In mechanical engineering and manufacturing, threaded fasteners serve as fundamental components that enable reliable connections, power transmission, and sealing functions across countless applications. From automotive chassis bolts to aerospace engine components, from structural steel connections to consumer product assemblies, threads represent the essential "mechanical bonds" that determine equipment reliability, safety, and service life.

Among global thread standards, the American Unified Thread Standard (UN series) stands as a cornerstone specification in international manufacturing, fastener industries, and global supply chains. Within this system, UNC (Unified National Coarse) threads and UNF (Unified National Fine) threads emerge as the two most prevalent types, each with distinct structural characteristics, performance attributes, and application scenarios that directly impact engineering decisions, procurement specifications, and manufacturing processes.

This comprehensive guide provides systematic analysis of the UN thread system, detailed examination of UNC and UNF thread specifications, comparative evaluation of their technical differences, and practical selection guidelines based on ANSI/ASME B1.1 standards, global usage patterns, and emerging manufacturing trends.

UN Thread System Overview: Foundation of American Thread Standards

Historical Development and Standardization

The Unified Thread Standard (UN) originated from collaborative efforts between the United States, United Kingdom, and Canada during the early 20th century to resolve thread specification inconsistencies that hampered military cooperation and international trade. In 1948, ANSI (American National Standards Institute) and ASME (American Society of Mechanical Engineers) jointly published the ANSI/ASME B1.1 standard, formally establishing the UN thread system with comprehensive specifications for thread form, pitch series, tolerance grades, and designation methods.

The UN system features a unified 60-degree thread angle with rounded roots and crests (flat crests for some coarse threads) that reduce stress concentration and improve fatigue strength compared to earlier American National Thread (NC/NF) standards. The comprehensive pitch series ranging from coarse to extra-fine threads addresses diverse connection requirements across industries.

UN Thread Series Classification

The UN thread system comprises four primary series distinguished by pitch density:

- UNC (Unified National Coarse Thread): Largest pitch, lowest threads per inch (TPI), most widely used for general purpose applications

- UNF (Unified National Fine Thread): Smaller pitch, higher TPI, superior vibration resistance for precision applications

- UNEF (Unified National Extra Fine Thread): Extremely fine pitch for thin-walled components and precision instruments

- UNS (Unified National Special Thread): Non-standard pitches for specialized applications and legacy equipment

Comparison with ISO Metric Thread System

The global thread standard landscape divides primarily between UN (inch-based) and ISO Metric (millimeter-based) systems with significant incompatibilities:

| Comparison Aspect | UN Thread System (UNC/UNF) | ISO Metric Thread System |

|---|---|---|

| Unit System | Inch-based (diameter in inches, pitch as TPI) | Millimeter-based (diameter in mm, pitch in mm) |

| Thread Form | 60° angle with specified root/crest radii | 60° angle with different root/crest specifications |

| Tolerance System | Class 1A/2A/3A (external), 1B/2B/3B (internal) | 4h/6h/8h (external), 4H/5H/6H/7H (internal) |

| Geographic Prevalence | North America, aerospace, certain automotive sectors | Europe, Asia, global general manufacturing |

| Interchangeability | Not directly interchangeable; adapter fittings required | |

UNC Threads (Unified National Coarse Thread)

Definition and Core Characteristics

UNC threads feature the largest pitch (lowest TPI) in the UN system, designed specifically for rapid assembly, manufacturing efficiency, and reliability in non-precision applications. The coarse pitch design provides thicker thread walls, shallower thread depth (relative to diameter), and reduced material removal during manufacturing.

Key advantages include excellent resistance to thread stripping due to robust thread form, tolerance for misalignment during assembly, and maintained functionality in contaminated environments. UNC threads demonstrate superior performance in high-tensile applications and withstand repeated disassembly with minimal wear degradation.

Common Specifications and Technical Parameters

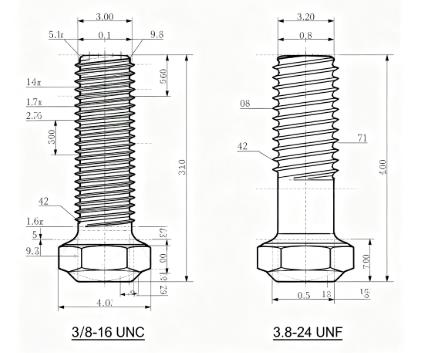

UNC thread designation follows the format "Nominal Diameter (inches)-Threads Per Inch-UNC-Tolerance Class" (tolerance class optional, default 2A/2B):

| Nominal Diameter | UNC Specification | Pitch (mm) | Minor Diameter (External, mm) | Major Diameter (Internal, mm) |

|---|---|---|---|---|

| 1/4 inch | 1/4-20 UNC | 1.270 | 5.189 | 6.571 |

| 3/8 inch | 3/8-16 UNC | 1.588 | 8.156 | 9.835 |

| 1/2 inch | 1/2-13 UNC | 1.954 | 10.632 | 13.017 |

| 5/8 inch | 5/8-11 UNC | 2.309 | 13.572 | 16.202 |

| 3/4 inch | 3/4-10 UNC | 2.540 | 16.299 | 19.145 |

Advantages and Limitations

Advantages:

