Sandblasting brass can efficiently remove contaminants, optimize surface roughness, and create customized finishes such as matte or textured appearances. It also provides a solid foundation for subsequent processes like coating and welding. Compared with traditional methods such as mechanical polishing, sandblasting offers broader adaptability, adjustable parameters, and causes less damage to the base material.

Today, this technology has evolved from manual operations to intelligent digital control. Its value has extended beyond simple surface cleaning to achieving specialized functions such as biocompatibility and thermal radiation optimization, aligning with the trend of personalized customization.

This article will systematically explain the full-process technical essentials of brass sandblasting in 10 chapters, supplemented with relevant details, aiming to provide readers with a comprehensive reference.

Chapter 1: Brass Material Characteristics: The Fundamental Prerequisite for the Sandblasting Process

To achieve ideal brass sandblasting results, it is essential to first deeply understand the alloy composition and physicochemical properties of brass. Different brass compositions have significant differences in hardness and ductility, which directly determine key process parameters such as abrasive selection and pressure settings.

1.1 Brass Alloy Classification and Core Characteristics

Brass is not a single material but a general term for copper-zinc alloys. Depending on the zinc content and added elements, it can be divided into common brass and special brass. Their characteristic differences greatly influence the sandblasting process:

| Brass Type | Typical Grade | Zinc Content (%) | Hardness (HV) | Ductility | Main Application Scenarios | Key Points for Sandblasting Process |

|---|---|---|---|---|---|---|

| Common Brass (Low Zinc) | H90 | 10 | 65-80 | Extremely High | Precision instrument parts, decorative pieces | Requires mild abrasives (e.g., glass beads) to avoid deformation |

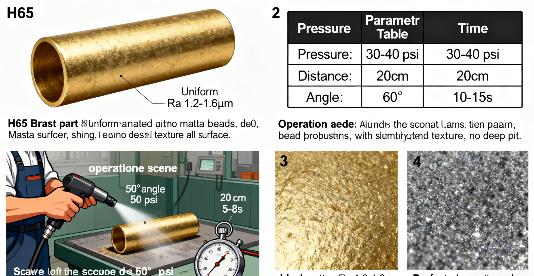

| Common Brass (Medium Zinc) | H65 | 35 | 100-120 | Medium | Automotive accessories, electronic connectors | Wide adaptability of abrasives and pressure, balancing efficiency and precision |

| Common Brass (High Zinc) | H59 | 41 | 130-150 | Relatively Low | Valves, pipe fittings and other structural components | Slightly harder abrasives (e.g., aluminum oxide) can be used to improve cleaning efficiency |

| Special Brass (Leaded) | HPb59-1 | 39-41 (Pb ~1) | 110-130 | Medium | Threaded parts, bearings | Need to control lead leaching after sandblasting, avoid abrasive residue |

| Special Brass (Tin-added) | HSn70-1 | 29-31 (Sn ~1) | 120-140 | Relatively High | Parts for seawater environments (e.g., ship components) | Requires enhanced passivation treatment after sandblasting to improve corrosion resistance |

Core Conclusion: Low-zinc brass (e.g., H90) is prone to surface indentation during sandblasting due to its extremely high ductility if pressure is too high; high-zinc or special brass (e.g., H59, HPb59-1) have higher hardness and can withstand slightly stronger abrasive impact, but attention must be paid to the characteristics of added elements (e.g., environmental risks of lead).

[Supplement: Influence of Material Microstructure on Sandblasting Response] Beyond macroscopic hardness and ductility, the microstructure of brass (such as grain size, phase composition) also affects the sandblasting result. Single-phase α-brass (e.g., H70) has a uniform solid solution structure, resulting in a uniform and fine texture after sandblasting. Whereas two-phase α+β brass (e.g., H59), due to the coexistence of α phase (soft) and β phase (hard), may experience minor selective etching during sandblasting, forming a richer micro-texture. Understanding this helps in material selection when pursuing specific aesthetic effects. Furthermore, cold-worked brass is harder than annealed brass, and its processing history needs to be considered when defining the process.

1.2 Common Brass Surface Problems and the Logic of Sandblasting Solutions

Untreated brass surfaces are prone to the following problems, for which sandblasting is one of the targeted solutions:

- Oxidation Layer: Brass easily forms an oxide film composed of Cu₂O and CuO in air, appearing dark brown and affecting appearance; sandblasting can directly strip the oxide layer through abrasive impact, exposing fresh metal surface.

- Machining Marks: Brass parts after CNC milling, stamping may retain tool marks, burrs; sandblasting can eliminate local protrusions through uniform abrasive action, making surface roughness consistent.

- Oil Stains and Impurities: Cutting fluid used during processing, fingerprint residue can affect the adhesion of subsequent coatings; pre-treatment before sandblasting (combined with degreasing) can thoroughly remove oil stains, while sandblasting itself can further clean surface crevices.

- Appearance Homogenization: The mirror effect of pure brass is aesthetically pleasing, but textured appearances are needed in decorative and anti-slip scenarios; sandblasting can create diverse surface effects from fine matte to coarse texture by selecting different abrasives.

[Supplement: Logic of Combining Sandblasting with Other Surface Treatment Technologies] Sandblasting is not an isolated step; it is often used in combination with other technologies. For example:

* Sandblasting + Chemical Polishing/Electropolishing: Sandblasting provides a uniform matte substrate, subsequent polishing can produce a unique 'matte with brightness' layered effect on this base.

* Sandblasting + Brushing: First sandblast to obtain a uniform base color, then create directional textures through brushing, adding design sense.

* Sandblasting + PVD (Physical Vapor Deposition): The rough surface formed by sandblasting greatly improves the adhesion of PVD coatings, making it a standard pre-treatment process for high-end decorative parts (e.g., black titanium brass).

This combinatorial thinking greatly expands the artistic and functional boundaries of brass surface treatment.

Chapter 2: Sandblasting Technology Fundamentals: Principles, Classification, and Core Parameters

The essence of sandblasting is a physical process of "kinetic energy of abrasives acting on the substrate surface". Its effect is determined by three factors: abrasive characteristics, equipment type, and process parameters. Understanding the basic theory of sandblasting is a prerequisite for achieving precise brass treatment.

