What is a Turn-Mill Compound Machine Tool?

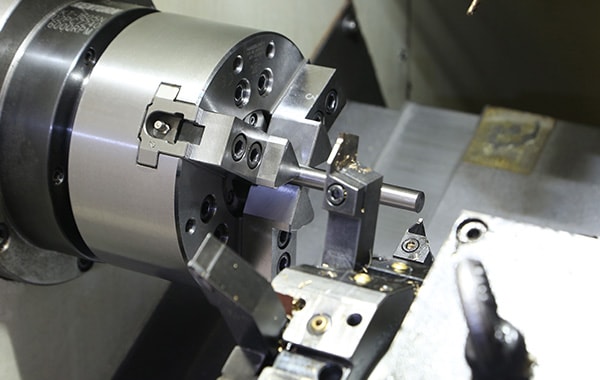

A turn-mill compound machine tool, as the name suggests, is a highly integrated machining center that cleverly combines the core rotational cutting capabilities of a CNC lathe with the multi-axis simultaneous machining and complex contouring functions of a CNC milling machine.

It allows multiple machining operations to be completed in a single setup, significantly improving machining efficiency and accuracy. Because it incorporates the versatile features of CNC turning, it reduces the machine footprint and lowers capital costs such as rent.

This compound integration is not a simple stacking of functions, but rather achieved through advanced design concepts and control technology. A single machine can perform turning, milling, drilling, tapping, boring, and even polygon turning with high precision.

Advantages of Turn-Mill Compound Machine Tools

1.High Precision: Eliminates errors caused by multiple setups across different machines. The turn-mill compound machine completes multiple operations in one setup, fundamentally reducing human and machine-induced inaccuracies.

2.High Efficiency: Effectively reduces production preparation time by eliminating the need for transferring, waiting, re-clamping, and re-aligning the workpiece between machines.

3.Cost Reduction: Sequentially completes multiple processes, reducing the number of machines required, simplifying production planning, and saving investment costs and factory floor space.

4.Versatile Integration: Combines the functions of CNC turning, milling, and polygon machining perfectly, enabling one-time completion of outer diameters, drilling, cutting off, polygon turning, and other operations.

5.Robust Structure: The machine bed and base are integrated castings, equipped with imported roller guides and ball screws, offering excellent vibration resistance and strong cutting forces.

6.Flexible Spindle Positioning: The turn-mill machine allows spindle positioning according to different product requirements and can machine polygons of any shape.

7.Standalone Lathe Mode: When milling or polygon machining is not required, the machine can fully function as a high-performance, high-precision CNC lathe. Its turning performance—including spindle rigidity, guideway and screw precision, and control system—is typically superior to ordinary CNC lathes, providing users with more flexible equipment options.

Rapid Model:

Because of these numerous advantages, and more importantly, because they meet the modern metalworking industry's demand for high efficiency, high profit, and low-cost machining, turn-mill compound machine tools are poised to advance to even higher levels driven by market demand.