- Rapid assembly with fewer turns required for engagement

- Reduced manufacturing cost due to faster machining and longer tool life

- Superior resistance to cross-threading and damage during assembly

- Excellent performance in high-tensile and impact loading conditions

- Maintained functionality with minor contamination or damage

Limitations:

- Reduced vibration resistance requiring additional locking mechanisms

- Lower fatigue strength under cyclic loading conditions

- Poor sealing capability for fluid applications

- Unsuitable for thin-walled components due to deep thread engagement

- Lower positional accuracy for precision alignment applications

Typical Application Areas

- Automotive Industry: Chassis components, wheel fasteners, structural frame connections

- General Machinery: Equipment bases, motor mounts, machinery housings

- Construction Engineering: Structural steel connections, scaffolding, heavy equipment

- Consumer Products: Furniture assembly, appliance manufacturing, general hardware

UNF Threads (Unified National Fine Thread)

Definition and Core Characteristics

UNF threads feature finer pitch (higher TPI) than UNC threads, designed specifically for applications requiring precision alignment, vibration resistance, and enhanced fatigue performance. The fine pitch configuration provides greater thread engagement area, more uniform load distribution, and superior resistance to loosening under vibrational forces.

Key advantages include improved fatigue life (20-40% longer than equivalent UNC threads), reduced necessity for auxiliary locking devices, better sealing characteristics, and suitability for thin-walled components and precision instruments. UNF threads demonstrate optimal performance in high-vibration environments and precision mechanical systems.

Common Specifications and Technical Parameters

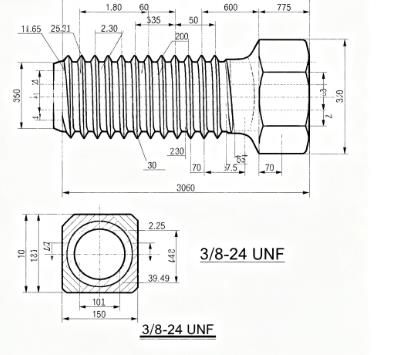

UNF thread designation follows the format "Nominal Diameter (inches)-Threads Per Inch-UNF-Tolerance Class":

| Nominal Diameter | UNF Specification | Pitch (mm) | Minor Diameter (External, mm) | Major Diameter (Internal, mm) |

|---|---|---|---|---|

| 1/4 inch | 1/4-28 UNF | 0.907 | 5.563 | 6.451 |

| 3/8 inch | 3/8-24 UNF | 1.058 | 8.740 | 9.728 |

| 1/2 inch | 1/2-20 UNF | 1.270 | 11.355 | 12.903 |

| 5/8 inch | 5/8-18 UNF | 1.411 | 14.324 | 16.084 |

| 3/4 inch | 3/4-16 UNF | 1.588 | 16.562 | 18.618 |

Advantages and Limitations

Advantages:

- Superior vibration resistance and anti-loosening characteristics

- Enhanced fatigue strength and longer service life under cyclic loading

- Better sealing capability for fluid and gas applications

- Higher positional accuracy for precision alignment requirements

- Optimal performance in thin-walled component applications

Limitations:

- Higher manufacturing cost due to precision machining requirements

- Increased susceptibility to thread damage during assembly

- Reduced performance with repeated disassembly and reassembly

- Longer assembly time due to increased turns required for engagement

- Reduced tolerance for contamination during assembly

Typical Application Areas

- Aerospace Industry: Aircraft structures, engine components, hydraulic systems

- Precision Instruments: Optical equipment, measuring devices, scientific instruments

- High-Performance Automotive: Engine components, transmission systems, suspension

- Hydraulic/Pneumatic Systems: Fluid power components, pressure vessels, valve connections

UNC vs UNF: Comprehensive Technical Comparison

Pitch and Thread Count Analysis

The fundamental difference between UNC and UNF threads lies in their pitch characteristics. For identical nominal diameters, UNF threads have significantly higher thread counts (TPI) and correspondingly smaller pitches:

| Nominal Diameter | UNC Threads Per Inch | UNC Pitch (mm) | UNF Threads Per Inch | UNF Pitch (mm) | Pitch Reduction |

|---|---|---|---|---|---|

| 1/4 inch | 20 | 1.270 | 28 | 0.907 | 28.6% |

| 3/8 inch | 16 | 1.588 | 24 | 1.058 | 33.4% |

| 1/2 inch | 13 | 1.954 | 20 | 1.270 | 35.0% |

| 5/8 inch | 11 | 2.309 | 18 | 1.411 | 38.9% |

| 3/4 inch | 10 | 2.540 | 16 | 1.588 | 37.5% |

Strength and Load Capacity Comparison

Static Load Capacity: Under pure tensile loading, UNC and UNF threads of identical diameter and material exhibit similar ultimate strength, as static capacity depends primarily on root diameter and material properties. UNC threads demonstrate marginally better impact resistance (5-10% improvement) due to thicker thread walls.