2.1 Core Principles and Classification of Sandblasting

Sandblasting uses a "power source to drive abrasives" to form a high-speed jet. When the jet impacts the brass surface, it produces three effects: "cutting, impacting, and grinding":

- Cutting Action: The edges of sharp abrasives (e.g., aluminum oxide) perform micro-cutting on the surface, removing oxide layers or machining marks.

- Impact Action: High-speed impact of spherical abrasives (e.g., glass beads) causes plastic deformation on the surface, forming a matte texture.

- Grinding Action: The friction of irregular abrasives (e.g., walnut shells) refines surface roughness.

Depending on the power source and process characteristics, brass sandblasting can be classified into the following types:

| Sandblasting Type | Power Source | Abrasive Feed Method | Advantages | Disadvantages | Suitable Brass Scenarios |

|---|---|---|---|---|---|

| Compressed Air Sandblasting | Compressed Air | Pressure Pot / Suction Feed | Wide adjustable pressure range (0-100 psi), suitable for fine parts | Requires compressed air system, high energy consumption; significant abrasive splash | Small/medium CNC parts, decorative pieces |

| Centrifugal Blasting | High-speed Rotating Wheel | Centrifugal Throw | No air pressure limit, high abrasive utilization (>80%) | Poor pressure uniformity, not suitable for complex curves | Large brass sheets, simple structural parts |

| Wet Blasting / Vapor Blasting | High-pressure water stream (containing abrasive) | High-pressure pump delivery | No dust pollution, suitable for heavily oil-contaminated parts | Requires drying post-treatment to avoid brass rusting | Brass pipes, valves with heavy oil residue |

| Robotic Automated Blasting | Robot Arm + Compressed Air | Precision positioned feed | High repeatability precision (±0.1mm), suitable for complex parts | High equipment investment, high cost for small batches | Mass-produced precision CNC parts (e.g., connectors) |

[Supplement: Special Note on Wet Blasting] Wet blasting (or liquid honing) holds unique value in brass treatment. By mixing abrasive with a water stream before blasting, it effectively suppresses dust, reduces workpiece temperature, and decreases the impact stress of abrasives on the workpiece, making it very suitable for high-precision, thin-walled, or finely finished brass parts. Simultaneously, the water stream also cleans, potentially completing blasting and cleaning in one step. Its drawbacks are more complex equipment, the need for immediate drying after blasting to prevent oxidation, and more troublesome abrasive recovery compared to dry blasting.

2.2 Core Process Parameters and Influence Patterns

The effect of brass sandblasting (surface roughness Ra, texture uniformity, material removal rate) is determined by five core parameters. Understanding their interaction is key to process optimization:

| Process Parameter | Definition | Impact on Brass Sandblasting | Typical Adjustable Range (for Brass) |

|---|---|---|---|

| Blasting Pressure | Pressure of the abrasive jet (psi) | Higher pressure increases material removal rate but can easily deform low-zinc brass; too low pressure leads to incomplete cleaning. | 20-80 psi (H90: 20-40 psi; H59: 40-80 psi) |

| Abrasive Grit Size | Particle size of the abrasive (Mesh) | Higher mesh number (finer particles) results in smoother surface (Ra 0.8-1.6μm); Lower mesh number (coarser particles) creates deeper texture (Ra 3.2-6.3μm). | 60-200 Mesh (Decorative: 120-200 Mesh; Structural: 60-120 Mesh) |

| Blast Distance | Distance from nozzle to brass surface (cm) | Too close (<10cm): local impact too strong, prone to pitting; Too far (>30cm): abrasive kinetic energy decays, uneven effect. | 15-25 cm (Complex parts: 20-25 cm; Simple parts: 15-20 cm) |

| Blast Angle | Angle between nozzle axis and surface (°) | 90° (perpendicular): highest cleaning efficiency, but can cause indentation; 45°-60° (angled): more uniform texture, suitable for fine parts. | 45°-90° (Flat surfaces: 90°; Curved surfaces: 45°-60°) |

| Blast Time | Duration of blasting on the same area (s) | Longer time removes more material, but over-blasting leads to dimensional deviation; too short time results in uneven surface. | 5-30 s (Thin oxide: 5-10 s; Heavy machining marks: 20-30 s) |

Parameter Synergy Rule: For example, when treating H65 brass decorative parts, if using 80 mesh glass beads, parameters like 30-40 psi pressure, 20 cm distance, 60° angle, and 10-15 s blast time can achieve a uniform matte effect with Ra 1.2-1.6μm. If pressure is increased to 50 psi, time should be reduced to 5-8 s to avoid an overly rough surface.

[Supplement: Interaction of Parameters and Mathematical Modeling] Process parameters do not act independently but have complex interactive effects. For instance, increasing pressure can, to some extent, compensate for the reduced cutting force associated with finer abrasive grit. Advanced sandblasting process development is beginning to incorporate Design of Experiments (DOE) methods, establishing approximate mathematical models between parameters (e.g., Pressure P, Grit G, Time T) and results (e.g., Roughness Ra) (for example: Ra = k * P^a * G^b * T^c), enabling accurate prediction and optimization of surface outcomes. This is crucial for automated production.

Chapter 3: Pre-Treatment for Brass Sandblasting: Full Process Control from Cleaning to Inspection

The surface condition before sandblasting directly determines the final result. If surface contaminants like oil, oxide, or impurities remain, abrasives will preferentially impact the contaminants, leading to uneven blasting. If the substrate has minor defects (e.g., cracks), they may enlarge during sandblasting without pre-treatment. Therefore, pre-treatment should follow a "Clean -> Repair -> Inspect" process.

3.1 Surface Cleaning: Targeted Removal of Contaminants

Contaminants on brass surfaces mainly include oil/grease, oxide layers, and machining debris, requiring suitable cleaning methods:

3.1.1 Oil/Grease Removal: Selecting Solutions by Scenario

Sources of oil include cutting fluid, anti-rust oil, fingerprints. Comparison of removal methods:

- Solvent Degreasing: Use alcohol, acetone, or specialized metal degreasers (e.g., eco-friendly hydrocarbon solvents), via wiping or immersion (10-15 min). Advantage: fast, suitable for small batches. Disadvantage: solvents evaporate easily, requiring ventilation protection.

- Chemical Degreasing (Alkaline): Use alkaline degreaser (e.g., 5%-8% sodium hydroxide solution, temperature 50-60°C), immerse for 20-30 min. Advantage: low cost, suitable for large batches. Disadvantage: requires subsequent rinsing (to avoid residual alkali corrosion of brass).

