CNC milling is not merely a technological upgrade of metalworking; it is a fundamental reconstruction of the manufacturing mindset. When coded instructions precisely drive micron-level cutting movements, what emerges is not just the birth of a part, but the ultimate dance of precision engineering in the digital era. In this article, we will explore what CNC milling truly is.

What is CNC Milling?

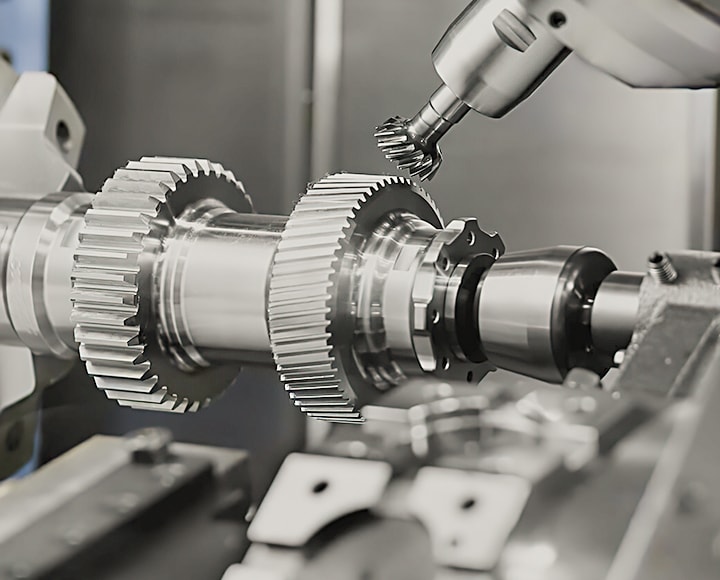

CNC (Computer Numerical Control) milling is a precise material removal process in which the movement of the milling cutter and the positioning of the workpiece are controlled by pre-programmed computer instructions. Unlike traditional manual milling machines that rely on the operator’s experience, CNC systems parse G-code instructions to drive high-precision servo motors, enabling the tool to move with micron-level precision in three-dimensional space. This digital essence allows CNC milling to handle complex surfaces, deep cavities, thin walls, and other geometries that traditional machines struggle to achieve.

Why Choose CNC Milling Machines?

According to research from the National Institute of Standards and Technology (NIST), modern CNC milling machines can achieve repeatable positioning accuracy of ±0.005 mm, far surpassing the manual operation limit of ±0.05 mm. In mass production, this precision advantage directly translates into improved yield — for example, an automotive parts manufacturer reduced its transmission housing defect rate from 8.3% to 0.7% after adopting CNC. The efficiency gains are equally remarkable: complex mold production cycles were compressed from several weeks to just a few days, while labor costs dropped by more than 40%. The synergy of precision, efficiency, and cost control forms the fundamental logic behind enterprises’ choice of CNC.

How Do CNC Milling Machines Work?

The video comes from the Internet. If there is any infringement, please contact us to delete it.

Four Core Advantages of CNC

- Conqueror of Complex Geometries: Five-axis CNC machines can handle 87° sidewall machining, avoiding secondary clamping.

- Extraordinary Stability: The Siemens 840D system can run continuously for 5,000 hours with no loss of precision.

- Digital Twin Simulation: VERICUT simulation identifies 97.6% of programming errors in advance.

- Adaptive Machining: Real-time parameter adjustments via force sensors increase tool life by 35% when machining hardened steel (HRC60).

Automatic Tool Changer (ATC)

How Does CNC Milling Ensure High-Quality Parts?

- Material Consistency: Cutting parameters for 7075 aerospace aluminum are optimized after 2,000 hours of testing.

- Process Control: A Renishaw probe automatically inspects after each process step and compensates if deviations exceed 0.005 mm.

- Environmental Conditioning: A climate-controlled workshop (20 ± 1 °C) eliminates thermal deformation, while granite beds achieve 60% better vibration absorption than cast iron.

- Smart Tools: Diamond-coated tools achieve eight times the lifespan of conventional tools when machining carbon fiber.

Rapid Model: Your Precision Manufacturing Partner

When you need to transform designs into physical parts that exceed industry standards, Rapid Model’s CNC milling services represent a concrete embodiment of technological depth. Our CNC machining centers are equipped with advanced five-axis lathes, ensuring that every part in mass production meets industry specifications.