Fatigue Load Capacity: UNF threads significantly outperform UNC threads under cyclic loading conditions. The finer pitch distributes loads across more thread engagements, reducing stress concentration and improving fatigue life by 20-40% based on ANSI/ASME B1.1 testing data.

Application Scenario Comparison

| Application Requirement | Recommended Thread Type | Technical Rationale |

|---|---|---|

| General purpose fastening | UNC | Cost-effective, rapid assembly, sufficient for most non-critical applications |

| High-vibration environments | UNF | Superior resistance to vibrational loosening, reduced need for locking devices |

| Thin-walled components | UNF | Reduced material displacement, better stress distribution in thin sections |

| Precision alignment applications | UNF | Finer adjustment capability, better positional accuracy |

| Frequent disassembly requirements | UNC | Robust thread form withstands repeated assembly/disassembly cycles |

| High-pressure sealing applications | UNF | Longer leak path, better sealing characteristics |

| High-volume production | UNC | Lower manufacturing cost, faster production cycles |

| Impact loading conditions | UNC | Superior resistance to thread deformation under shock loads |

Designation Standards Comparison

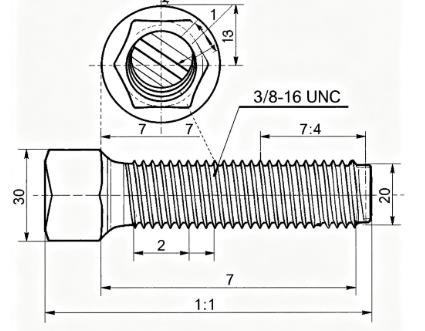

Both UNC and UNF threads follow standardized designation formats, but careful attention to series identification is critical to prevent misapplication:

UNC Designation Examples:

- 1/4-20 UNC (external thread, default Class 2A tolerance)

- 1/2-13 UNC-2B (internal thread, specified Class 2B tolerance)

UNF Designation Examples:

- 3/8-24 UNF (external thread, default Class 2A tolerance)

- 1/4-28 UNF-2B (internal thread, specified Class 2B tolerance)

Comprehensive Comparison Table

| Comparison Parameter | UNC Threads | UNF Threads |

|---|---|---|

| Pitch (threads per inch) | Lower TPI, coarser pitch | Higher TPI, finer pitch |

| Thread wall thickness | Thicker, more robust | Thinner, more precise |

| Engagement area | Smaller contact area | Larger contact area |

| Assembly efficiency | Faster engagement | Slower engagement |

| Manufacturing cost | Lower cost | Higher cost |

| Vibration resistance | Lower, requires locking devices | Higher, often standalone |

| Fatigue life | Shorter service life | Longer service life |

| Component compatibility | Thick-walled sections | Thin-walled sections |

| Disassembly durability | Higher tolerance | Lower tolerance |

| Primary industries | Construction, general machinery, automotive chassis | Aerospace, precision instruments, hydraulic systems |

Standards and Inspection Methods

ANSI/ASME B1.1 Standard Requirements

The ANSI/ASME B1.1 standard governs the complete specification of UN threads, including UNC and UNF series. The current 2019 revision establishes comprehensive requirements for:

- Thread Form: 60-degree included angle, specified root and crest radii

- Tolerance Classes: Three primary classes (1, 2, 3) with Class 2 as standard for most applications

- Pitch Series: Complete specification of UNC, UNF, UNEF, and UNS thread series

- Material Specifications: Correlation with material strength grades per SAE, ASTM standards

Thread Inspection Methodology

Quality verification of UNC and UNF threads involves dimensional inspection and visual examination:

Dimensional Inspection:

- Thread Plug Gauges: GO/NOT-GO gauges for internal thread verification

- Thread Ring Gauges: GO/NOT-GO gauges for external thread verification

- Thread Micrometers: Precision measurement of pitch diameter

- Optical Comparators: Profile verification for critical applications

Visual Inspection:

- Surface finish evaluation

- Detection of burrs, chips, or surface defects

- Verification of proper thread form

Compatibility with ISO Metric System

UNC/UNF threads are not interchangeable with ISO metric threads despite similar appearance. Critical differences include:

- Different measurement systems (inch vs metric)

- Different pitch specifications

- Different tolerance systems

- Different thread form specifications

Conversion between systems requires dedicated adapter fittings or custom-designed fasteners with hybrid threading.