- Ultrasonic Cleaning: Place parts in ultrasonic cleaner (frequency 28-40 kHz) with neutral detergent, clean for 15-20 min. Advantage: penetrates threaded holes, crevices, suitable for complex CNC parts. Disadvantage: higher equipment investment.

Note: After degreasing, rinse 2-3 times with deionized water, then dry with hot air (60-80°C) to avoid residual moisture causing secondary oxidation.

[Supplement: Rapid Cleanliness Verification Methods] Besides white lint-free cloth wiping and contact angle measurement, a commonly used quick verification method in production is the "Water Break Test". Immerse the cleaned brass part in pure water, then withdraw it vertically, observing the surface water film. If a continuous, unbroken water film forms and slowly breaks, cleanliness is good. If the water film immediately breaks into droplets, oil contamination is likely still present. This method is simple, effective, and suitable for quick on-site judgment.

3.1.2 Oxide Layer Removal: Based on Oxidation Severity

Light oxidation (surface darkening) can be removed directly by sandblasting, but severe oxidation (oxide layer thickness > 5μm, black or gray) requires pre-treatment:

- Acid Pickling: Use 10%-15% sulfuric acid solution (temperature 20-30°C), immerse for 5-10 min; or use specialized brass pickling paste (apply and let sit for 8-12 min). After pickling, immediately rinse with deionized water and neutralize with 3%-5% sodium carbonate solution to prevent acid residue.

- Mechanical Grinding: For localized severe oxidation, manually grind with 400-600 grit sandpaper to remove thick oxide layer before sandblasting; avoid coarse sandpaper (<300 grit) to prevent leaving grind marks.

3.1.3 Machining Debris Removal

Brass parts after CNC machining (e.g., drilled, milled) easily retain metal chips, requiring cleanup by:

- Compressed Air Blowing: Use 0.4-0.6 MPa compressed air with a fine nozzle to blow out threaded holes, blind holes, etc.

- High-Pressure Water Rinsing: For parts without sealing requirements, rinse with 0.8-1.0 MPa high-pressure water to remove debris from crevices.

- Magnetic Separation: For parts with magnetic impurities (e.g., from contact with carbon steel tools), use a magnet to adsorb surface iron chips.

3.2 Surface Repair: Pre-Treating Substrate Defects

Sandblasting cannot repair structural defects in brass; these must be addressed in the pre-treatment stage:

- Deburring: For burrs from stamping, milling, manually trim with a deburring tool or grinding wheel (800 grit), or use a vibratory finisher (with resin media) for 1-2 hours.

- Micro-Crack Detection: For stressed parts (e.g., brass bearings), use penetrant inspection (e.g., red dye penetrant + white developer) to detect surface cracks. If found, repair (e.g., welding) before sandblasting.

- Dimensional Calibration: For precision parts, measure key dimensions with micrometers, calipers to ensure errors are within tolerance (sandblasting removes 0.01-0.03mm of material, requiring allowance).

3.3 Surface Inspection: Ensuring Pre-Treatment Quality Meets Standards

After pre-treatment, the brass surface must meet the following inspection standards before proceeding to sandblasting:

- Cleanliness Inspection: Wipe surface with white lint-free cloth, cloth should be free of oil/stains; or use contact angle measurer, water contact angle < 30° indicates oil-free surface.

- Oxide Layer Inspection: Visual inspection shows no dark spots, black areas; or use eddy current thickness gauge to measure oxide layer thickness, should be < 1μm.

- Defect Inspection: Visual or magnifying glass (10-20x) inspection shows no burrs, cracks, dents, etc.

[Supplement: Balancing Environmental Concerns and Cost in Pre-Treatment] When selecting pre-treatment processes, environmental regulations and cost must be considered together. For example, while solvent degreasing is fast, VOC emissions are restricted; alkaline degreasing is low cost but requires wastewater treatment investment. Ultrasonic cleaning, though expensive equipment-wise, often uses neutral or eco-friendly detergents, offering good overall environmental benefits. Companies should determine the optimal pre-treatment plan based on their scale and local environmental regulations.

Chapter 4: Abrasives for Brass Sandblasting: Scientific Decision-Making from Characteristics to Selection

Abrasives are the "tools" of brass sandblasting. Their hardness, shape, and composition directly determine the surface effect and the degree of substrate damage. Abrasive selection should follow the principle of "matching brass type + meeting surface requirements + considering cost and environmental impact".

4.1 Characteristics and Application Scenarios of Common Abrasives

Abrasives for brass sandblasting should avoid excessive hardness (e.g., silicon carbide, HV 2800) to prevent over-cutting. Common abrasives sorted by increasing hardness:

| Abrasive Type | Main Composition | Hardness (HV) | Shape | Surface Effect | Suitable Brass Types & Scenarios | Cost (USD/kg) | Environmental Friendliness |

|---|---|---|---|---|---|---|---|

| Walnut Shell Grit | Processed Crushed Walnut Shells | 30-50 | Irregular Particles | Fine Matte (Ra 0.8-1.2μm) | H90, H65 precision parts (instrument panels), decorative pieces | 1.2-1.8 | Biodegradable, low dust |

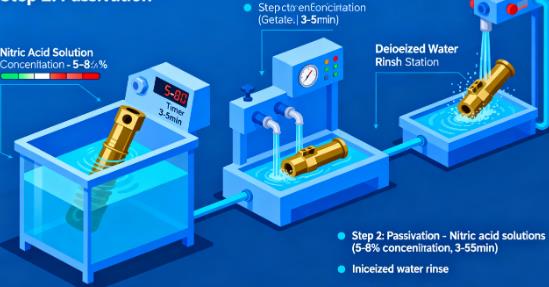

| Glass Beads | Soda-Lime Glass | 450-550 | Spherical | Uniform Matte (Ra 1.2-1.6μm) | All brass types, especially CNC parts requiring detail preservation | 0.9-1.5 | Recyclable (3-5 cycles) |

| Aluminum Oxide (White Fused Alumina) | Al₂O₃ | 1800-2000 | Angular | Medium-Coarse Texture (Ra 1.6-3.2μm) | H59, HPb59-1 structural parts (valves, pipe fittings) | 0.6-1.2 | Dust requires collection |

| Steel Grit | High Carbon Steel | 800-1000 | Multi-angular | Coarse Texture (Ra 3.2-6.3μm) | Brass wear parts (bearing housings), requiring enhanced slip resistance | 0.75-1.35 | Recyclable (requires screening) |

| Sodium Bicarbonate (Baking Soda) | NaHCO₃ | 20-30 | Powdery | Ultra-Fine Matte (Ra 0.4-0.8μm) | Brass pre-treatment before plating, sensitive electronic parts | 1.5-2.3 | Water-soluble, no residue |

Key Comparison: For example, for a brass door handle (H65), if a high-end matte finish is needed, choose 120 mesh glass beads; for low cost and eco-friendliness, choose 100 mesh walnut shell; if preparing for painting (enhancing adhesion), choose 80 mesh aluminum oxide.

