Copper alloys are indispensable materials in modern industries, with widespread applications, especially in electrical, manufacturing, and marine industries. This article will thoroughly analyze the four primary copper alloys—brass, copper, bronze, and white copper—examining their composition, mechanical properties, applications, and corrosion resistance, to provide valuable comparative information that aims to address readers' questions.

1. Overview of Copper Alloys

Copper alloys are materials composed of copper and other metal elements, typically designed to enhance their mechanical properties, corrosion resistance, or electrical conductivity. The four main copper alloys—brass, copper, bronze, and white copper—have diverse and widespread applications in modern industries, such as construction, electronics, shipbuilding, aviation, automotive, and even cultural arts. The properties of these alloys are finely tuned to meet various engineering and equipment requirements, depending on their intended use.

2. Composition and Properties Comparison

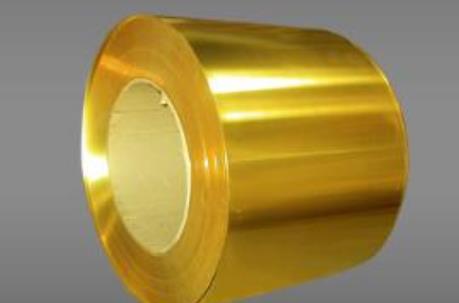

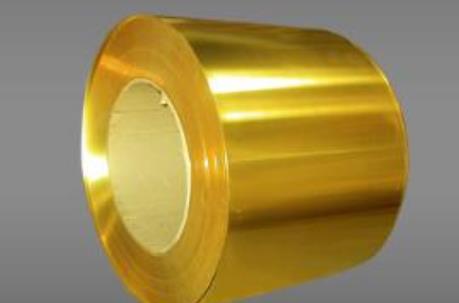

2.1. Brass

- Composition: Primarily made of copper and zinc, with zinc content typically ranging from 5% to 40%. Other elements like lead and tin may also be added to improve brass's performance.

- Properties: Brass is known for its excellent machinability and high corrosion resistance, making it ideal for daily mechanical parts and decorative items.

- Applications: Hardware, musical instruments, decorative items, etc.

2.2. Pure Copper

- Composition: Pure copper, typically containing more than 99.9% copper.

- Properties: Copper has the best electrical conductivity, along with good ductility and malleability. Due to its excellent conductivity, copper is widely used in the electrical industry.

- Applications: Wires, cables, heat exchangers, electronic components, etc.

2.3. Bronze

- Composition: Primarily made of copper and tin, but may also include aluminum, nickel, and other elements to enhance wear resistance and corrosion resistance.

- Properties: Bronze has high wear resistance and excellent corrosion resistance, especially suitable for marine environments.

- Applications: Gears, bearings, marine equipment, sculptures, etc.

2.4. White Copper

- Composition: Mainly composed of copper, nickel, and zinc, with a relatively high nickel content.

- Properties: White copper performs exceptionally well in harsh environments, offering outstanding corrosion resistance, especially in seawater and chemical environments.

- Applications: Tableware, electrical components, chemical equipment, etc.

2.5. Comparison Table:

| Alloy Type | Main Composition | Electrical Conductivity | Corrosion Resistance | Strength | Example Applications |

|---|---|---|---|---|---|

| Brass | Copper + Zinc | Moderate | High | Moderate | Hardware, Musical Instruments |

| Copper | Pure Copper (>99.9%) | Very High | Moderate | Moderate | Wires, Cables |

| Bronze | Copper + Tin/Al/Ni | Moderate | Very High | High | Gears, Bearings, Sculptures |

| White Copper | Copper + Nickel + Zinc | High | Very High | High | Electrical Components, Tableware |

3. Visual and Aesthetic Differences

Each copper alloy has distinct color and appearance, which influences their selection based not only on performance but also on visual aesthetics:

- Brass: Brass has a golden-yellow sheen, making it ideal for decorative items, musical instruments, and architectural materials.

- Copper: Copper has a reddish or purplish hue, commonly used in electrical devices and pipes where high conductivity is necessary.

- Bronze: Bronze ranges in color from deep red to green, developing a patina over time. It is often used for sculptures and marine equipment.

- White Copper: White copper has a silver-white appearance, making it suitable for electrical components and items that require corrosion resistance.

4. Functional Comparison and Specific Applications

Copper:Due to its extremely high electrical conductivity, copper is the material of choice in electrical engineering, widely used in wires, cables, heat exchangers, and other applications requiring high conductivity.

Brass:Brass's excellent machinability and high corrosion resistance make it widely used in hardware, musical instruments, and precision mechanical parts. It is an ideal material, especially for applications requiring intricate mechanical processing.

Bronze:Bronze, with its superior wear resistance and corrosion resistance, is especially well-suited for marine environments. It is used extensively in ship components, gears, bearings, and sculptures.

White Copper:

White copper, with its outstanding chemical corrosion resistance, is used in chemical industries, electrical components, and tableware, where corrosion resistance is crucial.

5. Corrosion Resistance and Durability in Specific Environments

- Bronze: Due to its excellent seawater corrosion resistance, bronze is commonly used in marine environments, such as ship parts and offshore facilities.

- White Copper: White copper excels in chemical corrosion resistance, making it ideal for chemical applications and extreme environments.

- Brass: Brass is suitable for humid environments but performs poorly in high temperatures or seawater.

- Copper: While copper has excellent electrical conductivity, its corrosion resistance is relatively weak under some corrosive conditions, and it requires careful handling in aggressive environments.

6. Manufacturing and Processing Challenges

Each copper alloy presents unique challenges in terms of processing and manufacturing. Understanding these challenges is crucial for improving production efficiency and processing quality:

- Brass: Brass is easy to process and is commonly used in hardware and decorative items, but excessive zinc content can make it brittle and affect processing.

- Copper: Copper requires special processing to prevent surface oxidation and maintain its high conductivity. Copper’s malleability makes it easier to process but may not be durable in high-strength applications.

- Bronze: Due to its high strength, bronze is difficult to process and requires the use of carbide tools. Special processing techniques are necessary to handle the challenges posed by its strength.

- White Copper: White copper typically requires complex alloying processes and surface treatments to enhance its mechanical properties and corrosion resistance.

Author's thoughts

By comparing the composition, properties, applications, and corrosion resistance of brass, copper, bronze, and white copper, we can see that each copper alloy has its own unique advantages and suitable application scenarios. Whether in electrical, mechanical, or marine fields, selecting the right copper alloy depends on specific requirements. Understanding their properties will help engineers and manufacturers make informed material choices for their projects.