The Integration and Application of Precision Automation and CNC Machining

With the rapid development of manufacturing technology, the combination of precision automation and CNC machining has increasingly become a critical direction in modern industry. Precision automation, through efficient control systems and precise motion control, not only drives the automation of production processes but also improves production efficiency and product quality. On the other hand, CNC machining, with its high precision and flexibility, meets the growing demands for processing complex parts. The synergy between the two makes manufacturing processes more efficient, precise, and intelligent, pushing innovation and advancement in various industries.

Overview of Precision Automation

Precision automation devices are playing an increasingly important role in modern industry. With continuous advancements in technology, especially driven by artificial intelligence, machine learning, and the Internet of Things (IoT), precision automation is gradually evolving toward more intelligent and networked systems. These devices, with their precise motion control and high levels of automation, significantly improve the efficiency, stability, and safety of production processes. Whether in automotive manufacturing, electronics assembly, or precision instrument processing, the widespread use of precision automation devices has greatly enhanced production efficiency, ensured product quality, and reduced the need for manual operations.

The Relationship Between Precision Automation and CNC Machining

There is a close interdependence between precision automation and CNC machining, which can be seen in several key areas:

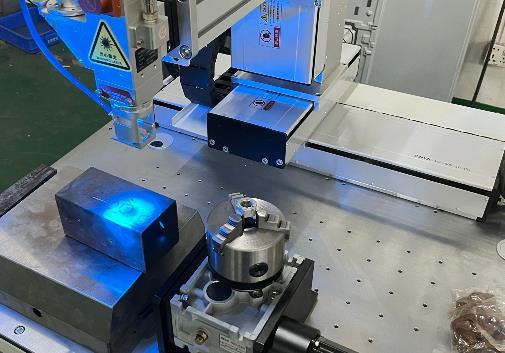

- Precision Automation Devices for CNC Machining: Precision automation devices, such as fixtures, are an essential part of CNC machining. These devices ensure the stable positioning of workpieces during CNC machining, guaranteeing machining accuracy.

- Automation Enhancing CNC Machining Efficiency: Precision automation devices typically include electronic controls, hydraulic components, pneumatic elements, etc. These automated control functions can significantly improve the efficiency and precision of CNC machining.

- CNC Technology as the Foundation of Automation: CNC technology is the foundational technology for realizing automation, flexibility, and integrated production in modern manufacturing. Precision automation devices often rely on CNC technology to achieve their automated functions.

- Complementary Relationship: CNC machining requires precision automation technologies to achieve efficient and high-precision processing, while precision automation needs CNC technology control to realize its automated functions.

Precision Automation Technology in CNC Machining

CNC machining plays an indispensable role in precision automation. Below are several key precision automation technologies used in CNC machining:

- Servo Drive Systems: Servo drive systems control the movement of CNC machine axes with high precision, ensuring efficient and precise cutting operations. Whether for complex machining processes or fine parts, servo systems guarantee the accurate positioning of tools at the correct speed and force.

- Automatic Measurement and Inspection Systems: Automatic measurement and inspection systems monitor the size and shape of workpieces during the machining process to ensure they meet design specifications. These systems can automatically detect dimensional deviations using sensors or laser scanning technologies and make adjustments to machining parameters if necessary.

- Automatic Tool Change Systems: In traditional machining, operators manually change tools for different operations, which is time-consuming and error-prone. CNC machine tools equipped with automatic tool change systems (ATC) can automatically switch between tools, greatly improving machining efficiency and precision.

- Automatic Material Handling Systems: These systems, including robotic arms and conveyor belts, automate the transportation and unloading of materials. In precision aerospace part production, for example, raw materials are automatically transported to machining positions, and once machining is complete, robotic arms transport the finished parts to inspection devices for further quality control.

Practical Applications of Precision Automation in CNC Machining

With the advancement of precision automation, CNC machining has seen significant improvements, particularly in high-precision fields. Precision automation not only increases machining efficiency but also makes manufacturing processes more flexible and intelligent. By integrating sophisticated system control and real-time data feedback, production can be adjusted according to current conditions to ensure precision and high quality.

For example, in industries such as aerospace, automotive manufacturing, and medical devices, the integration of precision automation and CNC machining improves both production efficiency and the precision of parts. This is especially critical in industries that require strict adherence to part geometry and dimensional tolerance.

Future Development of Precision Automation and CNC Machining

As smart manufacturing becomes more widespread, the integration of precision automation and CNC machining will continue to deepen. Future precision automation systems will not only meet traditional production needs but will also incorporate self-learning, self-regulating, and real-time optimization capabilities. By combining advanced technologies such as artificial intelligence, machine learning, and big data analytics, precision automation devices will continuously optimize production, reduce costs, and even predict equipment failures, leading to proactive maintenance and minimizing downtime.

In addition, with the application of 5G technology and IoT, precision automation devices will become even more intelligent and interconnected. By enabling real-time data exchange, manufacturing processes will become more transparent, and resource allocation and production scheduling will be more precise. This will not only increase production efficiency but will also drive the intelligent management of global supply chains, supporting innovation and upgrades in the global manufacturing sector.

Conclusion

The deep integration of precision automation and CNC machining has not only driven the automation and intelligent processes in manufacturing but has also provided strong guarantees for high-precision and efficient production. With continuous technological advancements, the synergy between these two will become even more seamless, propelling industries towards greater intelligence and automation. The combined development of precision automation and CNC machining will inject innovative momentum into manufacturing and provide strong support for global industrial advancement.