In metal fabrication, the manufacturing of cylinder head components requires meticulous planning to prevent distortion, maintain precision, and ensure structural integrity under high-pressure conditions. These critical parts are central to performance in automotive, aerospace, and heavy machinery. However, their complex internal geometries and thin-walled sections make them prone to thermal distortion, sealing failures, and stress cracking.

If the process planning or quality control is inadequate, even with increased machining allowances and extended cycle times, achieving consistent results in serial production remains challenging. This article examines a real-world case study on manufacturing a high-performance cylinder head, sharing practical insights into process and quality control solutions.

Manufacturing Challenges for Cylinder Head Components

Cylinder heads feature intricate networks of coolant passages, oil galleries, and valve seats. They must maintain perfect sealing while withstanding extreme thermal and mechanical stresses. However, their thin-walled sections and varying material thickness often lead to unpredictable deformation during machining, poor surface finish in critical areas, and stress concentration around combustion chambers.

Post-Machining Distortion

Cylinder heads are susceptible to warping due to residual stresses from casting and heat treatment. As material is removed during CNC machining, these stresses redistribute, causing the component to deform. This can compromise the head gasket seal and lead to engine failure.

Surface Finish Inconsistency

The complex, deep-pocketed geometries of intake and exhaust ports make them difficult to machine consistently. Tool deflection and vibration can cause visible chatter marks, reducing airflow efficiency and creating potential sites for crack initiation under thermal cycling.

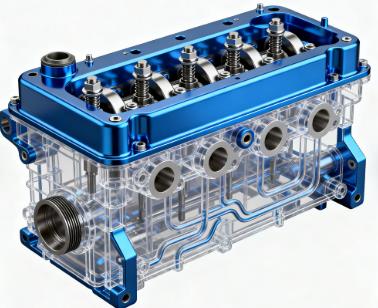

Real-World Case: High-Performance Aluminum Cylinder Head

Here we examine the manufacturing process for a high-performance aluminum cylinder head, sharing how strict tolerances and distortion control were achieved in production.

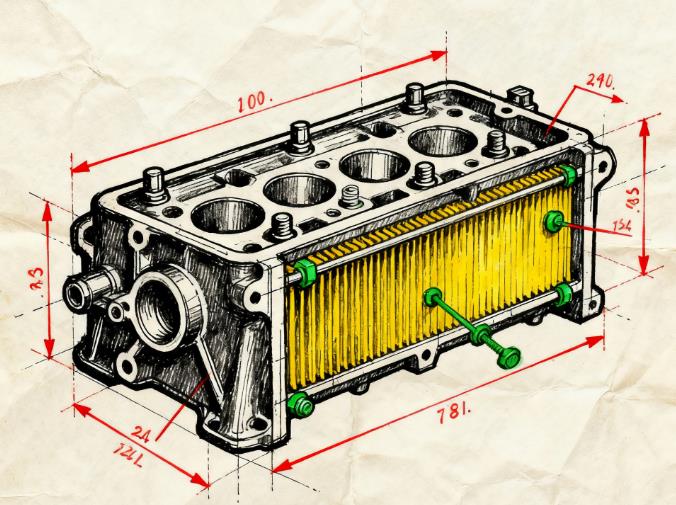

Product Specifications

- Material: A356-T6 Aluminum

- Dimensions: 650mm × 300mm × 150mm

- Critical Features: Integrated exhaust manifold, dual overhead cam design

- Production Quantity: 500 units

Manufacturing Requirements

- Combustion face flatness must be within 0.05mm across entire surface.

- Valve seat concentricity with guide holes must not exceed Φ0.03mm.

- All port surfaces require mirror-finish honing with Ra ≤ 0.4μm, free of micro-cracks.

- Must pass rigorous thermal cycling tests between -40°C and 150°C without failure.

Manufacturing Challenges

- Controlling distortion from residual stresses in the cast aluminum material.

- Achieving consistent surface finish in deep, complex port geometries.

- Maintaining critical dimensional relationships between valve guides and seats.

- Balancing production efficiency with stringent quality requirements.

Problems with Traditional Manufacturing Solutions

The conventional approach began with T6 heat treatment of the casting, followed by rough machining of the combustion face on 3-axis CNC. Subsequent operations used specialized fixtures and multiple setups to complete valve guides, seats, and coolant passages. Port finishing relied heavily on skilled manual polishing.

This method appeared "flexible" in equipment requirements but revealed significant limitations in production:

Limitations of This Approach

- Multiple setups introduced cumulative errors, making it difficult to maintain critical tolerances.

- Surface quality depended entirely on technician skill, resulting in inconsistent performance.

- The dispersed process flow created bottlenecks, with excessive time spent on workpiece handling and fixture adjustments.

Optimized Manufacturing Solution

1. Optimized Process Sequence and Datum Strategy

Implemented a "one-setup" machining strategy using a common datum system throughout the process:

- CNC1 (Rough Machining & Datum Establishment): Create consistent locating surfaces and datum holes.

- CNC2 (5-Axis Precision Machining): Complete all valve seats, guide holes, and critical features in a single clamping.

- CNC3 (Dedicated Honing): Programmable honing of intake and exhaust ports for consistent surface finish.

2. Stress Relief and Distortion Compensation

Added vibration stress relief after casting and a stress relief cycle after rough machining. Implemented compensatory toolpaths in CNC2 based on measurement data from first articles to proactively counter predictable deformation.

3. Smart Manufacturing with In-Process Verification

Integrated touch probes on CNC2 to scan the combustion face before finishing operations, automatically adjusting the toolpath to account for actual workpiece geometry. Performed in-process measurement of critical features immediately after machining.

4. Automated Port Surface Finishing

Replaced manual polishing with CNC-controlled honing equipment that follows the CAD model of each port. This ensured identical surface texture and geometry across all parts while eliminating the risk of micro-cracks from manual processes.

5. Enhanced Production Capacity and Quality

By streamlining operations, reducing setups, and automating critical processes, cycle time was reduced by 45%. More importantly, first-pass yield on thermal cycle testing improved from 65% to over 98%.

From Challenge to Reliable Production

Successfully manufacturing complex metal fabrications like cylinder heads requires systematic integration of process planning, stress engineering, and quality control. Each component presents unique challenges that demand customized solutions.

This case demonstrates how combining casting optimization, CNC process refinement, and intelligent quality verification creates a pathway to both exceptional performance and reliable volume production.

Your Rapid Manufacturing Partner: Rapid Model

At Rapid Model, we understand the challenges in moving complex metal components from concept to production. We offer comprehensive solutions from rapid prototyping to low-volume manufacturing, including precision casting, CNC machining, and rigorous material testing. With deep expertise in automotive and aerospace applications, our team ensures your cylinder head components—and all critical metal fabrications—meet the most demanding performance standards while accelerating your time to market.

Choose Rapid Model for speed, reliability, and performance excellence in every component.