Real-World Problem Solving: When tapping tools snap in tough materials like titanium or struggle to handle fine threads like 4"-80 UNJ, thread milling becomes the solution. Industry reports reveal the following benefits of thread milling:

- 47% longer tool life in Inconel compared to tapping (MachiningCloud 2023 report)

- 30% cost reduction on holes larger than 1" diameter (Boeing SAE case study)

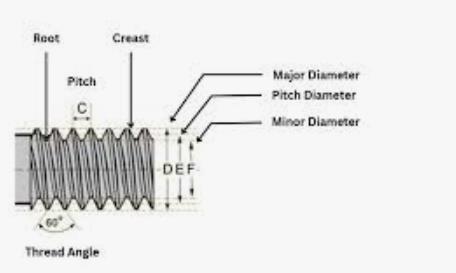

2. The Physics Behind Thread Milling

Core Innovation: Thread milling uses a smaller tool diameter compared to tapping, enabling it to cut threads in larger holes with enhanced precision.

Helical Interpolation: The tool moves simultaneously in both a circular (X/Y) and axial (Z) motion, creating threads with superior geometry.

Chip-Load Advantage: Thread milling generates 70% less cutting force than conventional tapping, making it ideal for hard-to-machine materials and reducing tool wear.

Tool Path Visualization:

3. Thread Mill Selection Matrix (Global Standards)

Selecting the right thread mill depends on the material, thread requirements, and machining conditions. Below is a helpful guide:

| Tool Type | Best For | Speed/Feed Tips | Top Brands |

|---|---|---|---|

| Straight Flute | Soft alloys, prototyping | 300-500 SFM, 0.003″/tooth | Kennametal |

| Helical Flute | Stainless, aerospace | 150-250 SFM, 0.002″/tooth | Sandvik Coromant |

| Single-Point | Hardened steels (>45 HRC) | 80-120 SFM, 0.001″/tooth | Iscar |

NASA-Approved Practice: For A286 superalloy fasteners, use variable-helix tools with AlTiCrN coating (Ref: MSFC-STD-3676)

4. When to Choose Thread Milling vs. Tapping

Dominate These 5 Scenarios with Thread Milling:

- Large Diameters: Thread M120 holes on horizontal mills.

- Blind Holes: Perfect threads to the bottom with controlled retract.

- Interrupted Cuts: Reliably thread cast iron with sand inclusions.

- Exotic Materials: Hastelloy, Waspaloy, and GRCop-42 copper alloys.

- Custom Threads: Produce UNJ, ACME, and NPT in the same setup.

Avoid Thread Milling When:

- Mass-producing M8×1.25 threads in 6061-T6 aluminum.

- Limited CNC interpolation capability.

- Shop only has manual machines.

5. Global Machining Parameters Cheat Sheet

| Material | SFM | IPT | DOC | Coolant Strategy |

|---|---|---|---|---|

| 7075-T6 Aluminum | 650 | 0.004″ | 1.5×Pitch | Air blast + MQL |

| 17-4PH Stainless | 180 | 0.0025″ | 1×Pitch | 8% Emulsion @ 800 psi |

| Ti-6Al-4V ELI | 110 | 0.0015″ | 0.8×Pitch | Through-tool cryo |

| D2 Tool Steel | 75 | 0.001″ | 0.5×Pitch | Dry machining |

Euro-Specific Tip: For CE-compliant shops, use minimum quantity lubrication (MQL) when machining copper alloys (per EU Directive 2023/178).

6. Advanced Troubleshooting Guide

| Symptom | Root Cause | Fix | Prevention |

|---|---|---|---|

| Thread chatter | Excessive tool overhang | Reduce L:D ratio below 4:1 | Use hydraulic expansion holder |

| Dimensional drift | Thermal expansion | Implement compensation +0.0003″/inch | Pre-cool workpiece |

| Poor surface finish | Chip recutting | Program full retract every 3 threads | Use compressed air blast |

| Tool fracture | Incorrect helix direction | Verify climb vs. conventional milling | Run spindle verification test |

7. Programming Pro Tips (Fanuc/Heidenhain/Siemens)

G-Code Essentials for Thread Milling:

G17 G90 G54 ; XY plane, absolute, work offset

G43 H01 Z1.0 ; Tool length comp

M03 S3500 ; Start spindle

G02 X0 Y0 I-0.5 Z-0.1 F20.0 ; Helical interpolation

; Repeat for thread depth (Z-increment = pitch)

G00 Z2.0 M05 ; Retract, stop spindle

CAM Software Settings:

- 85% radial engagement maximum

- Lead-in/lead-out ≥ 30° arc

- Always use centerline programming

8. 2024 Industry Innovations

- Smart Tooling: Kennametal’s NOVO chipbreaker technology reduces torque by 40%.

- Hybrid Processing: DMG MORI’s MillTap machines combine drilling and threading for faster setups.

- AI Optimization: Siemens NX Thread Advisor auto-generates cycle times, optimizing efficiency.

- Ultra-Precision: Sandvik’s CoroMill® 390 achieves Ra 0.8 μm finish in titanium.

9. Machinist’s FAQ (Field-Tested Answers)

- Q: Can I thread mill left-hand threads?

A: Yes, simply reverse the spindle rotation (M04) and adjust the helix direction (G03 for RH → G02 for LH). - Q: What’s the minimum hole size?

A: Commercially available tools can handle holes as small as #0-80 (0.060″/1.52mm) using micro-grain carbide tools. - Q: How to calculate cycle time?

A: Formula: Time = [(Depth ÷ Pitch) + 2] × (π × Hole Dia ÷ Feed Rate) + rapid moves. - Q: What are OSHA coolant requirements?

A: Use NSF-registered fluids with ≤0.5 mg/m³ aerosol exposure (29 CFR 1910.1000).

10. Partner Selection Criteria

When selecting a machining partner for mission-critical threads, prioritize the following certifications:

- AS9100 Rev D aerospace quality systems

- Nadcap AC7114 special process approval

- On-site CMM with Geomagic® Control X

“Demand these certifications for guaranteed thread quality and reliability.” – J. Richardson, Former SpaceX Manufacturing Lead

▼ Get Instant Thread Milling Solutions

Upload your drawing to receive a comprehensive DFM analysis within 3 hours:

- Material-specific tooling recommendations

- ISO 9001:2015 compliant process sheets

- Competitive pricing with ITAR options