[Supplement: New and Composite Abrasives] To meet higher demands, new and composite abrasives have emerged:

* Ceramic Composite Abrasives: Sintered composites of zirconia, alumina, etc. Moderate hardness (HV 700-900), good toughness, low wear rate, lifespan much longer than glass beads and alumina, enabling very stable surface quality. Although unit cost is higher, long-term comprehensive cost may be lower.

* Spherical Stainless Steel Shot: More durable than glass beads, with no risk of破碎 contamination, suitable for brass parts requiring极高 cleanliness in medical, food fields.

* Composite Plastic Media: Plastic carrier impregnated with abrasive grains (e.g., silicon carbide), combines plastic deformation and cutting, minimal substrate damage, suitable for ultra-precision brass parts.

These abrasives offer more options for brass sandblasting.

|

|

Walnut Shell Grit |

Aluminum Oxide |

4.2 Four Core Dimensions for Abrasive Selection

- Hardness Matching: Abrasive hardness should preferably be less than 1.5 times the brass hardness (e.g., H65 hardness HV 100-120, abrasive hardness < 180 HV) to avoid over-cutting; only high-zinc brass (H59, HV 130-150) can use aluminum oxide (HV 1800), but pressure and time must be controlled.

- Grit Size Selection: Determined based on required surface roughness. Rough guideline: increasing mesh by 40 reduces Ra by about 0.4μm (e.g., 80 mesh glass beads Ra ~1.6μm, 120 mesh ~Ra 1.2μm).

- Shape Influence: Spherical abrasives (glass beads) impact uniformly, suitable for fine surfaces; Angular abrasives (aluminum oxide) have strong cutting force, suitable for cleaning or texturing; Irregular abrasives (walnut shell) have weak friction, suitable for sensitive parts.

- Cost and Recyclability: Glass beads, steel grit can be recycled (requires screening to remove fines), low cost per use; Walnut shell, baking soda are single-use, suitable for small batches or high eco-requirement scenarios.

4.3 Abrasive Pre-Treatment and Usage Notes

- Pre-Treatment: New abrasive should be screened to remove impurities and fines, preventing nozzle clogging; Recycled abrasive should be magnetically separated to remove iron chips (especially steel grit), preventing contamination of brass surface.

- Moisture Control: Abrasive moisture content should be < 5%, otherwise prone to clumping (e.g., glass beads) or失效 (e.g., baking soda absorbs moisture); store sealed with desiccant.

- Consumption Calculation: For batch blasting, abrasive consumption can be estimated: Consumption (kg) = Part Surface Area (m²) × Abrasive Consumption Factor (0.2-0.5 kg/m², use lower value for fine abrasives, higher for coarse).

[Supplement: Abrasive Life Management and Economic Analysis] Establishing an abrasive life management system is crucial. Record the number of cycles and performance of each abrasive type used on different equipment and brass parts. Set clear报废 criteria (e.g., change in particle size distribution beyond a limit, breakage rate exceeding a threshold). By calculating the cost per treatment (abrasive purchase cost / cycles + screening energy cost), more scientific decisions regarding abrasive selection and replacement can be made, optimizing economics.

Chapter 5: Brass Sandblasting Equipment: Full Lifecycle Management from Selection to Maintenance

Sandblasting equipment is the carrier for process implementation. Its type, precision, and stability directly affect the efficiency and consistency of brass sandblasting. Equipment selection should consider production scale, part complexity, and automation needs, while emphasizing daily maintenance to extend service life.

5.1 Equipment Types and Applicable Scenarios

Based on production needs, brass sandblasting equipment can be classified into manual, semi-automatic, and fully automatic:

| Equipment Type | Core Components | Production Rate (parts/hour, small) | Suitable Part Types | Equipment Investment (k USD, approx.) | Advantages | Disadvantages |

|---|---|---|---|---|---|---|

| Manual Blast Cabinet | Pressure Pot (50-100L), Handheld Nozzle | 10-30 | Prototypes, small batches of complex parts (odd-shaped decorative pieces) | 1.5-4.5 | High flexibility, suitable for multi-variety small batch | Low efficiency, depends on operator skill |

| Semi-Auto Table Blaster | Rotating Table (Dia. 1-2m), Fixed Nozzles | 50-100 | Batch standardized parts (e.g., brass connectors) | 7-15 | Medium efficiency, consistency better than manual | Requires manual loading/unloading, not for very large parts |

| Fully Automatic Robot Blaster | Robot (4-6 axis), Enclosed Blast Room | 100-300 | Large batches of precision parts (e.g., automotive brass fittings) | 30-75 | High precision (repeatability ±0.1mm), high efficiency | High investment, long changeover (reprogramming needed) |

| Continuous Pass-Through Blaster | Conveyor, Multiple Nozzle Banks | 10-20 m/min (sheets) | Brass sheets, long parts (e.g., handles) | 12-22 | Continuous production, suitable for long parts | Not suitable for complex curved parts |

5.2 Key Component Selection and Parameters

- Nozzle:

- Material: Choose boron carbide (wear-resistant, life ~800-1000 hours) or sapphire (high precision, life ~1500-2000 hours); avoid common ceramics (prone to wear causing pressure fluctuations).

- Orifice: Select based on abrasive grit, e.g., 80-120 mesh suits φ6-8mm nozzle, 150-200 mesh suits φ4-6mm nozzle.

- Pressure Pot:

- Volume: Small batch: 50-100L, Large batch: 200-500L.

- Pressure Control: Equip with precision pressure regulator (accuracy ±1 psi) to ensure stable pressure.

