1. 3+2 Axis Machining

3+2 axis machining, also known as "orientational machining" or "five-axis positioning machining," involves using two rotary axes (typically the A-axis and C-axis) of a five-axis machine to rotate and tilt the workpiece to a fixed optimal angle. Once in position, the workpiece is locked, and the machining is done with three linear movements (X, Y, Z) as in a traditional three-axis machining center.

Steps: Position → Lock → 3-Axis Milling

Equipment: Any five-axis machine with dual rotary axes can perform 3+2 machining. It does not require the machine to have true five-axis simultaneous control, but it does need hardware that supports rotary axis positioning. This is a very common and cost-effective five-axis application method.

2. 5-Axis Simultaneous Machining

This refers to true "continuous five-axis" machining. During the process, all five axes (X, Y, Z, A, B/C) move simultaneously and continuously, based on instructions from the CNC program. This allows the tool tip to follow complex spatial trajectories while adjusting the tool's orientation in real-time, ensuring the most optimal cutting state relative to the workpiece's surface.

Equipment: A high-end 5-axis simultaneous CNC machine is required. These machines not only feature dual rotary axes but also need a powerful CNC system capable of five-axis interpolation, RTCP (Rotating Tool Center Point), and backlash compensation to maintain the tool tip's correct spatial position.

Common Structures:

- Dual rotary table (e.g., AC rotary table)

- Dual swing head (e.g., BA swing head)

- Hybrid table + head (e.g., A rotary table + B swing head)

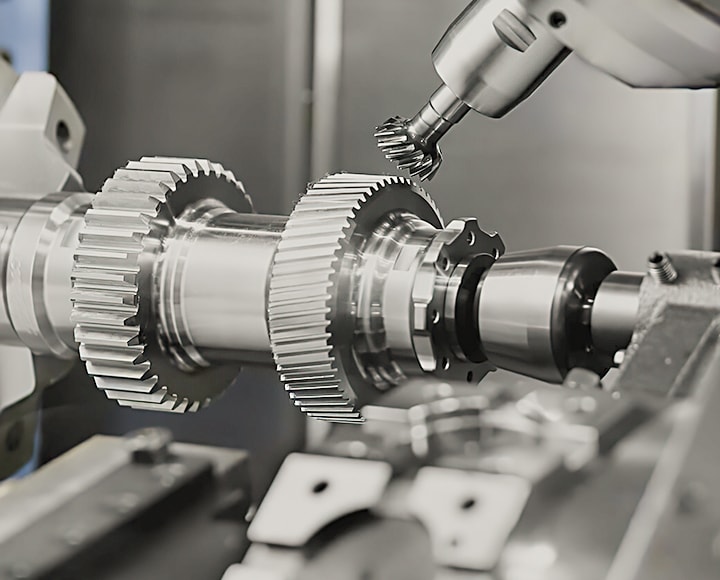

3. Turn-Mill Compound Machining

The core concept of turn-mill compound machining is the integration of functions into a single machine, reducing the need for multiple setups. A workpiece is clamped on the spindle (for turning), while one or more high-speed rotating power tools (for milling) and a secondary spindle are integrated into the machine.

During machining, the primary spindle rotates the workpiece for turning; power tools perform milling, drilling, and tapping; and the secondary spindle can take over the workpiece for rear-side machining. All of this happens in a single setup, aiming for "one machine, one complete part." The milling function is often integrated into a five-axis (3+2 or simultaneous) system.

Equipment: A turn-mill compound machining center typically includes:

- Turning spindle (can function as C-axis indexing or linkage)

- Power tools (high-speed rotating milling spindles)

- Second spindle (for part retrieval and rear-side machining)

- Y-axis (allows the power tool to deviate from the centerline)

- B-axis (a rotating tool head that tilts, enabling 3+2 or five-axis milling)

Comparison of Key Machining Methods

| Feature | 3+2 Axis Machining | 5-Axis Simultaneous Machining | Turn-Mill Compound Machining |

|---|---|---|---|

| Core Principle | Lock the rotary axes at an angle, then perform 3-axis milling. | Five axes (X, Y, Z, A, B/C) move simultaneously, adjusting the tool orientation in real-time. | Integrates turning (rotating) and milling (power tool) functions in one machine with a single setup. |

| Movement Type | Sequential: Position → Lock → 3-axis milling. | Synchronous: Five axes coordinate and continuously adjust tool orientation. | Combination of turning spindle rotation (C-axis) and milling spindle feed, often with a second spindle, Y-axis, B-axis, for compound movement. |

| Essence | A mode of five-axis machine application, not a standalone machine type. | Top-tier five-axis machine functionality. | A multifunctional integrated machine, its milling function often based on a five-axis system. |

