What is Die Casting?

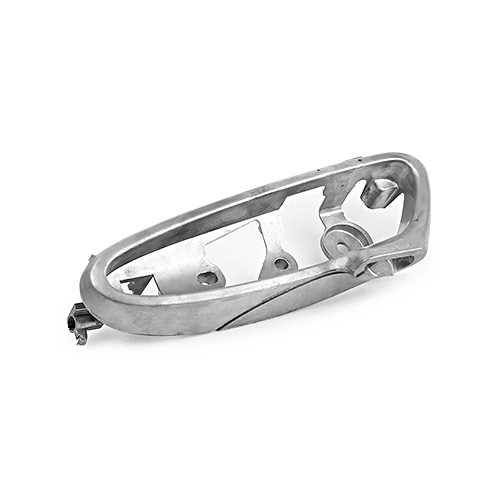

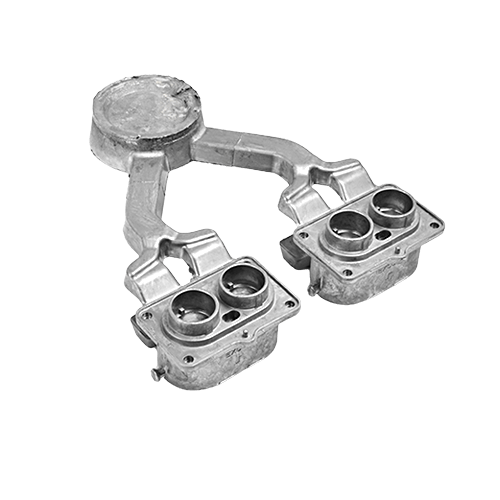

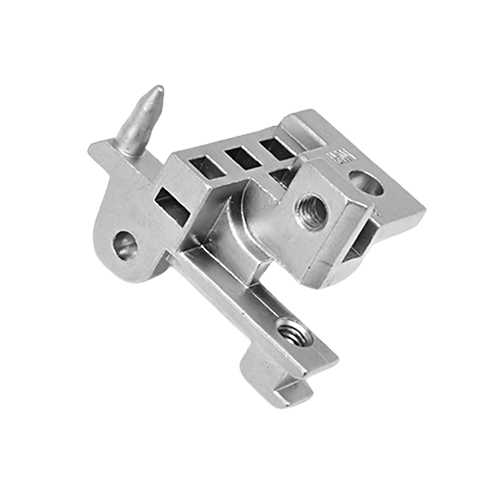

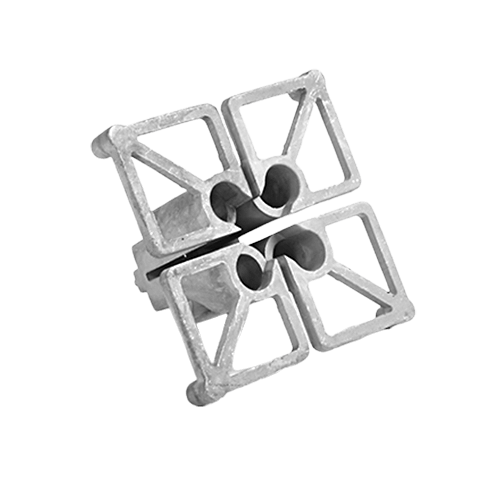

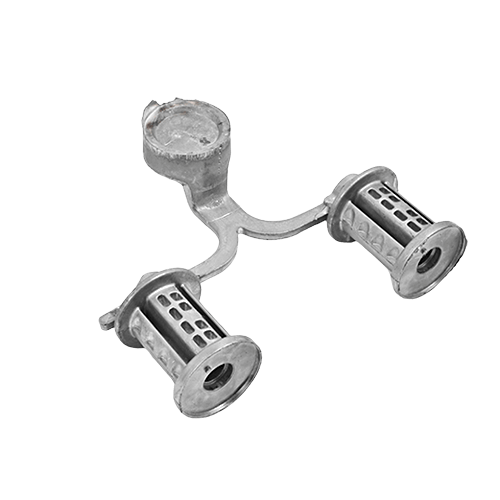

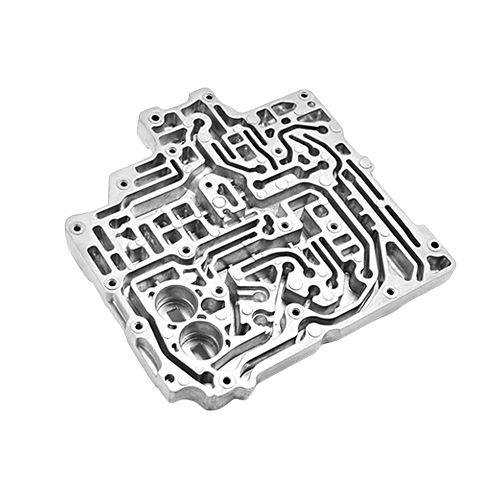

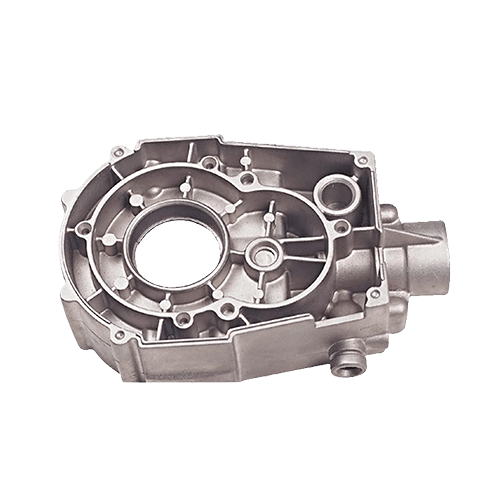

Die casting is a manufacturing process in which molten metal is injected into a metal mold and cooled under high pressure to form precise components. This process is typically used to produce complex shapes, precise dimensions, and smooth surface metal parts. Common die-casting materials include aluminum, zinc, copper, and