If you're designing parts that require clean edges, intricate patterns, and fast turnaround—laser cutting might be the solution you're searching for. Whether you're an engineer, product designer, or procurement manager, understanding what laser cutting can (and can't) do helps you make better manufacturing decisions.

At Rapid Model, we use advanced fiber and CO2 laser systems daily to produce metal and non-metal parts with tight tolerances. This article explains what laser cutting really involves, what materials it handles best, and how you can use it to save time and cost without compromising quality.

Understanding Laser Cutting—No Hype, Just Precision

Laser cutting doesn’t rely on blades or mechanical force. Instead, it focuses a beam of high-energy light onto the surface of the material. That energy is so concentrated, it instantly melts or vaporizes the material along a programmed path.

This path is defined by your CAD file. A CNC system moves either the material or the laser head to follow that geometry precisely. Assist gases (like oxygen or nitrogen) help blow away molten material, improving cut quality and protecting the optics.

Because the process is non-contact, there’s no tool wear. This means the first part is as accurate as the thousandth, making laser cutting ideal for repeatable, high-precision production.

Where Laser Cutting Works Best

You’re probably wondering when laser cutting makes the most sense. Here are the use cases where it consistently outperforms other cutting methods:

You need sharp details and tight tolerances. Laser cutting regularly hits ±0.1mm or better, even on intricate contours. It’s often the go-to for decorative panels, precision gaskets, and technical enclosures.

You want clean, burr-free edges. The process produces smooth cuts, especially on metals and plastics. This reduces or even eliminates secondary finishing steps like grinding or deburring.

You’re working with a wide range of materials. Lasers cut everything from carbon steel and stainless to acrylic, wood, polycarbonate, leather, and more. If your project involves mixed materials, it may simplify production planning.

Speed matters. For thin to medium sheet materials, lasers are lightning-fast. With proper nesting and setup, turnaround times are often faster than mechanical machining.

You care about repeatability. Because there’s no blade to dull, parts remain consistent over long runs. This is critical for industries like medical, aerospace, and electronics.

What Laser Cutting Doesn’t Do Well

No process is perfect, and laser cutting has its boundaries. Here are a few limitations to keep in mind:

1.Thick plate material. Once you go beyond 20-25mm steel, laser speed and quality drop. In those cases, waterjet or plasma cutting might be better.

2.Highly reflective metals. Materials like copper and brass reflect laser energy, which can reduce cutting efficiency or damage optics. Fiber lasers can handle these better than CO2, but experience matters.

3.Thermal sensitivity. The heat-affected zone (HAZ) is minimal, but still present. If you're working with heat-treated alloys or require zero thermal impact, be aware of this.

4.Hazardous fumes. Materials like PVC or treated wood can release toxic gases. We use advanced extraction systems, but not all providers do. Always ask.

Applications Across Industries

We’ve delivered laser-cut parts to clients in nearly every industry. Some common examples include:

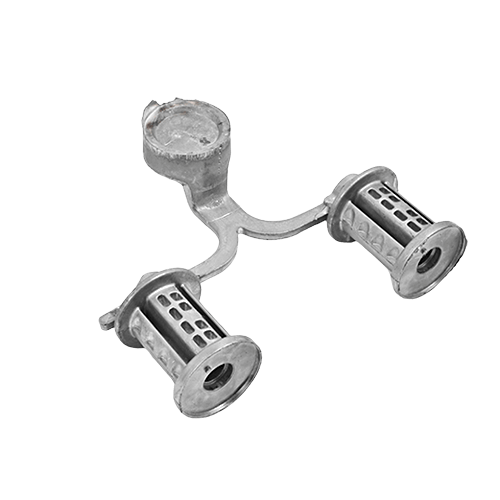

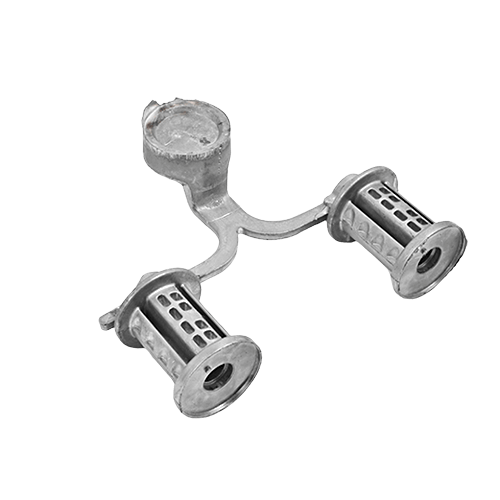

1.Aerospace: Brackets, lightweight structural parts

2.Medical: Stainless steel surgical components, device housings

3.Architecture & Decor: Custom panels, grills, lettering

4.Electronics: Precision enclosures, heat sink plates

5.Consumer Products: Appliance panels, branding elements

Choosing the Right Partner for Your Laser Cutting Needs

Laser cutting equipment is only part of the equation. You need a partner who understands materials, tolerances, and how to optimize your part for manufacturability. At Rapid Model, we help you:

1.Choose the right laser type (CO2 vs Fiber)

2.Determine proper kerf compensation

3.Select assist gases for best results on your material

4.Nest parts for cost-effective runs

5.Meet ISO 9001 quality standards

Should You Use Laser Cutting for Your Next Project?

If your part involves complex geometry, moderate thickness, tight tolerances, and a clean finish—laser cutting is likely a great fit. And if you’re unsure, we’re happy to review your drawing or model and offer a no-obligation assessment.

Reach out to the Rapid Model team to see how our laser cutting capabilities can help you move from prototype to production faster, with the accuracy your application demands.