CNC Machining Parts: Top 5 Components for Precision Manufacturing

CNC (Computer Numerical Control) machining has become an integral part of modern manufacturing. With its ability to create high-precision components, CNC machining is widely used in industries such as aerospace, automotive, medical, and more. This article explores the top CNC machining parts that make precision manufacturing possible, their applications, and the benefits of each part.

What Are CNC Machining Parts?

CNC machining parts are the components produced using a CNC machine. These parts are typically made from metals, plastics, and composites and are designed to meet specific functional requirements. CNC machines use computer-controlled movements to shape the material into intricate designs with high accuracy.

By utilizing CNC technology, manufacturers can produce complex, detailed, and customized parts that cannot be achieved through traditional methods. Here are the five key CNC machining parts that play a crucial role in precision manufacturing.

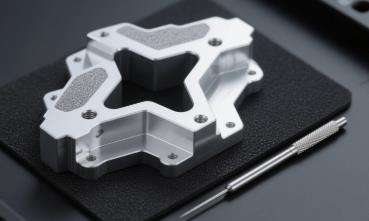

1. CNC Milling Parts: The Backbone of Precision

CNC milling parts are some of the most common types of machining components. These parts are created by rotating a cutting tool against a workpiece to remove material in precise increments. The process can create both complex and simple geometries, making it versatile for a range of industries.

Key Benefits:

- High precision for intricate designs.

- Ability to create 3D complex shapes.

- Suitable for a variety of materials, including metals and plastics.

Applications:

- Aerospace components like turbine blades and brackets.

- Automotive engine parts and transmission components.

Why CNC Milling Parts Are Critical

CNC milling parts are crucial in industries where precision is paramount. These parts ensure the highest level of accuracy for applications that require complex geometries, which is why they are commonly used in aerospace and automotive manufacturing.

2. CNC Turning Parts: Ideal for Symmetrical Components

CNC turning parts are produced using a CNC lathe machine that rotates the material while a cutting tool is applied to shape the material. These parts are ideal for creating cylindrical or spherical components, making them essential in industries that require high-tolerance, round-shaped parts.

Key Benefits:

- Perfect for producing round, symmetrical components.

- High-speed production, reducing lead times.

- Capable of turning both small and large components.

Applications:

- Automotive parts like shafts and bushings.

- Medical devices such as syringes and valves.

How CNC Turning Parts Enhance Manufacturing

CNC turning parts excel in creating components with rotational symmetry, ensuring consistent quality and faster production times. Their use in the automotive and medical industries showcases their importance in high-demand applications.

3. CNC Lathe Parts: A Subcategory of Precision Turning

CNC lathe parts are often confused with CNC turning parts, but the lathe machine's primary role is to achieve even more precision and versatility in shaping materials. CNC lathes are used for smaller, more complex parts that require intricate shaping and cutting.

Key Benefits:

- Precision in creating complex shapes with high detail.

- Capable of handling high volumes of production.

- Flexible for a range of materials and sizes.

Applications:

- Precision engineering components.

- Parts for electronics, like connectors and housings.

Why CNC Lathe Parts Matter

CNC lathe parts are essential for manufacturers who need to produce intricate, high-precision components, especially in industries like electronics and medical devices. The versatility of CNC lathes ensures that even complex shapes can be accurately formed.

4. CNC Drilling Parts: Perfect for Holes and Depth Precision

CNC drilling parts are used when creating holes, slots, and pockets in materials. CNC drilling involves the use of rotating drills to create precise holes at exact depths and locations. This type of machining is commonly used for creating parts that require high hole accuracy.

Key Benefits:

- Creates high-precision holes with exact depth control.

- Suitable for both small and large volumes of parts.

- Can drill holes at different angles.

Applications:

- Aircraft parts like wing spars and engine mounts.

- Construction equipment requiring hole alignment and depth precision.

The Importance of CNC Drilling Parts

CNC drilling parts are necessary for industries that require exact hole placement and depth, such as aerospace and heavy machinery. The precision of CNC drilling ensures structural integrity in critical components.

5. CNC Laser Cutting Parts: The Precision of Light

CNC laser cutting parts are manufactured using a laser to cut materials with high precision. This method uses a focused laser beam to melt, burn, or vaporize the material, creating clean edges and intricate patterns.

Key Benefits:

- High precision with minimal heat-affected zones.

- Clean cuts without material deformation.

- Suitable for a variety of materials, including metals, plastics, and ceramics.

Applications:

- Electronics housings and circuit boards.

- Automotive parts like body panels and trims.

Why CNC Laser Cutting Parts are Essential

CNC laser cutting parts provide an advanced solution for industries that require high-speed, accurate cutting. This technology is particularly important for manufacturing clean-cut components in electronics and automotive sectors.

Why CNC Machining Parts Matter in Modern Manufacturing

In conclusion, CNC machining parts are indispensable for achieving the level of precision and efficiency needed in modern manufacturing. From CNC milling parts to laser cutting parts, each part plays a critical role in producing complex, high-quality components for a variety of industries. By incorporating these precision machining techniques into their production processes, manufacturers can ensure the highest levels of accuracy, reduce material waste, and improve overall product performance.