magnesium alloys. Die casting enables the efficient, high-volume production of precision components and is widely used in industries such as automotive, electronics, aerospace, and home appliances due to its excellent mechanical properties.

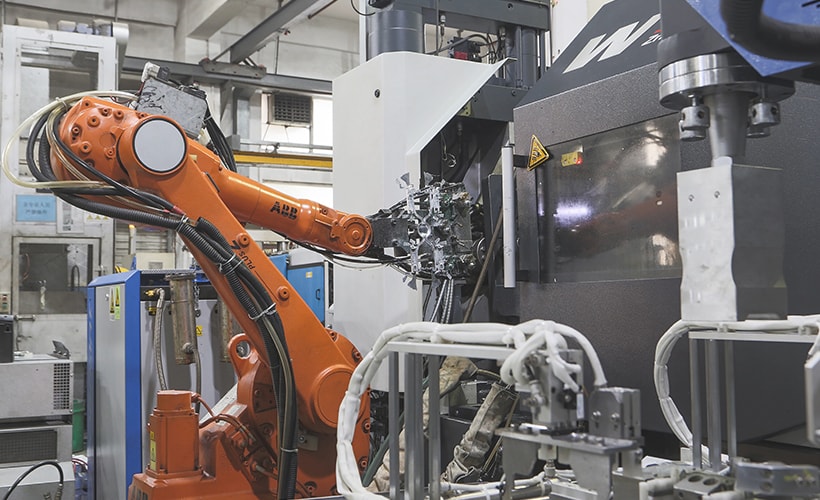

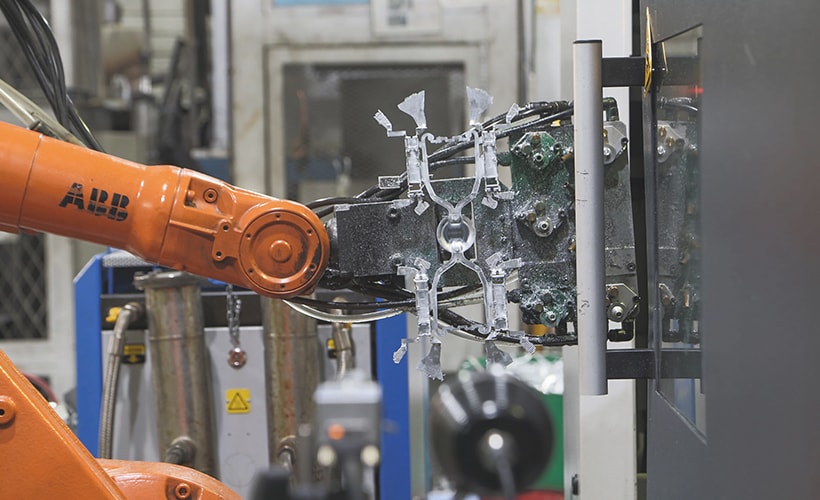

Rapid Model provides professional CNC die casting services, dedicated to delivering high-quality, high-precision metal part manufacturing for global clients. We leverage advanced die casting equipment and precise CNC machining technology to ensure that every detail meets our customers' requirements.

Learn More About Us