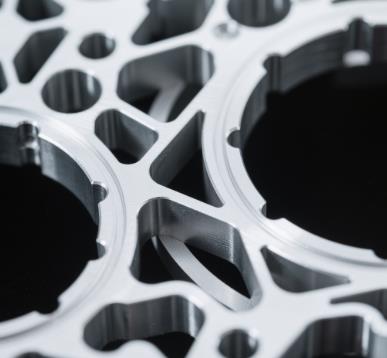

Thin-walled machining represents one of the most demanding processes in CNC manufacturing, characterized by part flexibility that leads to vibration, deformation, and accuracy deviations. Typically defined as components with wall thickness below 2mm or height-to-thickness ratios exceeding 10:1, these structures require specialized approaches to maintain dimensional stability. In aerospace applications, for instance, every kilogram reduced in aircraft weight translates to approximately $3,000 annual fuel savings, driving the need for reliable thin wall machining methodologies that don't compromise structural integrity.

Systematic Approach to Thin-Walled Manufacturing

Successful thin-walled machining demands integrated strategies across multiple manufacturing stages. Our data indicates that projects implementing comprehensive process optimization from the design phase achieve 25-35% higher first-pass success rates compared to reactive approaches.

Design Phase Considerations

Strategic reinforcement through rib implementation and temporary support structures can reduce part deformation by approximately 40%. For complex geometries, we often recommend designing sacrificial fixtures that remain during machining but get removed post-processing, providing crucial stability during cutting operations.

Advanced Fixturing Solutions

Traditional mechanical clamps frequently cause stress concentration in thin-walled components. Vacuum fixtures and conformable soft jaws distribute holding forces uniformly, while custom-designed fixtures for batch production ensure repeatable positioning. For prototyping through production runs, our CNC machining services incorporate modular fixturing systems that adapt to various thin-walled geometries.

Cutting Parameter Optimization

Parameter selection directly influences machining stability. Through extensive testing with materials ranging from aluminum alloys to engineering plastics like POM and PEEK, we've established parameter windows that maintain wall deviation within ±0.02mm while achieving surface roughness of Ra 0.6μm.

| Parameter Category | Recommended Range (Aluminum) | Performance Benefit |

|---|---|---|

| Cutting Speed (Vc) | 250-350 m/min | Reduced cutting forces, improved surface finish |

| Feed per Tooth (fz) | 0.05-0.12 mm/z | Prevention of built-up edge, maintained efficiency |

| Depth of Cut (ap) | ≤0.5mm | Minimized wall deflection through reduced cutting forces |

Thermal and Stress Management

Heat accumulation and residual stresses represent critical factors in thin-walled component distortion. Our multi-stage approach—roughing, stress relief, semi-finishing, and finishing—reduces part warpage by over 40%. High-pressure coolant (50-70 bar) effectively dissipates heat during titanium and stainless steel machining, while MQL (Minimum Quantity Lubrication) reduces cutting temperatures by 15-20% in aluminum applications.

Precision Verification Technologies

Maintaining tolerances of ±0.01-0.02mm demands advanced monitoring and compensation systems. Integrated force sensors and vibration monitoring modules enable real-time parameter adjustments, reducing cutting force fluctuations by 15-25%. In-process probing systems (such as Renishaw or Blum) provide dimensional feedback for dynamic compensation, decreasing final product deviation by over 30% and achieving first-pass yield rates exceeding 95%.

Industry Applications and Impact

Thin-walled components constitute 20-30% of precision machining demand across critical sectors. Aerospace structural elements, medical device housings, and consumer electronics enclosures all benefit from advanced thin-walled machining strategies. The transition toward lightweighting in automotive and aerospace industries makes these capabilities increasingly valuable for sustainable manufacturing. For organizations seeking to master thin-walled machining precision and stability techniques, our comprehensive guide details the integrated approach necessary for success.

Sustainable Manufacturing Integration

Modern thin-walled machining increasingly emphasizes energy efficiency and environmental responsibility. Through multi-objective optimization balancing quality, throughput, and energy consumption, we've demonstrated 8-12% overall efficiency improvements. MQL implementation reduces coolant consumption by up to 80% while extending tool life through reduced thermal shock. These sustainable practices align thin-walled machining with broader green manufacturing initiatives without compromising precision requirements.