What is Vacuum Casting?

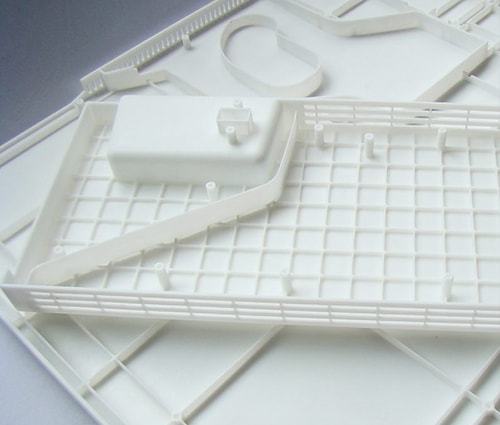

Vacuum casting, also known as polyurethane casting or silicone molding, is an advanced manufacturing process that uses silicone molds and forms parts by injecting materials under a vacuum environment. It is a low- to medium-volume production method commonly used in rapid prototyping and small batch manufacturing, especially suitable for appearance models, structural test parts, transparent components, and flexible parts.

Our vacuum casting process involves creating a silicone mold from a master pattern, then injecting polyurethane resins under vacuum to produce parts with exceptional dimensional accuracy and surface finish. This method eliminates air bubbles and ensures complete material flow into intricate details.

With over a decade of experience, our team has mastered the art of vacuum casting to deliver parts that meet the most stringent requirements for industries ranging from automotive to medical devices.

Learn More About Us