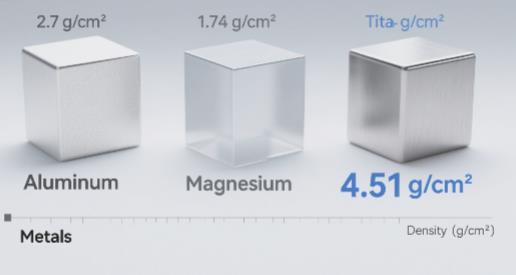

Lightweight metals (density < 5 g/cm³) are central to modern engineering design. Choosing between aluminum, magnesium and titanium is a trade-off among weight, strength, corrosion resistance, machinability and cost. This guide compares the three core metals, lists common grades, explains CNC machining behavior, and gives practical selection advice for prototypes and production parts.

What are lightweight metals?

Defined by density (typically below 5 g/cm³), lightweight metals allow designers to reduce mass without sacrificing performance. The most used structural metals are:

- Magnesium — density ~1.74 g/cm³

- Aluminum — density 2.70 g/cm³

- Titanium — density ~4.51 g/cm³

Other light metals like beryllium and lithium exist but are niche: beryllium is stiff yet toxic; lithium is primarily used electrochemically in batteries.

Common grades and alloys

Aluminum

Aluminum alloys are categorized by series: 1xxx (pure), 2xxx (Cu), 6xxx (Mg+Si — e.g., 6061), 7xxx (Zn — e.g., 7075). For CNC work, 6061-T6 is the general-purpose choice; 7075 when higher strength is required.

Magnesium

Magnesium alloys use codes like AZ (Al + Zn, e.g., AZ91), AM (Al + Mn), ZK (Zn + Zr). AZ91 is a common casting/machining alloy with balanced properties.

Titanium

Titanium comes in Grades 1–4 (commercially pure) and technical alloys like Ti-6Al-4V (Grade 5), which is the most widely used titanium alloy in aerospace and medical implants.

Advantages & disadvantages (quick comparison)

| Metal | Key strengths | Main drawbacks |

|---|---|---|

| Aluminum | Low cost, easy to machine, corrosion-resistant (oxide film), recyclable | Lower absolute strength than steel; limited high-temperature performance |

| Magnesium | Lightest structural metal, excellent damping, superb machinability | Poor corrosion resistance; chips/powder are flammable — strict safety needed |

| Titanium | Highest strength-to-weight, excellent corrosion resistance, biocompatible | Very expensive; difficult to machine; high tool wear |

CNC machining behavior and tips

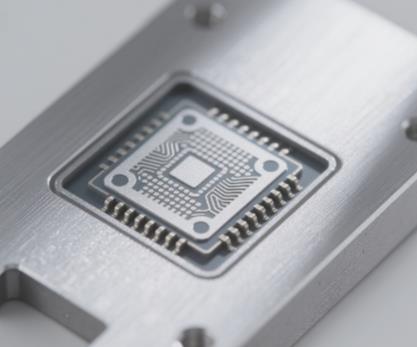

Aluminum — the CNC benchmark

Aluminum is extremely friendly for CNC: high spindle speeds, low tool wear, and excellent surface finish. Watch for built-up edge on some cast alloys (use sharp tools, appropriate lubrication). Typical picks: 6061-T6 for general parts, 7075 for high-strength components.

Magnesium — easy to cut, but risky

Machining magnesium is fast and produces low tool wear, but chips are combustible. Use dedicated chip extraction, non-sparking tooling and Class D fire suppression. Only machine magnesium where weight savings justify the safety and compliance costs.

Titanium — high-performance, high effort

Titanium generates heat at the tool edge and reacts with cutting tool materials. Expect slow spindle speeds, low radial depths, rigid machines, high-pressure through-tool cooling and premium carbide or coated tools. Titanium parts are costly to produce but required when performance is non-negotiable.

Cost and production considerations

From least to most expensive (both material + machining): Aluminum < Magnesium < Titanium. Aluminum offers the fastest cycle times and lowest tooling cost. Magnesium’s raw machining cost is low but facility upgrades and insurance raise total cost. Titanium yields long cycle times and frequent tool replacement — plan accordingly.

Conclusion — pick with intent

Choosing a lightweight metal is an engineering decision balancing mass, strength, corrosion resistance, machinability and cost. For prototypes and most production parts, aluminum (6061/7075) is the go-to. If every gram matters and you have certified facilities, magnesium can win. When top-tier strength, corrosion resistance or biocompatibility is mandatory, and cost is secondary, pick titanium.