- Blast Cabinet/Room:

- Material: Line interior with rubber lining (impact resistant, easy to clean abrasives).

- Ventilation System: Equip with pulse-jet baghouse dust collector (filtration efficiency > 99%), ensuring indoor dust concentration < 10 mg/m³ (meets OSHA/ACGIH standards).

- Automation System:

- Robot: Select 6-axis robot with 5-10 kg payload (e.g., Fanuc LR Mate 200iD), repeatability ±0.02mm.

- Positioning Fixture: Use brass-specific fixtures (to avoid scratches), e.g., silicone vacuum cups, V-blocks, ensuring secure part holding.

5.3 Equipment Daily Maintenance and Troubleshooting

5.3.1 Daily Maintenance Schedule and Content

Maintenance Frequency Maintenance Tasks Daily 1. Check nozzle wear (replace if orifice enlarges > 0.5mm); 2. Clean dust collector filters; 3. Check pressure pot seals. Weekly 1. Lubricate robot joints (e.g., lithium grease); 2. Calibrate pressure regulator; 3. Check conveyor belt tension (pass-through systems). Monthly 1. Change hydraulic oil (pressure pot system); 2. Check electrical wiring insulation; 3. Clean accumulated dust inside equipment. Quarterly 1. Check robot repeatability accuracy; 2. Replace dust collector filter bags; 3. Inspect abrasive delivery hose wear. 5.3.2 Common Faults and Solutions

Fault Symptom Possible Cause Solution Blasting Pressure Fluctuation 1. Pressure pot seal leak; 2. Nozzle clog; 3. Unstable compressed air pressure. 1. Replace seal; 2. Clean nozzle (use fine wire); 3. Check compressor pressure, add pressure stabilizing valve. Uneven Surface Blasting 1. Inconsistent nozzle-to-part distance; 2. Uneven abrasive grit size; 3. Loose part fixture. 1. Adjust robot path (ensure distance error < 2cm); 2. Screen abrasive; 3. Optimize fixture design. Abrasive Feed Issues 1. High abrasive moisture (clumping); 2. Clogged delivery hose; 3. Insufficient air pressure in pot. 1. Dry abrasive; 2. Disassemble and clean hose; 3. Check compressor output pressure. Robot Positioning Deviation 1. Fixture wear; 2. Robot zero point drift; 3. Part dimension out of tolerance. 1. Replace fixture; 2. Recalibrate robot zero point; 3. Check part dimensions after pre-treatment. [Supplement: Equipment Energy Efficiency Management and Smart Upgrades] Sandblasting equipment, especially compressors, are significant energy consumers. Using frequency-controlled compressors and blasting equipment that adjust power based on actual demand can significantly reduce energy consumption. Furthermore, equipping devices with IoT modules to monitor compressor status, pressure pot curves, abrasive levels in real-time and upload data to a cloud platform for analysis enables predictive maintenance, avoiding unplanned downtime, and provides data for optimizing process parameters and reducing overall costs.

Chapter 6: Brass Sandblasting Process Optimization: Parameter Debugging and Defect Resolution

Even with suitable abrasives and equipment, improper parameter matching can still lead to issues like uneven surfaces or dimensional inaccuracies. Process optimization should follow the principle of "sample testing first, then batch production," achieving ideal results through systematic debugging.

6.1 Sample Testing: Determining Base Parameters

Sample testing is core to process optimization. Steps are as follows:

- Select Samples: Choose samples (recommend 3-5 pieces) identical to batch parts in material (e.g., H65), size, and surface condition.

- Define Parameter Sets: Use an "Orthogonal Array Testing" approach. Select 3-4 key parameters (e.g., Pressure, Grit, Distance), each with 3 levels, forming 9-12 parameter sets.

Example: For H65 brass decorative part, sets include (Pressure 30psi, 80 mesh Glass Beads, 20cm Distance), (Pressure 40psi, 100 mesh Glass Beads, 20cm Distance), etc. - Blast Testing: Blast samples according to each parameter set, mark with numbers.

- Effect Evaluation: Measure surface roughness (Ra), texture uniformity (visual + magnifier), dimensional change (micrometer) for each sample set. Screen for the optimal parameter combination.

6.2 Common Sandblasting Defects and Solutions

The following defects are prone to occur during brass sandblasting, requiring targeted process adjustments:

| Defect Type | Manifestation | Root Cause | Solution |

|---|---|---|---|

| Surface Pitting | Localized small dents (diameter 0.1-0.5mm) | 1. Pressure too high (>50 psi); 2. Nozzle distance too close (<15 cm); 3. Abrasive contains impurities (e.g., metal chips). | 1. Reduce pressure (e.g., from 50 psi to 35 psi); 2. Increase distance (e.g., from 15 cm to 20 cm); 3. Screen abrasive. |

| Oxide Residue | Local dark brown areas remain on surface | 1. Blast time too short; 2. Abrasive cutting force insufficient (e.g., walnut shell on heavy oxide); 3. Incorrect blast angle. | 1. Increase time (e.g., from 10 s to 15 s); 2. Change abrasive (e.g., walnut shell to aluminum oxide); 3. Adjust angle to 90°. |

| Dimensional Deviation | Key dimensions reduced (>0.03mm) | 1. Blast time too long; 2. Abrasive hardness too high; 3. Repeated blasting on same area. | 1. Shorten time (e.g., from 20 s to 10 s); 2. Change to softer abrasive (e.g., aluminum oxide to glass beads); 3. Optimize robot path to avoid overlap. |

| Surface Color Variation | Inconsistent glossiness in different areas | 1. Uneven abrasive grit size; 2. Pressure fluctuation; 3. Uneven surface cleanliness before blasting. | 1. Screen abrasive; 2. Install pressure stabilizer valve; 3. Enhance pre-cleaning (e.g., increase ultrasonic time). |

| Excessive Edge Rounding | Part edges become rounded (affects assembly) | 1. Nozzle angle too small (<45°); 2. Blast time on edges too long; 3. Insufficient fixture masking. | 1. Adjust angle to 60°-90°; 2. Reduce blast time on edges (e.g., from 10 s to 5 s); 3. Use silicone plugs to protect edges. |

6.3 Process Control for Batch Production

For batch production, establish a control system of "First-Article Inspection - In-Process Audit - Final-Piece Verification":

- First-Article Inspection: Before each shift, fully inspect the first part (Ra, dimensions, appearance) to confirm parameters are correct.