Global Application Patterns

North American Dominance

United States and Canada represent the primary markets for UNC/UNF threads with near-universal adoption across industries:

- Automotive: Domestic manufacturers (Ford, GM, Chrysler) use UNC/UNF exclusively

- Aerospace: Boeing, Lockheed Martin utilize UNF threads for critical applications

- General Manufacturing: Over 90% of industrial equipment employs UN thread system

European Adaptation

Europe maintains ISO metric as primary standard with UNC/UNF usage in specific sectors:

- Aerospace: Airbus incorporates UNF threads for compatibility with US components

- Automotive: European manufacturers produce US-specific models with UNC/UNF threads

- Specialized Equipment: US-origin machinery maintenance requires UNC/UNF fasteners

Asian Manufacturing Landscape

Asian countries primarily utilize ISO metric system with UNC/UNF production for export markets:

- China: Major exporter of UNC/UNF components for North American market

- Japan: Precision UNF thread manufacturing for aerospace and automotive exports

- India: Growing production of UNC threads for agricultural equipment exports

Global Supply Chain Considerations

Multinational corporations implement thread strategy based on destination markets:

- North American products utilize UNC/UNF threads exclusively

- Global products may incorporate dual-standard components

- Suppliers must maintain capability for both thread systems

Selection Methodology and Application Guidelines

Four-Step Selection Process

Step 1: Define Primary Application Requirements

- Prioritize UNC for cost-effective, rapid assembly applications

- Prioritize UNF for precision, vibration-resistant applications

Step 2: Analyze Component Characteristics

- Select UNF for thin-walled components (thickness < 5mm)

- Select UNC for thick-walled components (thickness > 10mm)

Step 3: Evaluate Loading and Maintenance Requirements

- Choose UNF for fatigue loading and high-vibration environments

- Choose UNC for static loading and frequent disassembly needs

Step 4: Consider Economic Factors

- Select UNC for high-volume production to minimize cost

- Consider UNF for low-volume precision applications

Application Case Studies

Case 1: Automotive Engine Cylinder Head

- Requirements: Vibration resistance, thermal cycling, sealing

- Selection: UNF threads (3/8-24 UNF)

- Rationale: Superior vibration resistance, better sealing

Case 2: Structural Steel Connection

- Requirements: High tensile strength, cost-effectiveness

- Selection: UNC threads (1/2-13 UNC)

- Rationale: Cost efficiency, adequate strength

Case 3: Aerospace Hydraulic Fitting

- Requirements: Vibration resistance, high-pressure sealing

- Selection: UNF threads (1/4-28 UNF)

- Rationale: Optimal vibration performance, superior sealing

Economic and Maintenance Considerations

Cost Factors:

- UNC threads reduce manufacturing cost by 30-50% in high-volume production

- UNF thread cost premium decreases in low-volume precision applications

Maintenance Factors:

- UNC threads withstand frequent disassembly with minimal degradation

- UNF threads require careful handling to prevent damage during maintenance

Future Trends and Technological Evolution

Digital Inspection Advancements

Traditional thread gauging is evolving toward digital methodologies:

- 3D Scanning: Non-contact measurement for complete thread profile verification

- In-Process Monitoring: Real-time quality control during manufacturing

- Digital Traceability: Comprehensive data logging for quality assurance

Standardization Trends

Global thread standards are experiencing convergence in specific sectors:

- Aerospace: Increasing adoption of UNF as global standard

- Automotive: Regional standards maintained with growing compatibility

- International Trade: Mutual recognition agreements between standards

Additive Manufacturing Applications

3D printing technology introduces new possibilities for thread manufacturing:

- Integrated Threading: Direct printing of UNC/UNF threads in components

- Customized Threads: Rapid production of special thread forms

- Material Optimization: Thread forms optimized for additive materials

Conclusion: Strategic Selection for Optimal Performance

UNC and UNF threads represent complementary solutions within the Unified Thread Standard, each optimized for specific application requirements. The selection decision fundamentally balances efficiency against precision, cost against performance.

UNC threads deliver superior value in general-purpose applications where cost-effectiveness, rapid assembly, and robust performance are paramount. UNF threads provide essential capabilities for precision applications demanding vibration resistance, fatigue performance, and reliable operation in demanding environments.

Engineering professionals must base thread selection on comprehensive analysis of operational requirements, component characteristics, loading conditions, and economic factors. Proper application of UNC and UNF thread standards ensures mechanical integrity, operational reliability, and cost-effective manufacturing across diverse industries and applications.

As manufacturing technology evolves, both UNC and UNF thread standards will continue to serve critical roles in global mechanical engineering, adapting to new materials, processes, and application requirements while maintaining the fundamental principles established in the ANSI/ASME B1.1 standard.