Building Reliable Core Components for Competitive Robotics

| Industry |

Robotics / Engineering Education |

| Materials |

Aluminum alloys, Stainless steel |

| Post-Processing |

Heat treatment and finishing after CNC machining |

| Manufacturing Technology |

CNC precision machining |

| Final Deliverables |

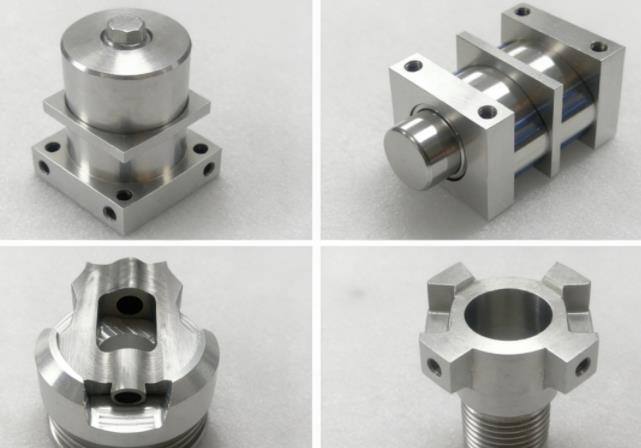

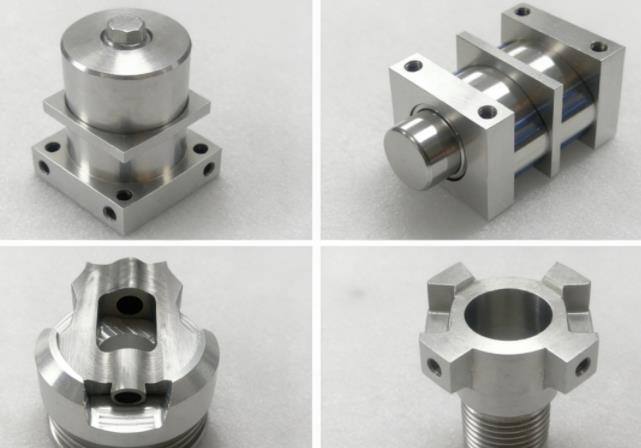

CNC-machined drive mounts, transmission shafts, and critical structural components for weapon systems |

Project Background

For the Robotics team at the Technical University of Munich (TUM), robotics competitions are not merely technical showcases—they are rigorous, real-world tests of engineering capability. As one of the competing teams in the 2025 European Robotics Challenge, team leader Lukas and his members were developing a high-performance combat robot designed to withstand high-speed impacts, sustained loads, and extreme competition environments.

However, bridging the gap between conceptual design and real-world competition introduced a critical challenge: producing high-precision, impact-resistant custom-machined components.

The Challenge: Feasible Design, Limited Manufacturing Capability

During the design phase, the team quickly identified several core components that required professional CNC machining, including:

- High-strength motor mounts to securely stabilize the drive system

- Transmission shafts capable of withstanding high-speed rotation and impact loads

- Structural components for offensive and defensive weapon systems

“We can complete prototype validation in our university labs, but the strength, tolerances, and consistency required for these final components exceeded the capabilities of our existing equipment,” Lukas explained.

These parts were not only essential for functionality—they directly determined the robot’s reliability and survivability during competition.

Finding a Solution: Recommendations from the Engineering Community

The TUM Robotics team was no stranger to competitive robotics. Through previous competitions and discussions within the engineering community, they learned about specialized manufacturers experienced in robotics and academic engineering projects.

“We heard about Rapid Model from other university robotics teams,” Lukas recalled. “They spoke very highly of the machining quality and communication efficiency, which motivated us to reach out.”

For a student team, the ideal manufacturing partner needed to meet three key criteria:

- Consistent and reliable machining quality

- A cost structure suitable for student-led projects

- A deep understanding of the unique demands of competitive robotics

The Solution: More Than Machining—Engineering Support

After gaining a detailed understanding of the robot’s operating conditions, Rapid Model developed a tailored manufacturing strategy for the team.

Technical Approach

- Precision CNC machining to ensure tight tolerances at critical interfaces

- Selection of high-strength aluminum alloys and stainless steel to balance weight and structural integrity

- Post-machining heat treatment of key components to improve impact resistance and fatigue life

- Optimization of tolerances and structural details based on competitive robotics operating conditions

Collaboration Model

Recognizing the educational value and innovative nature of the project, Rapid Model provided a flexible cooperation and support framework, enabling the manufacturing plan to remain within budget. From design confirmation to final delivery, the process was efficient and transparent, allowing the team to complete assembly and testing on schedule.

Customer Testimonial

Lukas Meier

Project Lead, TUM Robotics Team

“Before contacting Rapid Model, we had already heard a great deal of positive feedback from other university teams. Throughout the collaboration, their engineering support and responsiveness left a strong impression on us. The quotations were clear, communication was smooth, and they truly understood the requirements of robotics projects. The quality of the delivered parts fully met our expectations.”

Final Results: Proven on the Competition Floor

The robot successfully completed the entire competition. Under high-impact and high-load conditions, the CNC-machined core components performed reliably, with no structural failures or abnormal wear, significantly improving overall system robustness.

“These components form the foundation of the entire robot,” Lukas emphasized. “Without them, our design could never have made it onto the competition floor.”

Looking Ahead

The TUM Robotics team plans to further optimize the robot platform for future competitions and expand its application to higher-level international events. Rapid Model will continue to provide manufacturing support, helping student engineering teams push the boundaries of design and manufacturing.

Conclusion

This case once again demonstrates that high-quality precision manufacturing is a critical accelerator of engineering innovation. Through collaboration with university robotics teams, Rapid Model delivers more than components—it actively supports the integration of engineering education and real-world technical practice.