- In-Process Audit: Every 50-100 parts produced, randomly sample 1-2 parts for inspection. If defects found (e.g., Ra out of spec), stop immediately and adjust parameters.

- Final-Piece Verification: At the end of each shift, inspect the last part and compare with the first piece to confirm parameter stability.

- Data Recording: Maintain a process parameter log, recording pressure, abrasive grit, blast time, etc., for each shift to facilitate traceability.

[Supplement: Establishing a Process Parameter Database and Knowledge Base] Systematically record the successful parameters, material information, and inspection results from each sample test and batch production run into a database. Long-term accumulation forms the company's own "Brass Sandblasting Process Knowledge Base." This not only allows quick response to repeat orders but also provides valuable reference for new product development, significantly shortening process debugging cycles. Combining SPC (Statistical Process Control) methods to monitor and analyze key parameters (like Ra) in real-time enables closed-loop control and steady improvement of production quality.

Chapter 7: Post-Treatment for Brass Sandblasting: Quality Enhancement from Cleaning to Protection

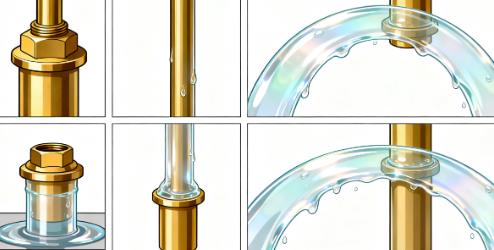

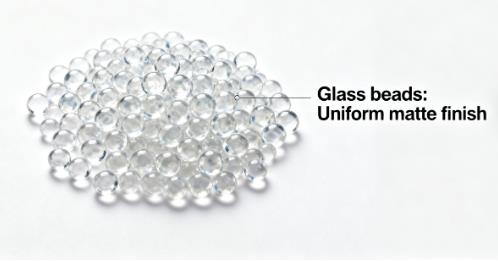

After sandblasting, the brass surface has the desired texture but still faces two issues: First, residual abrasive dust (e.g., broken glass bead fragments) remains on the surface. Second, the fresh metal surface is highly active and prone to oxidation (tarnishing within 1-2 hours of air exposure). Therefore, post-treatment is necessary to enhance the part's corrosion resistance and service life through a three-step process: "Cleaning -> Passivation -> Protection".

7.1 Post-Blast Cleaning: Thoroughly Removing Residual Contaminants

Cleaning after blasting must avoid damaging the surface texture. Common methods:

- Ultrasonic Cleaning: Place parts in ultrasonic cleaner (frequency 28 kHz) with neutral detergent (e.g., diluted dish soap), clean for 10-15 min, can remove fines from crevices.

- High-Pressure Water Rinse: For parts without sealing requirements, rinse with 0.3-0.5 MPa high-pressure water (with fan nozzle), avoid direct jet (to prevent texture distortion).

- Compressed Air Blow-off: For precision parts (e.g., electronic connectors), use 0.2-0.3 MPa compressed air (with fine nozzle) to blow out threaded holes, blind holes, removing residual fines.

- Drying: After cleaning, dry with hot air (60-80°C) or air dry naturally (avoid direct sunlight to prevent oxidation).

7.2 Surface Passivation: Enhancing Corrosion Resistance

After sandblasting, the highly active brass surface readily reacts with oxygen and moisture in the air to form an oxide layer. Passivation treatment is needed to create a protective film:

| Passivation Method | Process Parameters | Passivation Effect (Neutral Salt Spray Test) | Application Scenario | Precautions |

|---|---|---|---|---|

| Chromate Passivation | 5%-8% Sodium Chromate solution, temp 40-50°C, immerse 10-15 min | 72-120 hours no corrosion | Industrial structural parts (e.g., valves) | Chromates are toxic, require wastewater treatment (comply with regulations like EPA standards) |

| Chromium-Free Passivation | 3%-5% Zinc Phosphate solution, temp 50-60°C, immerse 15-20 min | 48-72 hours no corrosion | Decorative parts, food-contact parts | After passivation, need drying (80-100°C, 10 min) |

| Silane Passivation | 2%-3% Silane solution, room temp immerse 5-10 min | 36-48 hours no corrosion | Electronic parts (e.g., connectors) | Solution pH needs control (5-6) to avoid agglomeration |

Selection Advice: If high corrosion resistance is needed and no environmental restrictions, choose chromate passivation; if eco-friendly or food contact is required, choose chromium-free passivation; if enhancing coating adhesion (for subsequent painting) is the goal, choose silane passivation.

7.3 Surface Protection: Extending Appearance and Functional Life

Based on application, protection for sandblasted brass can be divided into "Coating Protection" and "Non-Coating Protection":

7.3.1 Coating Protection (For decorative parts, outdoor parts)

- Clear Coat (Lacquer/Varnish): Choose acrylic clear coat (air-dry, general weather resistance) or polyurethane clear coat (thermal cure, good weather resistance), applied by spraying (thickness 20-30μm) or dipping (15-20μm). Advantage: preserves matte texture, enhances corrosion resistance (salt spray can reach 120-200 hours).

- Metallic Coating: For parts requiring high corrosion resistance (e.g., marine brass fittings), electroplating (e.g., nickel, chrome) or thermal spray (e.g., aluminum coating) can be done after sandblasting, coating thickness 5-10μm.

- Powder Coating: For structural parts (e.g., brass handles), use epoxy resin powder coating (thickness 60-80μm), applied by electrostatic spray + thermal curing (180-200°C, 15-20 min), high impact resistance.

7.3.2 Non-Coating Protection (For precision parts, conductive parts)

- Anti-Rust Oil: For stored parts, apply a thin layer of anti-rust oil (e.g., ISO VG 10 oil), prevent oxidation; needs wiping off before use.

- Vapor Corrosion Inhibitor (VCI) Paper: Wrap parts with VCI paper, place in sealed packaging, protection period 6-12 months.

- Inert Gas Protection: For high-precision electronic parts, seal in packaging filled with nitrogen gas, completely isolating oxygen and moisture.

[Supplement: Development of Functional Post-Treatment Technologies] Post-treatment technologies are evolving towards functionality:

* Self-Healing Coatings: Incorporate microcapsule healing agents into clear coats. When fine scratches occur, capsules rupture releasing healing agent, automatically repairing the scratch.

