Understanding the differences between cast iron and steel is crucial for selecting the right material and developing appropriate machining processes.

Below, I will explain in detail what cast iron and steel are, and highlight the key differences between them.

1. What is Cast Iron?

Cast iron is essentially an iron–carbon–silicon alloy with a very high carbon content (typically above 2.1%), where carbon mainly exists in the form of graphite.

Key characteristics: High carbon content + Graphite morphology

Production process: Iron ore, coke, and limestone are smelted in a blast furnace to produce pig iron. It is then remelted with scrap steel or recycled iron in a cupola or electric furnace and cast into molds. This is why castings made of cast iron are generally cast to shape.

Microstructure: The way graphite appears under a microscope determines the type and properties of cast iron:

- Gray Cast Iron: Graphite flakes. Good damping, wear resistance, and castability, but low strength and toughness.

- Ductile Iron: Graphite spheres (with Mg or Ce additives). Strength, toughness, and ductility close to steel.

- Malleable Iron: Produced by annealing white cast iron. Graphite clusters with moderate strength and toughness.

- White Cast Iron: Carbon exists as hard iron carbide. Very hard and wear-resistant but extremely brittle.

2. What is Steel?

Steel is also an iron–carbon alloy, but with a lower carbon content (usually less than 2.1%). Here, carbon mainly exists in the form of iron carbide (Fe3C).

Key characteristics: Low carbon + Carbide form

Production process: Pig iron is refined in a steelmaking furnace (converter, electric arc furnace), removing excess carbon and impurities, and alloy elements are precisely adjusted. The resulting steel is cast or forged into billets, then rolled or extruded into bars, plates, and tubes.

Microstructure: Depending on carbon content and heat treatment, steel may form ferrite, pearlite, austenite, or martensite—giving steel a wide range of mechanical properties.

3. Main Differences Between Cast Iron and Steel (CNC Machining Perspective)

| Property | Cast Iron | Steel |

|---|---|---|

| Carbon Content | High (>2.1%) | Low (<2.1%) |

| Carbon Form | Free graphite | Combined carbide |

| Manufacturing | Primarily cast | Refined, rolled, or forged |

| Mechanical Behavior | High compressive strength, brittle, low toughness (except ductile iron) | High strength + toughness, tunable via heat treatment |

| Machinability | Easier to cut, graphite helps chip breaking but produces abrasive dust | More difficult, long chips, high cutting force |

| Surface Treatment | Porous, coatings may adhere less well | Dense, ideal for plating and coating |

| Damping | Excellent | Poor |

| Wear Resistance | Good, graphite provides solid lubrication | Varies, can be improved with heat treatment |

| Cost | Lower, especially gray cast iron | Higher, but widely available stock |

| Applications | Engine blocks, brake discs, machine bases, housings | Shafts, gears, bolts, molds, tools, structures |

4. CNC Machining Considerations

Machining Cast Iron

Pros: Low cutting force, easy chip breaking, good surface finish.

Challenges: Produces abrasive graphite dust that wears tools and machine guideways. Requires effective dust removal.

Tooling: CBN tools for hardened cast iron, coated carbide tools for general machining.

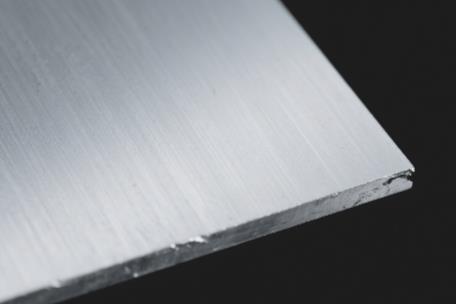

Machining Steel

Pros: Dense, predictable properties.

Challenges: Produces long chips, requires higher cutting forces, generates more heat.

Tooling: Coated carbide tools (TiAlN, AlCrN) for specific steels, HSS tools for light machining.

5. Advantages and Disadvantages

Cast Iron Advantages

- Excellent damping capacity

- Good wear resistance and self-lubrication

- Excellent casting fluidity for complex shapes

- Lower cost for complex parts

- High compressive strength

- Good machinability

Cast Iron Disadvantages

- Poor toughness and brittleness

- Low tensile strength

- Poor weldability

- Heavy weight

- Abrasive dust during machining

Steel Advantages

- Excellent strength and toughness

- Good formability and plasticity

- Good weldability

- Wide range of surface treatments

- Stable and predictable properties

Steel Disadvantages

- Higher cost

- Poor vibration damping

- Machining challenges (chip control, heat, work hardening)

- High density

- Corrosion issues (in carbon steels)

6. Selection Guidelines

| Factor | Choose Cast Iron When... | Choose Steel When... |

|---|---|---|

| Load Type | Mainly compressive, need damping | Tensile, impact, fatigue loads |

| Part Complexity | Very complex, cast shapes | Simpler, machinable from stock |

| Cost | Minimize cost for complex parts | High performance required |

| Performance | Need wear resistance and lubrication | Need strength, toughness, heat treatability |

| Secondary Process | Minimal welding | Reliable welding and coating |

7. Final Note

At Rapid Model, we provide professional metal casting and machining services. Our engineering team selects the best solution for your project so you can focus on design and planning without worrying about manufacturing challenges.