A product's skeleton often determines its lifespan and reliability. But when that skeleton is a metal frame required to bear extreme loads, integrate complex systems, and withstand harsh environments—do you truly understand the chasm between the digital model and physical reality? The distinction between computerized design and precision manufacturing is far more than just drawing and cutting; it dictates your product's performance, failure risk, and ultimately, its market reputation. Many dismiss this as mere "outsourced machining," yet ignoring its engineering depth can lead to catastrophic structural failure, causing your entire project to collapse. This is precisely the risk we at Rapid Model vow to eliminate for you, because Speed and Precision are inseparable parts of our DNA!

Demystifying Skeleton Engineering: Core Definitions

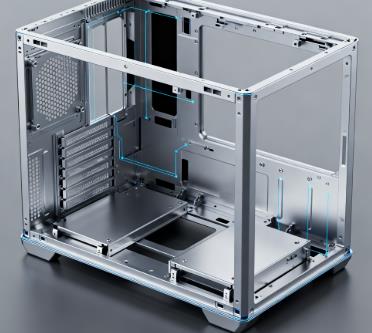

Computerized Metal Frames do not refer to simple metal boxes. They represent a structural core, born in the digital realm, optimized through simulation, and carved with micron-level precision via Computer Numerical Control technology. This isn't just manufacturing; it's an engineering symphony of strength, precision, and efficiency!

What Truly Defines a Computerized Metal Frame?

The true soul of a computerized metal frame lies in the seamless transition from "Design for Manufacture." It begins with topology optimization, shedding every redundant gram of material in the virtual world; and is realized through CAM programming, translating optimal toolpaths into reality. Imagine aerospace brackets that are feather-light yet indestructible, or medical device housings that perfectly mate with countless sensors—this is a feat unattainable by traditional sheet metal. It's a testament to the astounding power of a perfect digital thread merging with the physical world!

High-Performance Frame Material Examples

| Material Type | Typical Frame Applications | Core Advantages |

|---|---|---|

| Aluminum 6061/7075 | Robot Skeletons, Drone Airframes, Precision Instrument Housings | Excellent Strength-to-Weight Ratio, Superior Corrosion Resistance, Good Machinability |

| Stainless Steel 304/316 | Medical Equipment, Food Processing Machinery, Marine Structural Components | Exceptional Strength & Hardness, Outstanding Corrosion Resistance, Hygienic |

| Titanium Alloy TC4 | Aerospace Components, High-Performance Roll Cages, Medical Implant Supports | Remarkable Strength-to-Weight Ratio, Excellent Biocompatibility, Extreme Temperature Resistance |

Engineering the Perfect Frame: Walking the Tightrope Between Lightweighting and Ultimate Strength

Designing a superior metal frame is far from simply "thickening the plate"; it's a delicate balance between lightweighting, rigidity, fatigue resistance, and manufacturing cost. I've witnessed countless projects fail due to a team's ignorance of DFM, resulting in unmanufacturable designs or micro-cracks under load. Selecting the right material is merely the first step on this journey!

Key Attributes Defining Frame Performance

| Attribute | Description | Rapid Model's Focus |

|---|---|---|

| Specific Strength | The ratio of material strength to its density | Maximize this ratio for lightweighting and high load-bearing |

| Stiffness/Rigidity | Resistance to elastic deformation | Ensure geometric stability of the frame through structural design |

| Fatigue Strength | Resistance to failure under cyclic loading | Optimize geometry to eliminate stress concentrations |

| Dimensional Stability | Ability to maintain shape under thermal and load variations | Strict control via material selection and stress-relief processes |

| Damping Characteristics | Ability to absorb vibrational energy | Optimize through material and structural design to reduce resonance |

Design for Manufacturability: The Make-or-Break Line

Achieving a frame that is both light and robust in precision metal machining is fraught with intricate design challenges. Sharp corners, uneven wall thicknesses, and poorly designed ribs become "time bombs" for stress concentration. Furthermore, residual stresses from machining can silently release during use, causing frame warping—a fatal flaw for any high-precision equipment. Designers must deeply understand tool accessibility, minimum inner radius, and material grain direction. Add to that our commitment to simulating every feature, ensuring it works not just on screen, but withstands real-world forces; it's a Herculean task, demanding nothing less than the absolute pinnacle from our Rapid Model CNC machining services!

