When starting a CNC machining project, one of the most important decisions is selecting the right material. Two of the most widely used options are aluminum (and aluminum alloys) and steel. Each material brings its own advantages and trade-offs in terms of strength, weight, cost, machinability, and corrosion resistance. Making the wrong choice could mean unnecessary cost, performance issues, or shorter product lifespan.

What Is Aluminum?

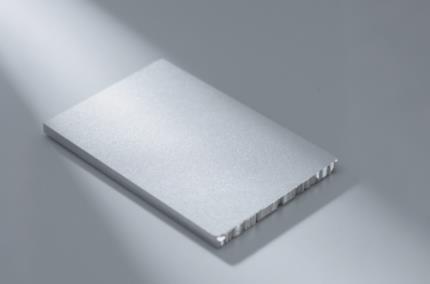

Aluminum (chemical symbol Al) is the most abundant metal in the Earth’s crust. Pure aluminum is lightweight, silver-white in appearance, and naturally resistant to corrosion due to a thin oxide film that forms on its surface.

Key Characteristics of Pure Aluminum

- Density: 2.7 g/cm³ (about one-third the density of steel)

- Strength: Relatively low in pure form

- Corrosion Resistance: Excellent, naturally self-protecting

- Machinability: Very good, easy to cut and form

- Conductivity: High electrical and thermal conductivity

- Weakness: Low absolute strength compared to steel

What Are Aluminum Alloys?

Aluminum alloys are created by adding elements like copper, magnesium, silicon, manganese, or zinc to pure aluminum. This dramatically improves strength and hardness while maintaining aluminum’s natural advantages: low weight, corrosion resistance, and ease of machining.

Common Aluminum Alloy Series for CNC Machining

- 1xxx (Pure Aluminum): High corrosion resistance, low strength (e.g., 1100).

- 2xxx (Al-Cu): High strength, lower corrosion resistance (e.g., 2024).

- 3xxx (Al-Mn): Good corrosion resistance, moderate strength (e.g., 3003).

- 5xxx (Al-Mg): Excellent corrosion resistance, good fatigue strength (e.g., 5052, 5083).

- 6xxx (Al-Mg-Si): Balanced strength, machinability, and corrosion resistance (e.g., 6061, 6082).

- 7xxx (Al-Zn): Extremely high strength, lower corrosion resistance (e.g., 7075).

What Is Steel?

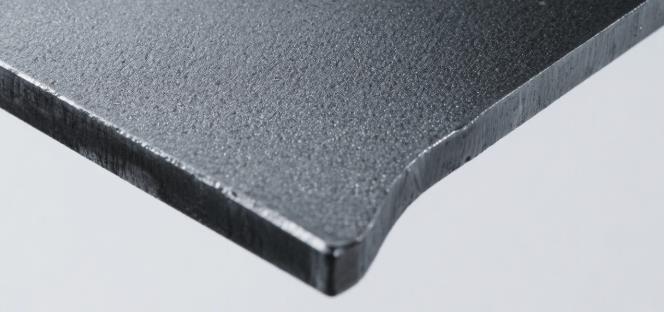

Steel is an alloy of iron and carbon, sometimes with additional elements like chromium, nickel, or molybdenum. It is known for its high strength, hardness, and wear resistance. Unlike aluminum, steel is heavy and dense, with a density of around 7.85 g/cm³.

Key Characteristics of Steel

- Density: Nearly three times that of aluminum

- Strength: Very high (far exceeds aluminum)

- Hardness: Excellent, ideal for wear-resistant parts

- Corrosion Resistance: Poor in carbon steel (unless treated); good in stainless steel

- Machinability: More difficult than aluminum

- Conductivity: Poor compared to aluminum

Aluminum vs Steel in CNC Machining: Core Differences

| Property | Aluminum/Aluminum Alloy | Steel |

|---|---|---|

| Density | Low (~2.7 g/cm³) → Lightweight | High (~7.85 g/cm³) → Heavy |

| Strength | Medium to high (depends on alloy) | Very high |

| Hardness | Lower → scratches easily | Much higher |

| Machinability | Excellent (fast speeds, less tool wear) | Fair to poor |

| Cost (Machining) | Lower (shorter cycle times) | Higher (longer cycle times) |

| Corrosion Resistance | Very good | Poor (unless stainless or coated) |

| Surface Finishing | Anodizing, coating, painting | Plating, galvanizing, painting |

| Conductivity | Excellent | Poor |

| Applications | Enclosures, brackets, heat sinks | Shafts, gears, tools |

How to Decide Between Aluminum and Steel

1. Is Weight a Critical Factor?

Yes: Choose aluminum.

No: Steel may be more cost-effective and stronger if weight is not an issue.

2. What Loads and Stresses Will the Part Face?

High loads: Steel is better.

Moderate to low loads: Aluminum is sufficient (7075 can rival mild steel).

3. What Is Your Budget?

Tight budget: Aluminum is usually cheaper to machine.

Performance priority: Steel is worth it for maximum strength.

4. What Is the Operating Environment?

Corrosive: Aluminum or stainless steel.

Dry environment: Carbon steel with coating works well.

5. Do You Need Conductivity?

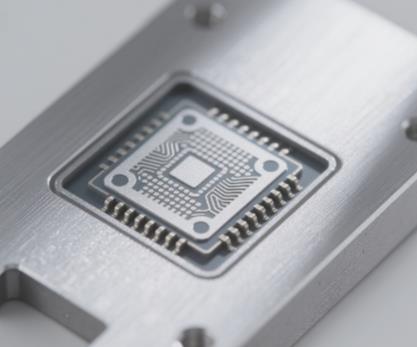

Yes: Aluminum is best for thermal and electrical conductivity.

No: Steel is acceptable.

Case Examples

- Drone Frames: Aluminum 6061 or 7075 for light weight and stiffness.

- Automotive Parts: Aluminum for panels and engine parts, steel for load-bearing areas.

- Industrial Tools: Steel for gears and shafts due to hardness.

- Consumer Electronics: Aluminum for housings (laptops, phones) for aesthetics and machinability.

Conclusion: Aluminum or Steel?

Choose Aluminum for lightweight, corrosion resistance, easy machining, and lower costs.

Choose Steel for maximum strength, hardness, or wear resistance when weight is less important.

In most projects, aluminum alloys like 6061 or 7075 are the starting point for CNC machining. However, when strength is critical, steel remains the best choice. Always consult your CNC machining supplier for tailored advice.