 mm → 3-axis; 0.01–0.03 mm → 4-axis; <0.01 mm → 5-axis

- Production Volume: High-volume → 3-axis; Medium/low → 4-axis; Small batch/custom → 5-axis

- Budget: < $40,000 → 3-axis; $40,000–$140,000 → 4-axis; > $140,000 → 5-axis

Rapid Model:

There is no "best" CNC machine — only the "right fit." 3-axis is reliable for standard production, 4-axis balances circular feature efficiency and cost, and 5-axis solves complex high-precision challenges. Selecting the optimal CNC machine requires evaluating part geometry, precision requirements, production volume, and budget to achieve the best cost-efficiency-quality balance.