* Chemical Coloring/Staining: Utilize the high activity of the sandblasted surface with chemical reagents to produce colored effects like antique bronze, verdigris, greatly enhancing artistic value.

* Superhydrophobic Coatings: Introduce nanomaterials during passivation or coating steps, giving the brass surface a lotus effect, making it water-repellent, anti-fouling, and anti-sticking.

These technologies赋予 brass products added value beyond traditional protection.

7.4 Post-Treatment Inspection: Ensuring Protective Effect

After post-treatment, parts should undergo the following inspections:

- Cleanliness Check: Wipe surface with white cloth, no abrasive dust, oil stains.

- Passivation Effect Check: Drop 5% copper sulfate solution on surface, no red spots within 30 seconds indicates intact passivation film.

- Coating Inspection: Use cross-cut test (ASTM D3359) for coating adhesion, should achieve highest rating (5B, no peeling); use eddy current thickness gauge for coating thickness, error ±5μm.

- Corrosion Resistance Check: Sample neutral salt spray test (ASTM B117), should meet design requirements (e.g., decorative parts ≥48 hours, structural parts ≥72 hours).

Chapter 8: Safety and Environmental Protection: Compliance Management for Brass Sandblasting

The brass sandblasting process involves three major safety hazards: dust pollution, noise hazards, and chemical risks, while also needing to comply with environmental regulations. Establishing a comprehensive safety and environmental system is both necessary for protecting operator health and a prerequisite for compliant production.

8.1 Safety Protection Measures

8.1.1 Personal Protective Equipment (PPE)

Operators must wear the following PPE, inspected and replaced regularly:

- Respiratory Protection: Wear dust respirator (NIOSH-approved N95/P100) or supplied-air respirator (if cabinet dust concentration > permissible exposure limit).

- Eye Protection: Wear impact-resistant safety goggles (ANSI Z87.1+), protect from flying abrasive.

- Body Protection: Wear durable protective clothing (e.g., canvas), safety shoes (steel toe), oil-resistant gloves (for degreasing).

- Hearing Protection: Blasting equipment noise typically 85-110 dB, wear earplugs (NRR ≥25 dB) or earmuffs (NRR ≥30 dB), compliant with relevant standards.

8.1.2 Work Area Safety Control

- Area Segregation: Isolate the blasting area from others, post warning signs (e.g., "PPE MUST BE WORN", "AUTHORIZED PERSONNEL ONLY").

- Ventilation Requirements: Blast room/cabinet must have mechanical ventilation, airflow velocity ≥0.5 m/s, ensuring indoor dust concentration < permissible exposure limit (e.g., OSHA PEL for nuisance dust).

- Fire Safety: Prohibit smoking in blasting area, provide dry chemical fire extinguishers (for abrasive dust fires), keep distance from open flames ≥10m.

- Emergency Facilities: Install eyewash station, emergency shower (located < 15m from blasting area) for use in case of chemical (e.g., pickling solution) splash on skin.

8.1.3 Equipment Safety Operation

- Pre-Job Training: Operators must be trained and certified before operating equipment, understanding operation, fault handling, emergency procedures.

- Pre-Startup Check: Before each operation, check equipment grounding (resistance < 4Ω), pressure pot safety valve (annual calibration), nozzle guard.

- Prohibit Violations: Never open pot lid before pressure is fully released; never point nozzle at people; never clean abrasives while equipment is running.

8.2 Environmental Compliance Management

The focus of environmental control in brass sandblasting is the treatment of dust, wastewater, and solid waste, complying with national and local regulations (e.g., air emission standards, wastewater discharge standards):

8.2.1 Dust Treatment

- Collection: Blast cabinet/room should be equipped with a pulse-jet baghouse dust collector, collection efficiency > 99%.

- Emission: Exhaust gas after treatment by dust collector should have dust concentration below regulatory limits (e.g., via stack).

- Recycling/Disposal: Collected abrasive dust (e.g., alumina fines), if pure, can be blended with new abrasive (<10% ratio), otherwise disposed as hazardous waste by licensed contractor.

8.2.2 Wastewater Treatment

Wastewater from pre-treatment degreasing, pickling, and post-treatment rinsing needs treatment process:

- Neutralization: Add sodium hydroxide solution to adjust pH to 6-9.

- Coagulation/Flocculation: Add coagulant (e.g., PAC) to remove suspended solids.

- Sedimentation: Let settle in tank for 1-2 hours, remove sludge.

- Filtration: Filter through sand filter to ensure clear effluent.

- Discharge/Reuse: Treated wastewater, meeting standards for COD, heavy metals (e.g., copper ions), can be discharged or reused (e.g., for cleaning).

8.2.3 Solid Waste Management

- Spent Abrasive: Recyclable abrasives (glass beads, steel grit) screened and reused; non-recyclable (walnut shell, soda), if biodegradable, may be disposed as general waste, otherwise hazardous waste.

- Waste Chemicals: Expired degreasers, pickling paste, passivation solutions, treated as hazardous waste by licensed contractor.

- Sludge: Sludge from wastewater treatment (containing metal ions), treated as hazardous waste, recovered or disposed by licensed contractor.

[Supplement: Occupational Health Monitoring and Circular Economy Practices]

* Health Monitoring: Conduct regular occupational health examinations for blasting operators, focusing on lung function (preventing pneumoconiosis) and hearing. This is both responsible for employees and part of corporate risk management.

* Circular Economy: Actively explore resource utilization of waste abrasive and wastewater. For example, can collected alumina dust be used in construction materials? Can treated wastewater be used for site landscaping or cooling tower makeup? This not only reduces disposal costs but also reflects corporate social responsibility, aligning with sustainable development.

Chapter 9: Industry Application Cases and Trends of Brass Sandblasting

Brass sandblasting technology is widely used across various industries. Demand differences in different fields drive continuous process innovation. Understanding industry application cases helps grasp technological development trends.

9.1 Typical Industry Application Cases

9.1.1 Decoration and Home Furnishing Industry

- Application Scenarios: Brass door handles, lamp bases, photo frame borders.

- Process Requirements: Uniform matte finish (Ra 1.2-1.6μm), scratch-free, requires clear coat protection.

- Key Parameters: H65 brass, 120 mesh glass beads, pressure 35-40 psi, distance 20 cm, blast time 12-15 s.