| Key Advantages | Avoids tool interference, uses shorter, stronger tools, improves surface quality, and reduces setup time. | Allows for complex spatial continuous surface machining (e.g., impellers, turbines, precision molds). | Minimizes setup times, increases precision and efficiency, and completes highly complex parts in one setup. |

| Typical Equipment | Any five-axis machining center with dual rotary axes (vertical or horizontal). | High-end 5-axis machining centers (rotary table type, swing head type, hybrid type). | Integrated machine tool with both turning and milling spindles (e.g., turn-mill centers with B-axis and Y-axis). |

| Analogy | "Pose, then sculpt." | "Dance and sculpt simultaneously." | "A craftsman who can both turn and mill, and never lets go of the part." |

Core Differences Summary

Goals:

- 3+2 and 5-axis Simultaneous: Primarily solve issues of tool orientation and machining of complex surfaces.

- Turn-Mill Compound: Primarily addresses the integration of processes to reduce setups and improve overall efficiency and accuracy.

Relationships:

- The milling portion of a turn-mill machine is often a five-axis system, capable of both 3+2 and 5-axis simultaneous machining.

- A 5-axis machine can perform 3+2 and 5-axis machining but cannot perform turning operations.

- 3+2 machining is a subset of 5-axis simultaneous machining.

Core Value:

- 3+2: Strategic value through optimized angles to improve quality, efficiency, and avoid tool interference.

- 5-Axis Simultaneous: Capability-based value, solving the machining of complex geometries that other methods cannot handle.

- Turn-Mill Compound: Process-based value, revolutionizing traditional multi-machine and multi-fixture workflows, drastically improving precision and efficiency.

Cost Analysis

3+2 Axis Machining

- Equipment Cost: Higher than traditional 3-axis machines but much lower than top-end 5-axis and turn-mill compound machines. The most cost-effective way to enter the "five-axis domain."

- Programming Cost:

- Software: Requires CAM software with five-axis positioning capabilities (e.g., UG/NX, Mastercam, Hypermill), but without top-tier five-axis simultaneous modules, keeping software costs relatively low.

- Labor & Time: More complex than 3-axis programming, requiring engineers to understand tool orientation and workpiece positioning, but much simpler than full 5-axis programming.

- Cycle Time: Though positioning takes up some machine time, total processing time is significantly reduced by minimizing setups and utilizing efficient tools.

- Fixture Costs: Simplified, often requiring just a simple fixture for multi-face machining.

- Tool Costs: Longer-lasting, stronger tools can be used, reducing breakage risk and improving tool lifespan.

5-Axis Simultaneous Machining

- Equipment Cost: Extremely high. True five-axis machines have complex mechanical structures and high CNC system requirements, often costing 3-5 times more than equivalent 3-axis machines.

- Programming Cost:

- Software: Requires top-tier, expensive five-axis CAM software licenses.

- Labor & Time: Programming is highly complex, requiring deep understanding of tool paths, vector control, and collision avoidance.

- Cycle Time: Highest machine-hour rate, but no alternative for machining complex surfaces (e.g., impellers), making it a necessary investment for certain tasks.

- Tool Costs: Specialized cutters may be needed to achieve optimal results.

Turn-Mill Compound Machining

- Equipment Cost: The highest, with integrated turning, milling, and often additional functions like drilling, tapping, and even grinding.

- Programming Cost:

- Software: Requires specialized CAM software capable of handling both turning and milling operations, often the most expensive.

- Labor & Time: The most complex programming, requiring knowledge of both turning and milling techniques and seamless integration of both.

- Cycle Time: Typically the lowest for complex parts, as multiple processes are combined into one machine cycle.

- Fixture Costs: Extremely low, almost always requiring only standard chucks and centers.

Cost Comparison Summary

| Cost Dimension | 3+2 Axis Machining | 5-Axis Simultaneous Machining | Turn-Mill Compound Machining |

|---|---|---|---|

| Equipment Cost | Medium-High | Extremely High | Extremely High |

| Software & Programming | Medium | High | Very High |

| Cycle Time Cost | Medium | Medium-High | Usually Lowest (for complex parts) |

| Fixture & Setup Costs | Low-Medium | Low-Medium | Extremely Low |

| Tooling Costs | Medium (Standard Tools) | Medium | Medium (Specialized Systems) |

| Operator Skills & Labor | Medium-High | High | Very High |

| Suitable Production Volumes | Small-Batch, Prototypes | Small-Batch, High-Value Single Pieces | Large-Volume, High-Value Products |

| Cost Core | Strategic Savings | Capability-Based Costs | Efficiency |