How Rapid Model Forges Your Digital Skeleton: The Perfect Fusion of Speed and Precision

At Rapid Model, our core philosophy is rooted in one undeniable truth: A perfect frame must be delivered fast. Time is money, but never at the expense of quality. For prototyping or low-volume production, we inject this belief into every step.

Advanced Manufacturing Technologies for Rapid Iteration

For metal frame prototypes, our 5-Axis CNC Machining Centers are crucial. They allow us to sculpt complex geometries from a solid metal blank in a single setup, maximizing accuracy and eliminating errors from multiple fixturing. But let's be honest, this is just the beginning! To achieve impeccable delivery speed, we integrate automated CAM programming and toolpath optimization systems, slashing the time to convert your CAD model into machine code by 70%. This isn't just fast; it's intelligently fast, a marvel of modern manufacturing engineering!

Iron-Clad Quality Control Ensuring Structural Integrity

Our quality control protocol is the bedrock of your confidence. For every structurally critical frame, we employ not only CMM for full dimensional inspection but also advanced residual stress testing and non-destructive testing techniques to ensure no hidden flaws exist within the material that could lead to premature failure. Every batch of parts undergoes rigorous visual and tactile inspection to detect even the slightest tool mark or burr. This Almost paranoid holistic approach ensures every frame you receive is ready to shoulder the responsibility of being your product's "skeleton."

Transparent Pricing & Lightning-Fast Response

We firmly believe that extreme speed and reliable quality should not be shrouded in mystery. Rapid Model advocates for radically transparent pricing because you deserve to see the value behind every cent. Our quotes clearly list material costs, machining hours, specialized tooling expenses—and crucially, the cost of extra resources we dedicate to accelerated delivery. This clear communication empowers you to make informed decisions, ensuring your project moves at lightning speed without any unwelcome financial surprises or quality pitfalls.

Choosing the Right Frame Solution for Your Application

The choice between an "adequately strong" and an "optimally designed" frame will determine whether your product is mediocre or exceptional. This decision impacts product lifespan, user experience, and brand reputation; handled poorly, it's the catastrophic you least want to see.

Cross-Industry Application Examples

| Industry | Typical Frame Needs | Rapid Model's Core Value |

|---|---|---|

| Robotics & Automation | High Rigidity, Lightweighting, High Dynamic Stability | Achieve unparalleled performance via Topology Optimization & 5-Axis Machining |

| Aerospace | Extreme Specific Strength, Fatigue Resistance, Reliability | Utilize premium materials like Titanium with NDT for absolute certainty |

| Medical Devices | Biocompatibility, Compact Structure, Flawless Surface Finish | Deliver medical-grade Stainless Steel & Titanium, unifying function and aesthetics |

| High-End Consumer Electronics | High Aesthetic Demands, Complex Integration, Efficient Thermal Management | Fuse functionality with exquisite aesthetics to elevate product feel |

Partnering to Seize Market Opportunities

Whether your need is a robot skeleton, medical device chassis, or exploration instrument frame, choosing the right manufacturing partner is decisive. Rapid Model is not just your machine shop; we are your trusted Rapid Prototyping & Manufacturing Advisor. We possess the technical expertise to rapidly transform complex designs into reliable reality, backed by advanced facilities and an unwavering commitment to being "Fast, Not Rough".

Partner with us, and rest assured that your product's skeleton will not only be robust but will be born at a pace that outruns the market. This is a partnership built on Speed, Precision, and Mutual Success!

Contact Us Now for Your Custom Frame Solution and Instant Quote!