In the world of modern precision manufacturing, some parts are simply too hard, too complex, or too delicate for conventional machining. That’s where Wire EDM comes in. At Rapid Model, we’ve spent years refining this technique to solve challenges that other methods can't. Whether you're an engineer designing tight-tolerance molds or a buyer sourcing components that require surgical-level precision, understanding Wire EDM could change the way you approach manufacturing.

What Makes Wire EDM So Precise?

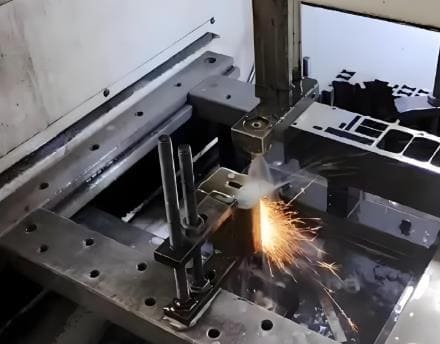

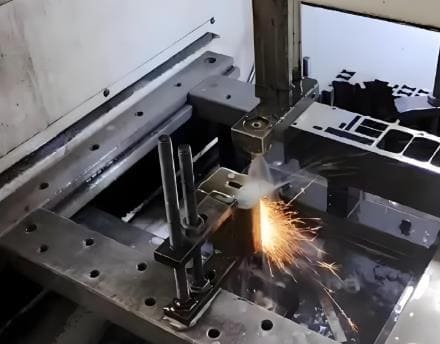

Unlike milling or turning, Wire EDM doesn't cut with physical force. Instead, it uses controlled electrical discharges to erode material. A thin wire, usually brass or coated, acts as an electrode. It never touches the part; instead, sparks generated in a bath of deionized water vaporize tiny amounts of metal. This means no mechanical stress, no tool wear, and no distortion—just pure precision.

We routinely achieve tolerances of ±0.0002" (0.005mm) and surface finishes smoother than Ra 10 µin. That’s why Wire EDM is often the process of choice for aerospace parts, medical devices, and precision tooling.

When Traditional Machining Isn't Enough

Wire EDM excels where traditional methods struggle. If you're dealing with hardened tool steel (above 60 HRC), tungsten carbide, titanium, or nickel-based alloys like Inconel, cutting them with end mills or inserts is slow, expensive, and often frustrating. EDM, on the other hand, doesn’t care about material hardness. Since it uses thermal energy instead of force, even the toughest metals can be shaped without difficulty.

Need an internal corner with zero radius? A web that's 0.2mm thick? A deep slot in a hardened die plate? Wire EDM handles these with ease. Its ability to produce intricate features without introducing stress or deformation is unmatched.

High Precision Without Compromise

Tool deflection, vibration, and thermal expansion can all degrade part accuracy in conventional machining. With Wire EDM, those problems disappear. The wire remains perfectly stable throughout the cut, and the process generates minimal heat beyond the spark zone. Multiple skim passes allow us to fine-tune dimensions and surface quality.

This makes EDM ideal not only for final parts, but also for high-precision gauges, jigs, and fixtures that need to match your CAD data exactly. If your project involves tight fits, minimal clearances, or demanding metrology standards, EDM gives you an edge.

Yes, It Works for Production Too

Wire EDM is often misunderstood as a prototyping tool only. The reality? Today’s machines feature automatic wire threading, high-speed generators, and 4-axis control, enabling fully unattended production. We run overnight jobs regularly with zero human intervention.

Many of our customers rely on us for high-volume runs of EDM parts—especially components with tapers, fragile walls, or complex contours that would require multiple operations (or just be impossible) with milling.

Understanding Its Limitations

EDM isn't the answer for every part. It only works on electrically conductive materials. Also, it’s not as fast as rough milling for simple shapes in soft metals. But if you're evaluating total cycle time, including tool changes, fixturing, and finishing, EDM often comes out ahead—especially for complex or hardened parts.

Yes, there's a kerf (typically 0.15–0.33mm), but it's predictable and fully compensated in the programming. Smaller wire diameters can be used when tighter geometry or minimal material loss is required.

Is Wire EDM Right for Your Project?

Ask yourself:

- Does the material have high hardness or poor machinability?

- Are the geometries delicate, thin-walled, or feature tight internal corners?

- Do you need tolerances in the micron range or mirror-like surface finishes?

- Is mechanical stress a concern for deformation?

- Do the parts require taper cuts or tall, narrow structures?

If you answered yes to any of the above, Wire EDM might be not just suitable—but optimal.

Why Engineers Trust Rapid Model

We do more than cut metal. Our team understands materials, tolerances, and how EDM can be best applied to your specific challenge. From prototype to production, we help our customers optimize design, avoid costly rework, and achieve results that meet both functional and aesthetic goals.

Want to know if your part is right for EDM? Send us a drawing or model. We’ll review it, provide feedback, and suggest the most efficient approach—whether it involves EDM, CNC, or a combination of both.

Let Wire EDM Work for You

If you're searching for a solution to machine tough materials, achieve impossible accuracy, or simplify complex geometry, Wire EDM may be the tool you need. Don't settle for compromised designs or time-consuming secondary operations. Contact Rapid Model and see how our precision Wire EDM capabilities can help bring your demanding projects to life.