- Result: Surface presents fine matte, smooth touch, fingerprint-resistant (after clear coat), service life > 5 years.

9.1.2 Automotive Industry

- Application Scenarios: Brass fuel lines, radiator connectors, sensor housings.

- Process Requirements: Surface roughness Ra 1.6-3.2μm (enhancing coating adhesion), no oxide layer, salt spray resistance ≥72 hours.

- Key Parameters: H59 brass, 80 mesh aluminum oxide, pressure 45-50 psi, distance 18 cm, blast time 10-12 s; Post-treatment: Chromium-free passivation + epoxy resin coating.

- Result: Coating adhesion highest rating (5B), salt spray test 120 hours no corrosion, meeting automotive standards (e.g., ISO 12944).

9.1.3 Electronics Industry

- Application Scenarios: Brass connectors, terminals, heat sinks.

- Process Requirements: Fine surface (Ra 0.8-1.2μm), no abrasive residue, good electrical conductivity.

- Key Parameters: H62 brass, 150 mesh walnut shell, pressure 25-30 psi, distance 25 cm, blast time 8-10 s; Post-treatment: Ultrasonic cleaning + silane passivation.

- Result: Surface free of impurities, contact resistance < 5 mΩ, salt spray resistance 48 hours, compliant with electronics standards (e.g., IPC-A-610).

9.1.4 Medical Device Industry

- Application Scenarios: Brass surgical instrument components (e.g., hemostat pivot sleeves).

- Process Requirements: Burr-free surface (Ra 0.8-1.0μm), no microbial residue, requires biocompatibility.

- Key Parameters: H90 brass, 200 mesh glass beads, pressure 20-25 psi, distance 30 cm, blast time 5-8 s; Post-treatment: Ultrasonic cleaning (medical-grade detergent) + steam sterilization.

- Result: Smooth surface without defects, microbial residue after sterilization < 10 CFU, compliant with medical device standards (e.g., ISO 13485, biocompatibility per ISO 10993).

9.2 Technology Development Trends

Green Processes

- Abrasives: Promote biodegradable plant fiber abrasives (e.g., corn cob grit), recyclable nano-ceramic abrasives, reducing solid waste.

- Equipment: Develop dust-free blasting technology (e.g., advanced wet blasting), avoiding dust pollution.

- Chemicals: Replace toxic chromate passivation, promote chromium-free, low-toxicity passivators (e.g., phytate-based passivation).

Digitalization and Intelligence

- Process Control: Adopt IoT technology to monitor blasting pressure, abrasive flow, temperature etc., in real-time, enabling remote adjustment.

- Quality Inspection: Introduce machine vision systems (high-res camera + AI algorithm) to automatically detect surface defects (pitting, color variation), replacing manual inspection.

- Equipment Automation: Promote robotic blasting production lines with automatic loading/unloading systems, achieving "unmanned" production (suitable for high-volume parts).

Functionalized Surfaces

- Superhydrophobic Surfaces: Combine special abrasives (e.g., fluorine-containing) with blasting to create superhydrophobic coatings (contact angle > 150°) on brass, suitable for outdoor parts.

- Antimicrobial Surfaces: Incorporate antimicrobial agents (e.g., silver ions) during post-treatment, giving brass surface antimicrobial function, suitable for medical devices, food-contact parts.

- Conductivity-Enhanced Surfaces: Through fine blasting (Ra 0.4-0.8μm), reduce surface contact resistance, suitable for high-frequency electronic parts.

[Supplement: Cross-Industry Applications and Micro-Scale Expansion]

* Cross-Industry Application: Brass sandblasting techniques are being adapted for post-processing of 3D printed metal parts, used to remove powder and spatter, and create uniform appearance. In repair and remanufacturing, blasting is key for cleaning old brass surfaces before recoating.

* Micro-Scale Expansion: With the development of micro/nano manufacturing, micro-blasting (using very fine abrasives and precision nozzles) is beginning to be used for treating brass micro-structures in MEMS, or for cleaning and texturing microscopic cavities in brass molds, showing great potential in precision fields.

Chapter 10: Summary: Core Points and Application Recommendations for Brass Sandblasting Technology

Brass sandblasting is a systematic project involving "material adaptation - process control - safety and environmental protection". Its core lies in selecting suitable abrasives, equipment, and parameters based on the brass alloy type and application requirements, while ensuring surface quality and durability through pre-treatment and post-treatment.

10.1 Review of Core Points

- Material Adaptation: Low-zinc brass (H90) requires mild abrasives (glass beads, walnut shell); high-zinc brass (H59) can use slightly harder abrasives (aluminum oxide).

- Process Key: Parameters must balance "effect - efficiency - cost", determined优先 through sample testing; batch production requires enhanced in-process auditing.

- Quality Control: Pre-treatment cleanliness, stability of blasting parameters, and effectiveness of post-treatment protection are the three core control points.

- Safety & Environment: Must equip PPE and ventilation; wastewater and solid waste require compliant treatment to avoid environmental pollution and personnel injury.

10.2 Application Recommendations

- Small Batch / Complex Parts: Choose manual blast cabinet, paired with glass beads or walnut shell abrasive, focus on operator skill training.

- Large Batch / Standardized Parts: Choose fully automatic robotic blaster for precise parameter control, reducing labor costs.

- Decorative Parts: Prioritize glass bead abrasive, post-treatment with clear coat to enhance aesthetics and weather resistance.

- Functional Parts (e.g., conductive, corrosion-resistant): Select aluminum oxide or soda abrasive based on needs, enhance passivation or coating protection in post-treatment.

- High Eco-Requirement Scenarios: Choose chromium-free passivation, biodegradable abrasives, equip efficient dust collection and wastewater treatment systems.

[Supplement: Future Outlook for Brass Sandblasting Technology] In the future, brass sandblasting technology will increasingly focus on the integration of "precision", "intelligence", and "greenness". Through sensors, machine learning, and digital twin technology, intelligent blasting systems capable of real-time perception, autonomous decision-making, and dynamic optimization will be built, achieving "right first time" zero-defect production. Simultaneously, biodegradable abrasives and near-zero emission waste recycling technologies will become standard. Ultimately, brass sandblasting will no longer be seen merely as a manufacturing step, but as a core link in achieving product differentiation, enhancing added value, and implementing sustainable development strategies.

Steel Grit

Steel Grit

Glass Beads

Glass Beads